2025 Polyurethane Innovation Award Shortlist Announced

On August 13, 2025, the Center for the Polyurethanes Industry (CPI) of the American Chemistry Council announced that Algenesis Labs’ Soleic® and ICP’s HandiFoam® E84 have been shortlisted for the 2025 Polyurethane Innovation Award.

Soleic® from Algenesis Labs is a bio-based polyester polyol, and HandiFoam® E84 from ICP is a low-pressure, two-component spray polyurethane foam system.

The Polyurethane Innovation Award enjoys a prestigious reputation throughout the polyurethane industry. This annual honor aims to recognize the most creative and cutting-edge commercial technologies within the polyurethane sector that address some of the industry's challenges. The 2025 Polyurethane Innovation Award will honor companies and individuals who have introduced new products, technologies, or initiatives to the market between June 2023 and June 2025.

Jason Sloan, Director of the Center for the Polyurethanes Industry (CPI) of the American Chemistry Council, stated: "Each year, CPI is honored to present this highest technical award in the industry to recognize the spirit of innovation that drives the polyurethane industry forward and to showcase how these efforts help address some of the world's most challenging problems. We congratulate Algenesis Labs and ICP for being finalists in this year's competition."

Algenesis Labs' Soleic®

Soleic® is a bio-based polyester polyol that not only meets the performance requirements of traditional polyurethane applications but also addresses one of the most urgent environmental challenges of our time: microplastics. Algenesis Labs has developed bio-based polyols, bio-based polyurethane foams, and bio-based thermoplastic polyurethanes (TPU) derived from algae and non-food plants, and brings them to market through its B2B material brand Soleic®.

Algenesis Labs' Soleic® bio-based polyester polyol has been certified by the USDA BioPreferred program with a 100% bio-based content. Using algae and non-food plants as raw materials, it does not compete with food sources or lead to deforestation. Algenesis' unique Soleic™ bio-based polyester polyol can be used to manufacture soft polyurethane foams, which are ultimately applied in shoe midsoles and insoles. It can also be used to produce bio-based TPU, which is ultimately applied in breathable waterproof textiles and injection-molded products such as phone cases. The original intention of Algenesis Labs in creating Soleic® bio-based polyester polyol is that the end products made from it can completely biodegrade at the end of their lifecycle in compost, soil, and marine environments, breaking down into carbon dioxide and biomass, thus avoiding long-term residues in the ecosystem.

Notably, on August 4, 2025, Algenesis Labs announced the official commissioning of its pilot plant for bio-based isocyanate (Bio-Iso™). This plant will produce the world's first 100% plant-based isocyanate. By combining bio-based isocyanate (Bio-Iso™) with its Soleic® bio-based polyester polyols, it is now possible to produce 100% bio-based thermoplastic polyurethane (TPU).

ICP's HandiFoam® E84

HandiFoam® E84 spray polyurethane foam insulation is a low-pressure, two-component spray polyurethane foam system designed to maximize efficiency and reduce labor costs. It achieves seamless and uniform coverage, effectively seals air, and enhances energy efficiency. Formulated with next-generation HFO technology, HandiFoam® E84 is suitable for various seasonal conditions and maintains industry-leading foam dimensional stability, consistent reactivity, and insulation performance throughout its 24-month shelf life. HandiFoam® E84 is also UL GREENGUARD Gold certified.

In 2024, a total of three companies were shortlisted. Ultimately, Woodbridge's TrimVisible™ BIO automotive seat polyurethane foam won the 2024 Polyurethane Innovation Award.

TrimVisible™ BIO by Woodbridge

Canadian polyurethane foam manufacturer Woodbridge has developed a process that converts wood processing residues into high-purity biochar and incorporates it into the company’s polyurethane seat foam chemistry. This new product, called TrimVisibl™ BIO, is able to reduce the cradle-to-gate CO2 footprint of seat foam without compromising material properties, performance, or comfort.

The original TrimVisibl™ (known for its black color) was launched as a molded seat foam solution that offered process improvements and reduced the overall cost of seat systems. TrimVisibl™ LE is the second-generation product, setting the benchmark for low volatile organic compounds (VOC) and low odor performance in the industry. TrimVisibl™ BIO is the third-generation product.

Mike Irwin, Vice President of Advanced Products and Chemical Technology at Woodbridge, stated: "We are thrilled that Woodbridge has received the 2024 Polyurethane Innovation Award. Our scientists have developed a proprietary process that seamlessly integrates bio-carbon into the chemistry of polyurethane seat foam. The end result is TrimVisible™ BIO, a new product that reduces cradle-to-gate carbon dioxide (CO2) emissions while maintaining the material characteristics, performance, and comfort of seat foam. This innovative technology is a key step in significantly reducing the carbon footprint of vehicles throughout their entire lifecycle."

The other nominees for 2024 include:

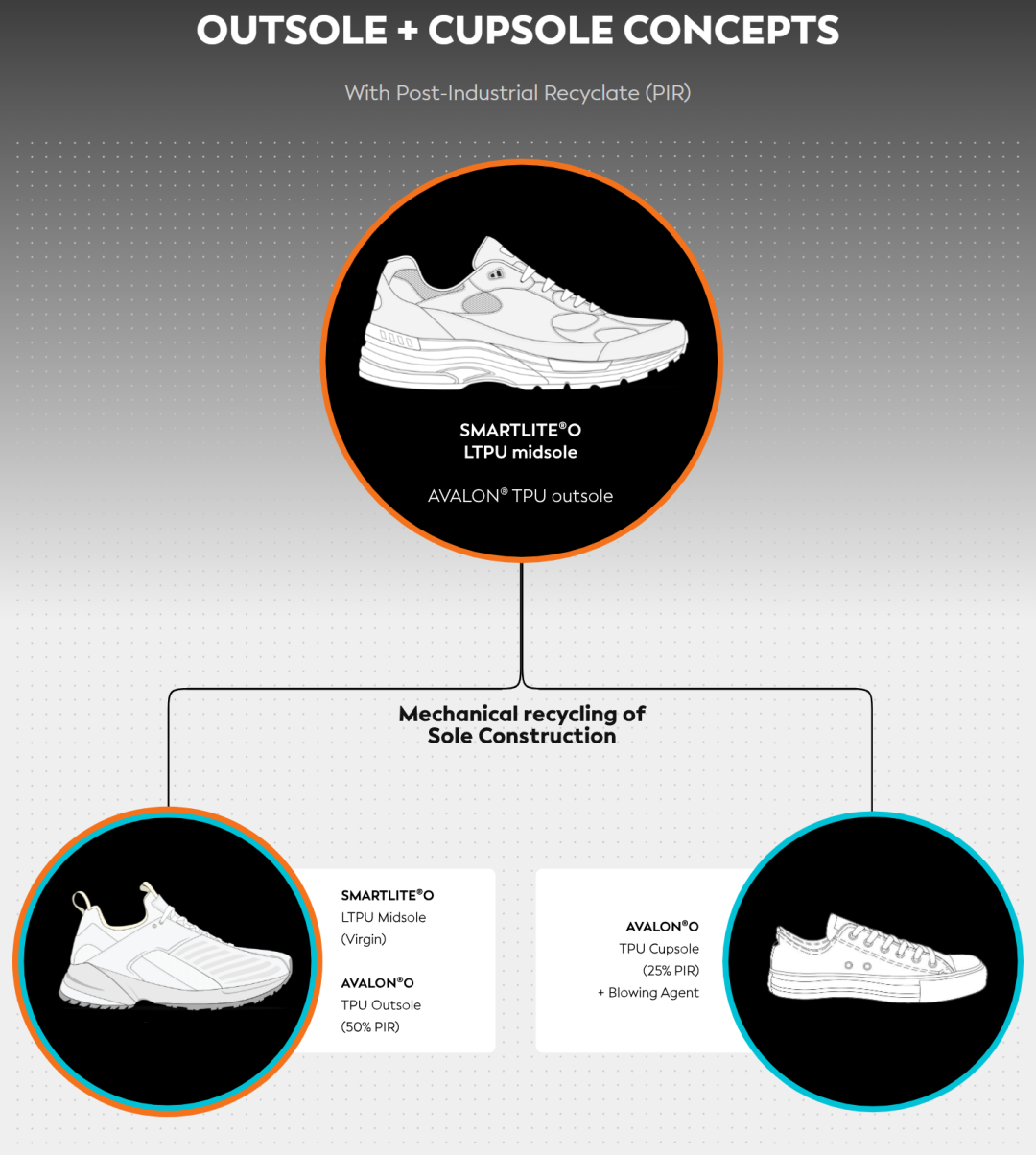

Huntsman's SMARTLITE® O LTPU

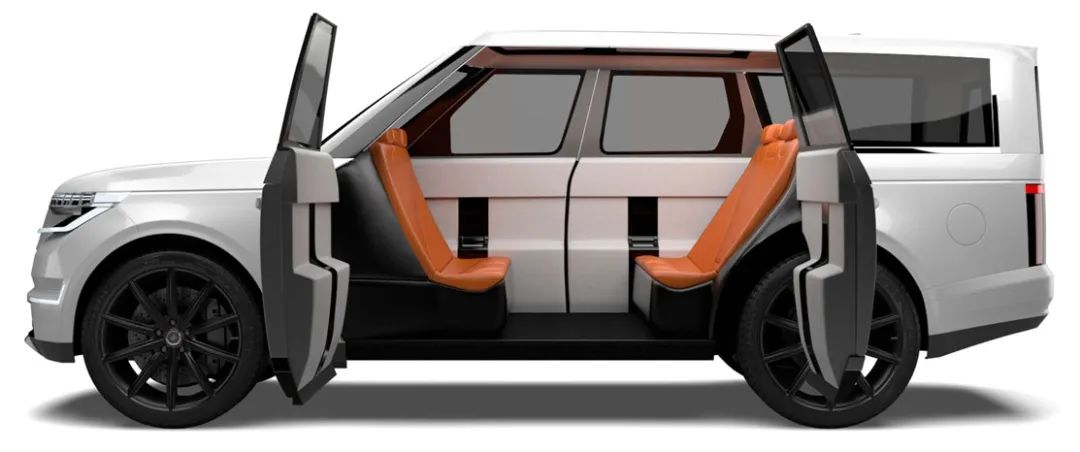

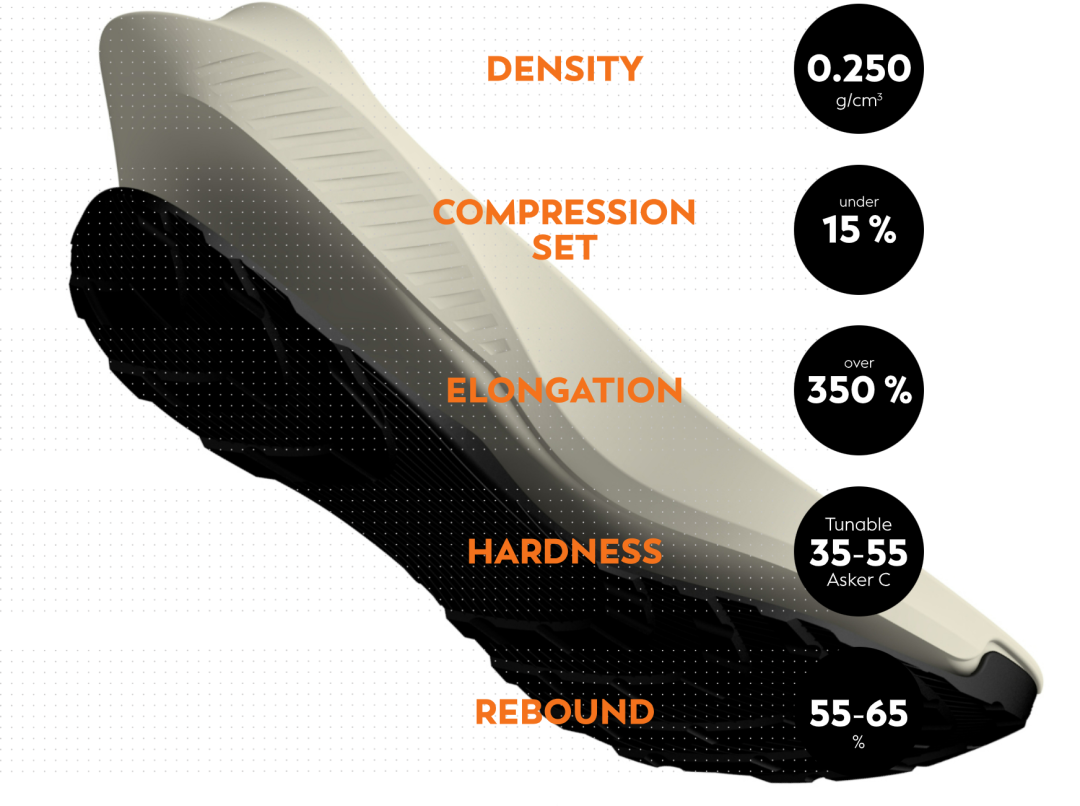

Huntsman has developed liquid thermoplastic polyurethane (LTPU) for the first time in the footwear industry, enabling the rapid production of high-performance midsoles and meeting the recycling goals of sports and leisure footwear brand manufacturers.

The SMARTLITE® O LTPU system is easier to use than expandable TPU, which requires complex procedures such as supercritical foaming and steam heating molding. It can be processed in a single step, significantly reducing water and energy consumption, as well as waste and carbon emissions. Crucially, Huntsman's SMARTLITE® O LTPU system allows for recycling of waste generated during industrial production and post-consumer use.

The main advantages of SMARTLITE® O LTPU:

- Easy processing: The SMARTLITE® O LTPU system can be processed on low-pressure casting machines, making it simple to use and scalable, which helps to simplify footwear manufacturing. With in-situ polymerization, adhesive-free bonding between the midsole and TPU outsole, and fast demolding speed, the SMARTLITE® O LTPU system offers a very short processing cycle time.

- High Performance: Huntsman's SMARTLITE® O LTPU system has a density of 250 kg/m³ and can produce outstanding hydrolysis-resistant midsoles, providing long-lasting cushioning comfort with a rebound rate of over 50%.

▪ Circularity: The SMARTLITE® O LTPU system is an ideal solution for some brands that wish to use circular midsole materials and reduce the carbon footprint of the manufacturing process without compromising performance or quality. To support the circular economy, with the right post-processing infrastructure, outsoles made with SMARTLITE® O LTPU midsoles and TPU outsoles can be recycled. For example, manufacturers can mix industrially post-consumer recycled SMARTLITE® O LTPU components with virgin TPU to produce new outsoles and cupsoles. Huntsman can also produce a bio-based version of this material.

Design freedom: For footwear designers, the SMARTLITE® O LTPU system opens up new creative opportunities by providing enhanced surface clarity without silver lines or popcorn effects. It is also easy to color and create striking gradient effects.

Incorez's Aldirez® A

Incorez, a subsidiary of Sika, has launched Aldirez® A, an innovative aldehyde-amine latent curing agent designed to address challenges encountered in moisture-cured polyurethane and polyaspartic coatings. Aldirez® A first reacts with water and then with isocyanates, thereby preventing the generation of carbon dioxide. The intermediate formed in this reaction subsequently accelerates the reaction between isocyanates and polyols, offering significant advantages such as faster curing times, excellent aesthetics, and the capability to apply polyurethane coatings under challenging atmospheric conditions like high humidity and extremely low temperatures.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track