5.3% Year-On-Year Growth! Automotive Bushing Market Size Continues To Expand, Polyurethane, Nylon And Other Plastic Materials Become Key

Specialized VisionObserved on September 22nd,Against the backdrop of continuous transformation and upgrading in the global automotive industry, the automotive bushing market is showing a vigorous development trend.Especially the demand for bushings used in automotive suspensions has surged, creating a broad market space for polyurethane, nylon, and other plastic materials.。

Zhuansu Shijie cites external news that currentlyThe global automotive bushing market size isIn 2024, it will have reached $158.28 billion, and it is expected to grow to $167.15 billion by 2025, with a further rise anticipated to $240.35 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 5.3% during this period. This growth trend is attributed to multiple factors: the increase in vehicle production provides fundamental demand support for the market; continuous advancements in automotive technology lead to higher performance requirements for bushings; and consumers' pursuit of a smoother and quieter driving experience further drives demand for high-quality bushings.

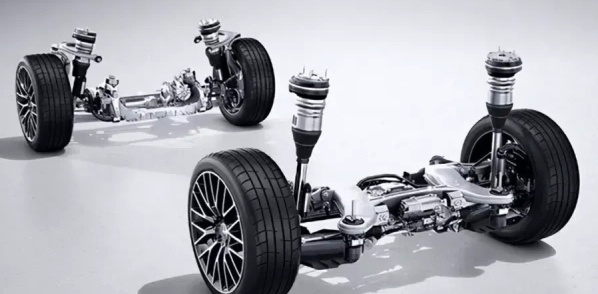

Source: Yiche

Strong demand! How important are automotive bushings?

The bushing, as a key component connecting the movable parts of the vehicle's suspension system and steering system to the chassis, is typically made of rubber or polyurethane and primarily serves as a buffer or vibration isolator. It can effectively reduce the noise and vibration generated during vehicle operation, thereby enhancing ride comfort and handling performance, while also lowering noise, vibration, and harshness (NVH).It plays an irreplaceable key role in terms of NVH (Noise, Vibration, and Harshness).

In the numerous application fields of automotive bushings,Suspension system segmentation market inThe year 2024 will hold the highest share and is the fastest-growing sector.Modern vehicles, especially electric cars and luxury cars, have an urgent need for advanced suspension systems due to their unique weight distribution and torque characteristics.In June 2024, Bosch Automotive Service Solutions launched a new toolkit specifically designed for the efficient removal and installation of robust suspension bushings, fully reflecting the industry's emphasis on suspension maintenance and performance enhancement.

The rise of advanced suspension systems has placed higher demands on bushings. Traditional bushings can no longer meet these needs, requiring superior performance to isolate vibrations and provide precise wheel motion control. For example,The latest BMW modelThe 7 Series uses an active body stabilization system.The specially designed hydraulic bushing enables millisecond-level stiffness adjustment, reducing up toThe 2024 Mercedes-Benz E-Class features an electronic active body control system that uses sensor-equipped bushings to communicate 1,000 times per second, optimizing ride comfort by 60% during body roll and improving comfort on rough roads.

Image source: Auto Home

The application of these advanced technologies has resulted in vehicles equipped with advanced suspension systems using more bushings than traditional suspension systems.These bushings are typically 15-20% heavier, and their special design and material result in costs that are 30-50% higher, directly driving the booming market for bushings used in automobile suspensions.

Distinct Advantages!Plastic materials in automotive bushingsApplication of the above content

In the material classification of automotive bushings, although rubber is still the dominant material, plastic materials such as polyurethane are gradually emerging. Polyurethane bushings are expected to have a higher compound annual growth rate than rubber during the forecast period.CAGR growth, which is primarily attributed to its outstanding performance in high-performance and durable applications.

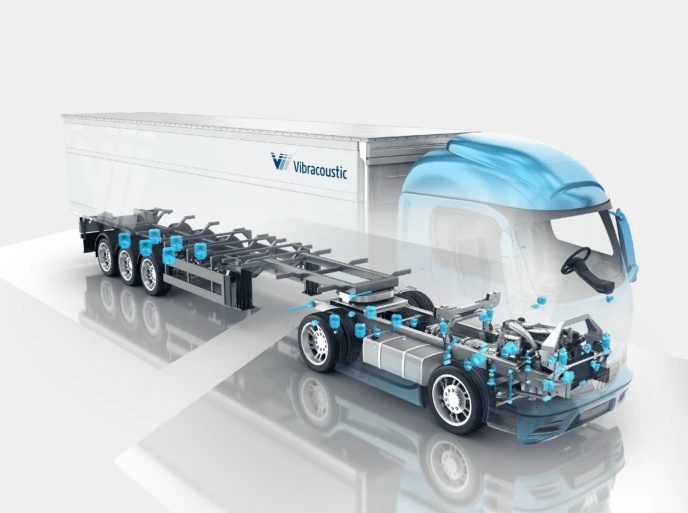

Polyurethane materials have numerous advantages, making them widely used in the field of automotive suspension bushings. They possess good wear resistance, oil resistance, and chemical corrosion resistance, allowing them to maintain stable performance under harsh working conditions. Additionally, the elastic modulus of polyurethane bushings can be adjusted over a wide range, enabling the design of bushings with different hardness levels to meet the needs of vehicles under various driving conditions.For example,Steering column bushings made of polyurethane provided by manufacturers such as Vibracoustic.It can effectively reduce vibration, providing a safer and more comfortable driving experience for the driver.

Image source: Vibracoustic

In addition to polyurethane, plastic materials such as nylon also have certain application potential in the field of automotive bushings. Nylon materials possess characteristics such as high strength, high rigidity, good heat resistance, and self-lubrication, making them suitable for manufacturing bushing components that require high strength and wear resistance. With the continuous advancement of material technology, the application proportion of nylon and other plastic materials in automotive bushings is expected to gradually increase.

Multiple factors drive!利好塑料持续下探车用

First is the drive of innovative factors, currently.The rise of intelligent sensor-integrated bushings is the dominant trend in the current market. The integration of smart technology and sensors in bushing systems is reshaping the growth pattern of the automotive bushing market. The new generation of intelligent bushings has evolved from traditional functions of noise and vibration suppression to becoming active data-driven systems that enable real-time performance optimization. For example,The active bushing technology launched by Continental's Vibration Control Division.Detect road defects through built-in accelerometers and strain gauges, and integrate with the vehicle.ECU communication can instantly adjust bushing stiffness, reducing cabin vibration by up to 50% in electric vehicles.Tenneco intelligent bushing platform utilizes machine learning algorithms to predict component wear.Implement proactive maintenance and extend the lifespan of the bushing.These innovative technologies place higher demands on plastic materials while also providing a broad space for the application of plastic materials in smart bushings.

And, with the increase ofThe rapid adoption of electric vehicles and autonomous driving cars is accelerating the transformation of the automotive bushing market. Electric vehicles use silent power systems, which amplify the perception of road noise, thus requiring bushings that actively cancel noise, and plastic materials have certain advantages in sound insulation and noise reduction.TeslaThe Cybertruck is equipped with sensor-containing bushings.Real-time data can be used to adjust damping forces based on load and terrain, which may involve the use of plastic materials with good sound insulation properties. Autonomous vehicles require ultra-high-speed vibration control to ensure the reliability of onboard sensors, prompting automotive manufacturers to seek better-performing bushing materials. Plastic materials, with their unique performance characteristics, have become one of the important choices.

Source: Tesla

In addition,The Asia-Pacific region, as the largest automotive bushing market in the world,The dominance of 2024 is attributed to the rapid growth of the automotive industry in the region.China and Japan have developed automotive parts industries and are continuously increasing investments in advanced automotive activities, driving the growth of the automotive bushing market.Simultaneously, supportive initiatives promoted by countries such as India have facilitated the development of advanced manufacturing facilities. The increase in industrial activities has driven a surge in demand for commercial vehicles, subsequently expanding the automotive bushing market size. Europe and North America also hold significant shares in the automotive bushing market due to their numerous large automobile manufacturers and strong R&D capabilities. The high demands for automotive performance and comfort in these regions compel automakers to continuously adopt new materials and advanced technologies, providing a favorable market environment for the application of plastic materials in automotive bushings.

Epilogue:

Although the market for automotive suspension bushings has a promising outlook and plastic materials are also facing development opportunities, there are still some challenges. Fluctuations in raw material prices and supply chain disruptions are key factors restraining market growth.

Automotive bushings mainly rely on materials such as natural rubber, polyurethane, and synthetic rubber, which are heavily dependent on the global commodity market and logistics networks. Recent geopolitical tensions, climate challenges, and post-pandemic economic changes have exacerbated price volatility and supply instability, directly impacting manufacturers' profitability and their ability to meet growing demand. For example, natural rubber has experienced significant price increases due to supply constraints in major producing countries, while synthetic rubber has also seen cost rises due to fluctuations in oil prices and geopolitical conflicts.

However, challenges and opportunities coexist. The integration of smart bushings with IoT and sensor technology brings transformative opportunities to the market. Developing smart bushings with integrated sensors to achieve real-time monitoring of wear, vibration, and performance aligns with the automotive industry's transition towards connected, automated, and predictive maintenance solutions.

Plastic materials have unique advantages in achieving these smart functions. For example, by adding special additives or nanomaterials to the plastic, it can have good conductivity and sensing properties, thus meeting the needs of smart bushings.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track