2025 K Show Highlights | Fu Chun Shin Group's All-Electric Molding Solutions Shine in Europe

The world's largest rubber and plastics exhibition, K 2025, officially opened spectacularly on October 8 in Düsseldorf, Germany! A total of 3,257 exhibitors from around the world and numerous concurrent events together ignited this annual event in the global rubber and plastics industry.

FCS Fuchuanxin Group showcases under the theme of "Smart Manufacturing × Sustainable Practices."Hall12 / B80Exhibiting a variety of all-electric molding equipment, combined with recycled materials, micro-foaming technology, and intelligent factory systems, showcasing green molding solutions that encompass monochrome and bicolor, precision and energy-saving, and multi-material applications, fully responding to the global market's demand for efficiency, low carbon, and intelligence.

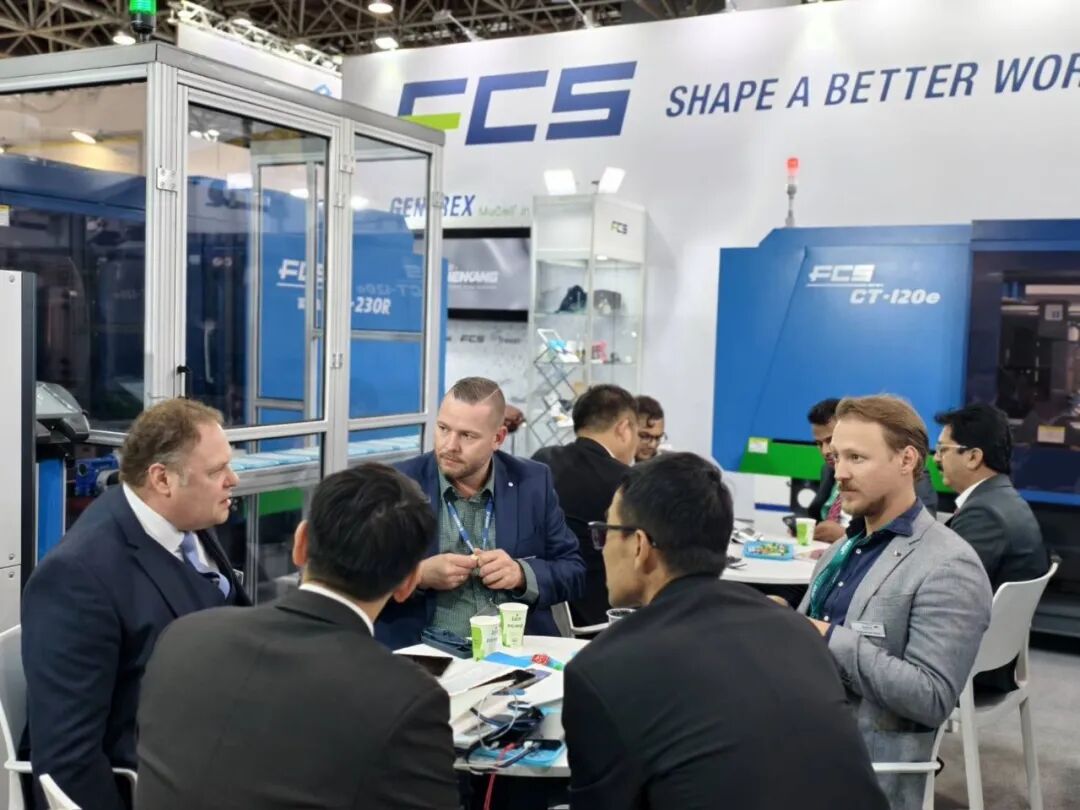

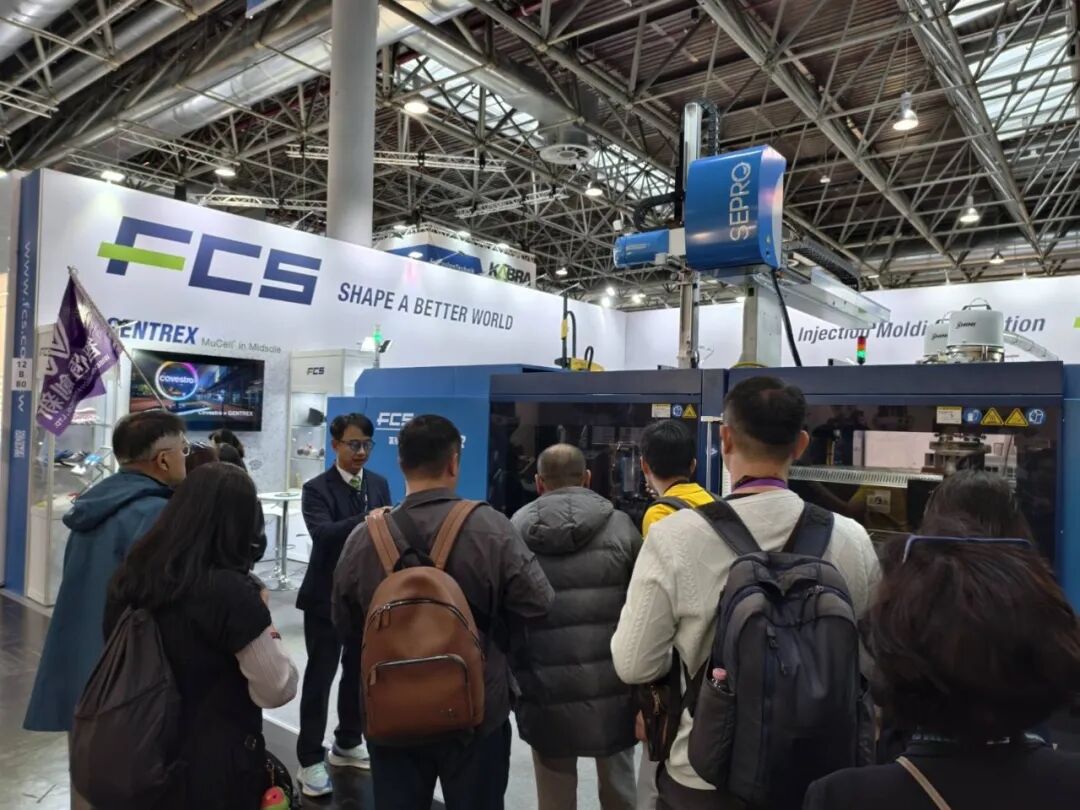

On-site coverage of the exhibition booth.

Exhibition Machine Introduction

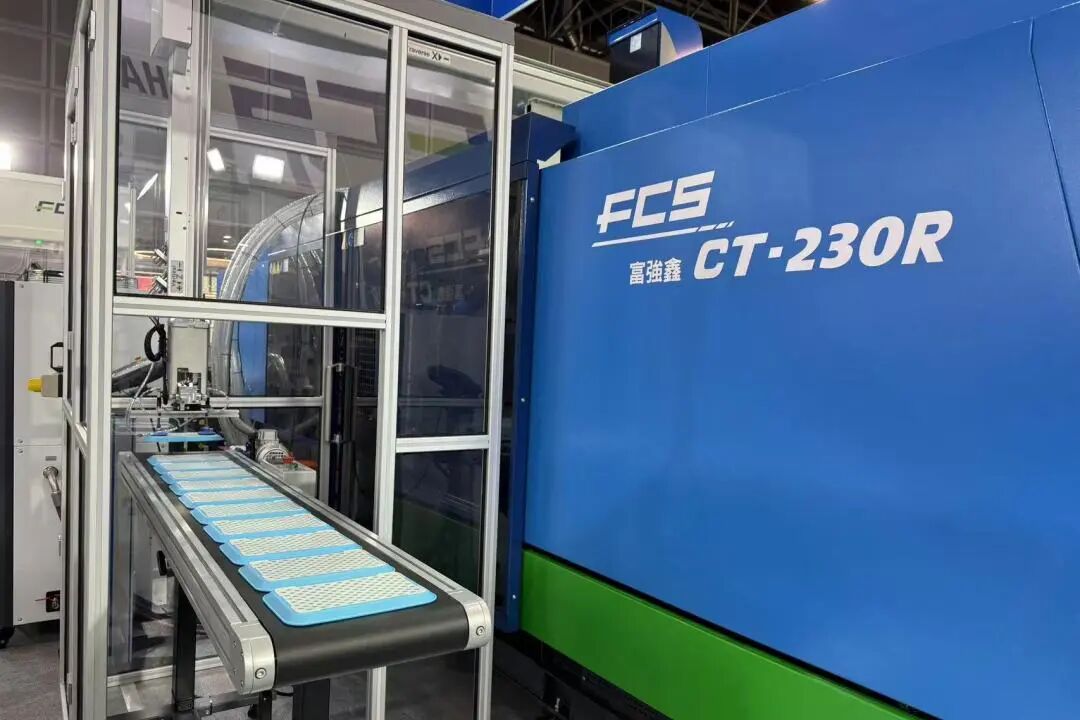

CT-230R | Dual-color synchronous × High-speed stability

The CT-230R is a fully electric two-color injection molding machine, equipped with a high-precision rotary table and two independent injection units. It is particularly suitable for high-end multi-material or multi-color applications, such as automotive interiors, power tools, and medical devices.

The exhibition will demonstrate the process of producing two-color household products, utilizing PP and TPE materials to achieve high-efficiency dual-material molding in a single cavity. Technical highlights include:

Positioning accuracy of the turntable is ±0.005°.

The servo drive rotation speed is increased by 30-50%, effectively shortening the molding cycle.

Linear guide rail injection unit, precisely controls back pressure and reduces the risk of material overflow.

High repeatability and stable forming capability, suitable for mass production of complex high-value parts.

In addition, the CT-230R is paired with FCS's independently developed.iMF 4.0 Intelligent Manufacturing SystemIt can achieve production monitoring, energy consumption tracking, predictive maintenance, and remote diagnostics, assisting users in enhancing overall equipment efficiency and quality consistency.

CT-120e | Precision Electric × Sustainable Application

Image/ CT-120e On-site Display of Glasses Injection Molding Solution

CT-120e is a newly launched compact all-electric injection molding machine by FCS, featuring high-speed injection and exceptional stability, specifically designed for clean and high-precision processes such as optical components, medical consumables, and environmentally friendly products.

At the exhibition site, this model will be paired with PA6+GF material recycled from marine waste fishing nets to produce eco-friendly eyeglass frames, showcasing the design and sustainable co-existence concept conveyed by the fishery-friendly circular eyewear molding system. This equipment features:

The injection speed can reach up to 300 mm/s, suitable for rapid filling.

Design without tie bars to reduce contamination risk, suitable for cleanroom applications.

Full servo closed-loop control system provides excellent molding accuracy and stability.

High-order injection curve control to ensure stable forming quality of regenerated materials.

The application of this loop forming fully reflectsFCS in "Sustainable Materials × Smart Devices"Innovative strength of integrated practice.

Intelligent Manufacturing × Sustainable Practices

In the global trend towards net-zero carbon emissions, FCS is actively promoting smart manufacturing and sustainable practices. Through the iMF 4.0 intelligent injection management system, it integrates sensing data, AI analysis, and cloud monitoring to comprehensively enhance energy efficiency, reduce carbon emissions, and achieve predictive maintenance.

By integrating MuCell® microcellular foaming technology, material usage and energy consumption can be effectively reduced while maintaining product strength and lightweight structure, achieving truly sustainable molding. The proactive application of recycled plastics further demonstrates FCS's tangible commitment to ESG promises, collaborating with material suppliers and brands to establish a co-creation mechanism for a circular economy, working together to create a low-carbon future.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track