3D Printing Black Technology Illuminates the Future of Low-Altitude Economy | Formnext Asia Shenzhen Unlocks the Aerial Manufacturing Code

Recently, the National Digital Design and Manufacturing Innovation Center in Wuhan unveiled continuous carbon fiber 3D printing technology. The strength of the printed parts rivals that of metal, while their weight is only 1/8 that of steel of the same volume, providing a revolutionary lightweight solution for low-altitude economic equipment such as drones and eVTOLs.

On the same day, Hubei Yufei Additive Manufacturing announced the trial operation of its first two intelligent metal 3D printing production lines. Its independently developed three major intelligent monitoring systems (morphology, temperature field, and stress-strain monitoring) enable all-dimensional intelligent control of the manufacturing process, significantly improving the yield rate. This will provide core materials and cutting-edge process support for high-end equipment manufacturing in the low-altitude economy sector.

These two breakthrough advancements collectively signify that the application of 3D printing technology in China's low-altitude economy sector has entered a new stage. From material innovation to intelligent manufacturing, comprehensive upgrades have been achieved, bringing unprecedented strength-to-weight ratios and design freedom to aircraft manufacturing. This will strongly promote the low-altitude economy industry towards high-quality development.

The Formnext Asia Shenzhen exhibition will be held from August 26th to 28th at Hall 5 of the Shenzhen World Exhibition & Convention Center (Bao'an New Venue).It will become an important window to observe this technological revolution. By then, it will gather...Yingpu 3D, HP, Yimai Intelligent, Hanbang Laser, Chuanglian 3D, Xihe Additive, Zhongxian 3DLeading exhibitors with breakthrough applications in this field. These companies, each with their unique technological solutions, collectively demonstrate the tremendous potential of 3D printing technology in driving the development of the low-altitude economy.

Booth Number: C61

Yingpu 3D

Yingpu 3D demonstrates significant advantages in lightweight and high-performance structural component manufacturing for drones, thanks to its leading SLS (Selective Laser Sintering) 3D printing technology and high-performance material solutions. By utilizing materials such as carbon fiber reinforced nylon (Precimid1174Pro CF) and glass fiber reinforced nylon (Precimid1176Pro GF30 BLK), Yingpu has successfully achieved extreme weight reduction and performance enhancement for drone components—for example, a topologically optimized frame weighing only 6 grams, as well as complex quadcopter parts that have passed rigorous testing. Their technology not only solves the challenge of supporting complex structures in traditional manufacturing, but also significantly improves the strength, rigidity, and environmental adaptability of parts, fully meeting the demands of high-requirement scenarios such as rescue and reconnaissance. In the future, Yingpu 3D will continue to promote the deep integration of 3D printing technology with the drone industry, driving the sector toward greater intelligence and higher performance.

Booth Number: D21

HP's Multi Jet Fusion (MJF) 3D printing technology is driving innovation in the drone industry with its high-performance materials (such as PA12, TPU), ability to manufacture complex structures (such as lattices and topology optimization), and rapid production advantages. The American company Blueflite has used MJF technology to reduce the weight of drone components by 25% while enhancing their strength and surface quality. Unusual Machines employs this technology to achieve highly durable FPV drone components. Swiss company Inverto Earth uses MJF for the rapid customization of seed-deploying components adapted to different seeds. Indian company VECROS leverages its support-free printing and fine surface processing to optimize autonomous drone design. Compared to traditional manufacturing (such as carbon fiber processing, FDM/SLA printing), MJF technology significantly shortens the development cycle (from several weeks to a few hours), reduces production costs, and supports rapid iteration, making it a key technological support for the lightweight, high-performance, and commercial deployment of drones.

Booth No.: A32

Yi Mai Smart

Yimai continues to make breakthroughs in the high-performance materials 3D printing field. The UAV components 3D printed with high-performance carbon fiber reinforced PPS/PPA materials are becoming key drivers for industry breakthroughs.

- Ultimate lightness and strength: Carbon fiber reinforcement enables a weight reduction of over 30% in certain components, helping to improve endurance and load capacity.

Fearless of extremes: PPS is resistant to high temperatures and corrosion; PPA has high toughness and fatigue resistance, calmly coping with severe cold and scorching heat, as well as salt spray corrosion.

- Stable and durable: Low thermal expansion coefficient ensures dimensional accuracy and consistent long-term flight performance.

- Rapid iteration: Complex structures go from drawings to test flights within 72 hours, improving development efficiency by several times.

- Customization on Demand: Small batch production with zero mold cost, flexibly adapting to various scenarios such as inspection, logistics, and emergencies.

Integrated molding: reduces assembly nodes, making the structure more reliable and maintenance simpler.

Carbon fiber PPS/PPA combined with 3D printing technology is redefining the performance boundaries and manufacturing speed of drones, injecting strong innovative momentum into the low-altitude economy.

Booth Number: C36

Han's Laser

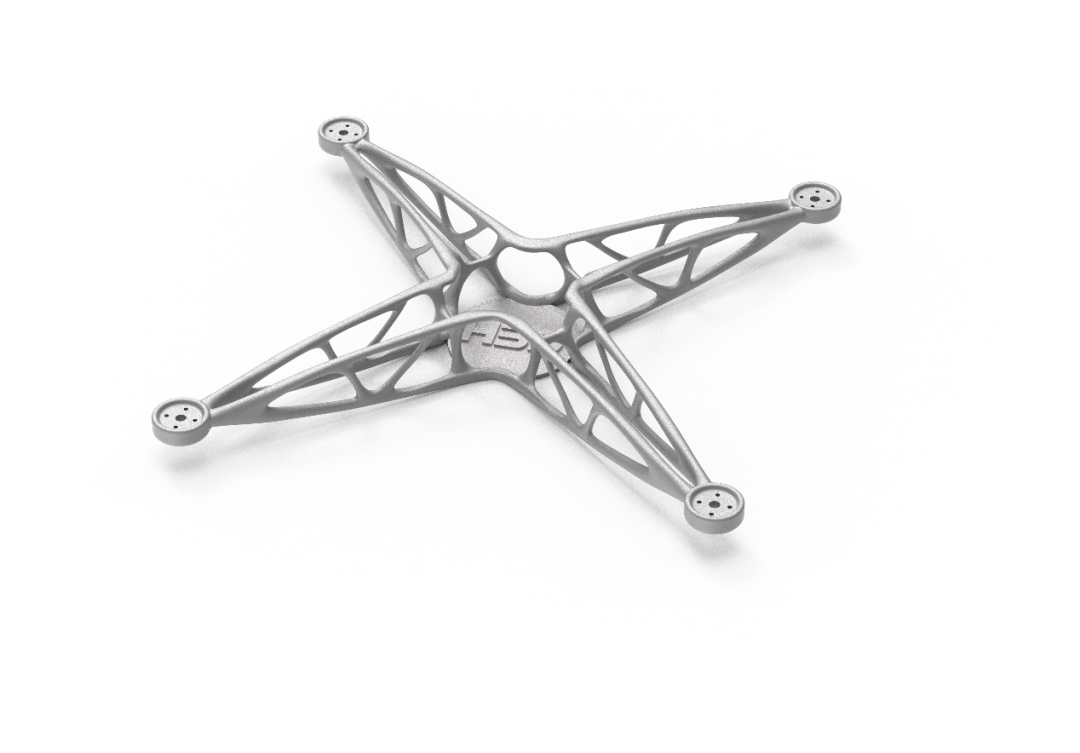

In low-altitude flight applications, metal 3D printing technology is playing an important role. It offers high design freedom, can handle complex parts, and has lightweight characteristics, reducing weight and enhancing endurance capabilities. Additionally, it allows for customized production of aircraft components to meet diverse needs. Hanbang Laser's drone bracket adopts a bionic structural design, integrating topology optimization elements for lightweight design, which can reduce the drone's own weight by more than 30% while ensuring structural strength and performance. This improves carrying capacity, reduces energy consumption, and lowers operating costs.

Booth No.: D75

Chuanglian 3D

Chuanglian Sanwei Technology (Qingdao) Co., Ltd., referred to as "Chuanglian Technology," focuses on the research and development, production, and sales of high-precision FFF 3D printing equipment. The company is dedicated to providing efficient, precise, and reliable 3D printing solutions for global industrial clients in fields such as low-altitude economy (drones), intelligent robotics, automotive manufacturing, medical devices, automation equipment, and consumer electronics.

Booth Number: B39

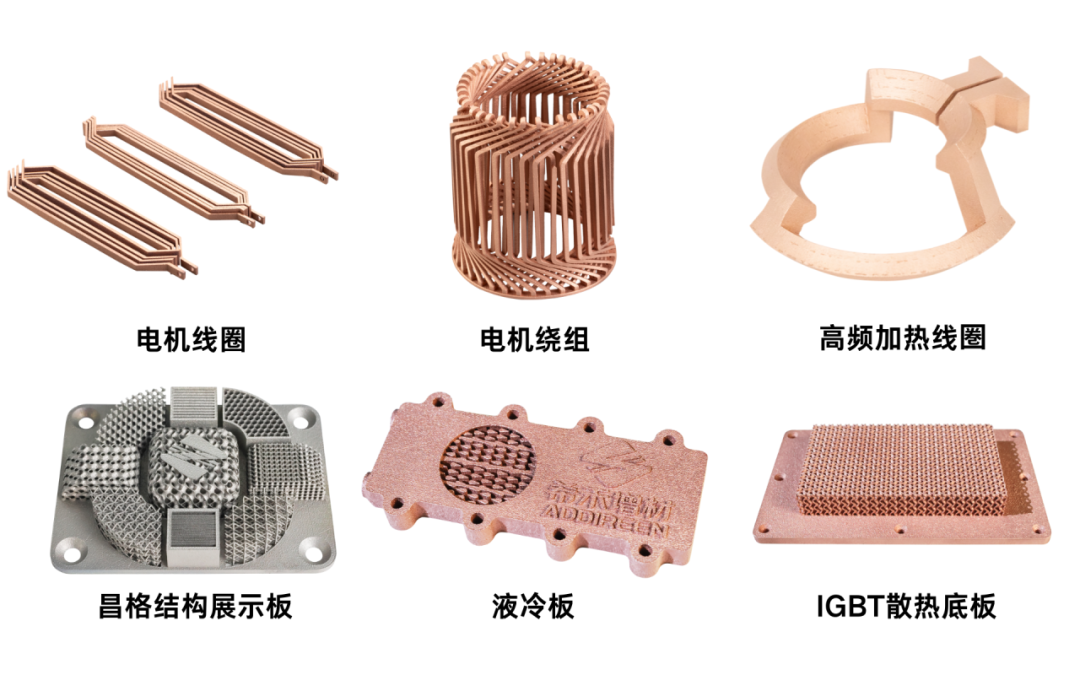

XiHe Additive

ADDIREEN will be showcasing at Formnext Asia Shenzhen, exhibiting metal 3D printing products and solutions, with a focus on promoting the engineering applications of green laser metal 3D printing in eVTOL and other aircraft. They offer integrated manufacturing solutions for lightweight, thermal management, and structural integration. As the first company in China specializing in green laser metal additive manufacturing, ADDIREEN develops high-power green laser technology to provide precision printing equipment and services for highly reflective metals, refractory metals, and conventional metals. The company is dedicated to addressing industry challenges such as material compatibility and printing efficiency, promoting the large-scale application of green laser metal additive manufacturing and advancing sustainable intelligent manufacturing.

Zhongxian 3D

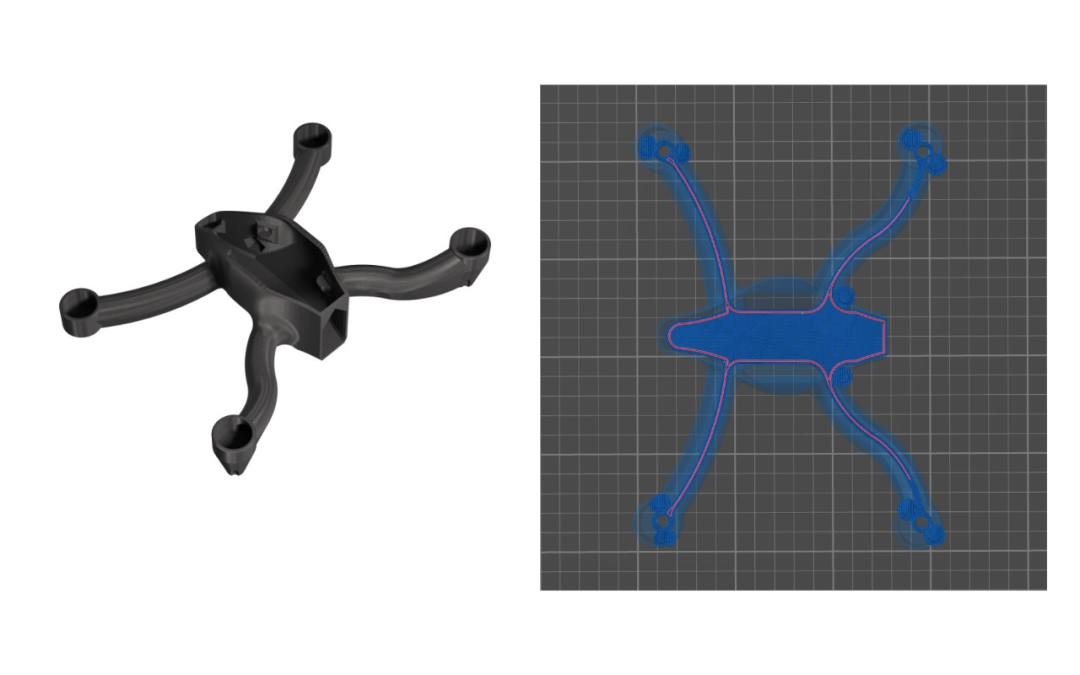

Zhongxian 3D focuses on developing cutting-edge composite material 3D printing systems and integrated solutions, aiming to promote the development of customized, high-efficiency composite material manufacturing in various industries such as aerospace, automotive manufacturing, industrial tooling, education and research, as well as electronics and electric sectors. For UAV components, it uses its self-developed slicing software Bulber to conduct fiber force flow simulation, achieving optimal fiber placement, which allows the final parts to be lightweight while delivering enhanced performance.

Formnext Asia Shenzhen

As the scale of the low-altitude economy is expected to grow from 505.95 billion yuan in 2023 to a trillion yuan by 2026 (data source: MIIT CCID Research Institute's "China Low Altitude Economy Development Research Report (2024)"), the breadth and depth of 3D printing technology applications in this field will continue to expand. The report by the MIIT CCID Research Institute indicates that China's low-altitude economy growth rate has reached 33.8%. This rapidly growing market will provide ample development opportunities for additive manufacturing enterprises. In the future, with the further integration of AI technology and 3D printing, as well as the improvement of airworthiness certification systems, 3D printing is expected to become an indispensable core technology in the low-altitude economy industry chain. The Formnext Asia Shenzhen Exhibition will become an important milestone in the development of this field, establishing an international platform for technical exchange and industrial cooperation.

From August 26-28, let's gather at Hall 5 of the Shenzhen World Exhibition & Convention Center to witness the dawn of a new era in aerial manufacturing! From lightweight drone components to large eVTOL structures, from intelligent monitoring systems to innovative material applications, Formnext Asia Shenzhen will comprehensively showcase how 3D printing technology empowers the low-altitude economy, driving the industry towards more efficient, smarter, and more sustainable development.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track