200,000 tons of poe launched! clariant bets on halogen-free flame retardants! solvay, basf, and mitsubishi chemical introduce new materials

This week, the chemical new materials sector has seen frequent developments, with companies adjusting strategies and building capacity simultaneously: Daicel announced the integration of Polyplastics' engineering plastics division in April 2026 to enhance corporate value. Songwon plans to establish a wholly-owned OPS production base in Saudi Arabia to serve the Middle East market. Nouryon is increasing its investment in China, expanding catalyst production capacity, and planning to establish an innovation center. There have been significant advancements in capacity, with Dingjide's 200,000-ton POE project successfully commencing operations, marking its strategic transformation. The Huajin Aramco large-scale refining project has completed seven units simultaneously. LG Chem announced the closure of its HDPE plant in Korea to address industry challenges, while Dow's polyethylene facility in the United States is expected to restart this week. Meanwhile, Clariant's new flame retardant production line in Daya Bay will start operations next month, focusing on electric vehicle materials.

In terms of innovative materials, Sekisui Chemical has introduced a low-density, high-performance polyamide to reduce the weight of electronic devices. Mitsubishi Chemical has developed an anti-thrombogenic elastomer targeting the medical market. BASF and Zhenhai Refining & Chemical have respectively launched sustainable Nylon 6 and a high-temperature retortable polypropylene film. Cooperation on the application side of materials is active, with BASF collaborating with LEMON to develop new clothing materials, and Avient working with ReForm to promote the application of composite materials in the construction field. The Indian market has also seen the emergence of the first biodegradable billboard, highlighting the industry's ongoing exploration of sustainable development.

Company News

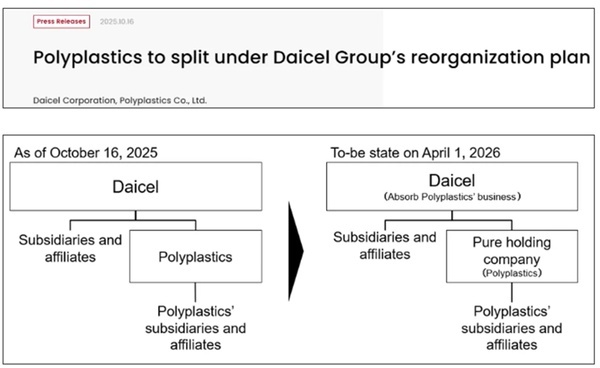

Daicel restructures Polyplastics to integrate the engineering plastics segment.

On October 16, 2025, Daicel Corporation (hereinafter referred to as Daicel) and its wholly-owned subsidiary Polyplastics Co., Ltd. (hereinafter referred to as Polyplastics) announced a group corporate restructuring plan, with the core content being the comprehensive integration of Polyplastics' engineering plastics segment. According to the officially disclosed information, this restructuring will adopt a spin-off and acquisition model, with a key timeline set for April 1, 2026. Daicel has clarified that the core goal of this engineering plastics segment integration is to maximize the corporate value of the group.

Songyuan fully invests in Saudi OPS.Production base

Songwon Industrial Co., Ltd. recently announced a significant new investment plan to establish a state-of-the-art One Pack System (OPS) production facility in the Kingdom of Saudi Arabia (KSA).

The new state-of-the-art production facility is planned to be completed in 2028 and will be wholly owned by Songwon Industries. It will primarily produce a range of Songnox brand One Pack Systems (OPS) products, which are high-performance additive compounds that facilitate efficient production of polyolefin resins. By expanding local production capacity and enhancing supply chain flexibility, this plant will help the company better serve the rapidly growing polyolefin market in the Middle East.

Nouryon makes several significant investments in China.

Recently, Nouryon announced several significant investments in China. At the Jiaxing production site, Nouryon has completed the capacity expansion of organometallics, doubling the production capacity of triethylaluminum. This product is a key co-catalyst for producing polyethylene and polypropylene, essential for packaging materials, automotive components, and consumer goods. By 2027, Nouryon plans to initiate the production of Modified Methylaluminoxane (MMAO) in China. This product is a crucial component of the catalyst needed for manufacturing polyolefin elastomers used in solar panels, another rapidly growing sector in China. Additionally, the company plans to establish an organic peroxide innovation center in Tianjin by 2026, further enhancing the application research and development capabilities for specialty polymers to accelerate product development and increase customer support.

New Zebang plans to invest in polyimide.

Recently, on the investor interaction platform, Capchem stated that it has completed the layout of fluorinated polyimide monomers and resins. This initiative by Capchem to incorporate fluorinated polyimide monomers and resins is an attempt to enter the high-end capacitor packaging materials market. It also completes the final step in the full industrial chain, forming an integrated capability from materials to components. Additionally, Capchem plans to develop polyimide film products for specific scenarios such as flexible electronic skin. It is reported that the company's current production capacity for perfluoropolyether products is 2,500 tons, and they are constructing the aforementioned 30,000-ton high-end fluorine fine chemicals project.

Join forces with Sinopec! Foshan Plastics Technology 34.69The Billion Nylon Film Project

On October 14th, FSPG Hi-tech Co., Ltd. held its fifth extraordinary general meeting of shareholders in 2025, where it reviewed and approved the proposal regarding the company's plan to establish a project company to invest in the construction of a polyamide-nylon film project. According to the announcement, FSPG Hi-tech Co., Ltd. will jointly establish a project company with Sinopec Hunan Oil and Petrochemical Co., Ltd. in Yueyang City, Hunan Province, to invest in the construction of the polyamide-nylon film project. The project company plans to have a registered capital of 960 million yuan, with FSPG Hi-tech Co., Ltd. contributing 576 million yuan for a 60% equity stake, and Hunan Petrochemical contributing 384 million yuan for a 40% equity stake.

Production Capacity Dynamics

Ding Ji De, POE

Liaoning Dingjide Petrochemical Co., Ltd.'s 200,000-ton/year POE (Polyolefin Elastomer) high-end new material project has reported another success. According to the progress announcement disclosed by Dingjide on the evening of October 16th, the project has recently been officially put into production and has successfully produced qualified POE products. Dingjide stated that the commissioning of the POE industrial facilities is a milestone in the company's strategic development, marking its growth from a producer of fine chemical additives and catalysts to a diversified manufacturer of new materials and fine chemicals.

7The installation was completed on the same day! Over 800.Billion Yuan Large Refining Project Construction Sprint

Recently, the Huajin Aramco Petrochemical and Raw Material Engineering Project has reached another milestone, with the simultaneous mechanical completion of seven refining units, including a 15 million tons/year atmospheric and vacuum distillation unit and a 4.2 million tons/year high-propylene catalytic cracking unit. This marks a decisive advancement in the construction of the core process units in the refining sector of the project, laying a solid foundation for subsequent feedstock trial runs.

LGChemicals will stop high-density polyethylene production in Daesan, South Korea.

LG Chem Ltd. announced plans to close its high-density polyethylene (HDPE) plant located in Daesan, South Korea, according to a customer letter seen by Platts, part of SP Global Commodity Insights, on October 14. While the company stated that more details of the timeline are still pending, the announcement follows persistently weak trading activity in Far East Asia. South Korea's petrochemical industry is currently facing severe profitability challenges, leading to structural adjustments and business redeployment across the industry, the company stated.

Dow in the United States will restart 5 this week.Number, 7Polyethylene unit, ignition point 6Device recovery pending

According to Dow's latest estimate last week, the Poly5 and Poly7 units used for polyethylene (PE) production at its Freeport, Texas plant are expected to restart this week after being shut down due to a fire on October 6. A spokesperson for the American chemical company stated that it is currently unclear when the Poly6 polyethylene unit, where the fire originated, will be able to resume production.

Guangxi Petrochemical 810,000 tonsStyrene-butadiene-styrene thermoplastic elastomer (SBSThe device was successfully started on the first attempt.

On October 12th, the 80,000-ton/year Styrene-Butadiene-Styrene (SBS) unit of the Guangxi Petrochemical Refining and Chemical Integration Transformation and Upgrade Project successfully produced qualified products, achieving a successful startup in one go. The SBS unit was constructed under an EPC contract by Huanqiu Xinjiang Company, with a consortium formed by Huanqiu Xinjiang Company and the First Construction Company of the Engineering Construction Company jointly executing the project. The unit utilizes the process technology jointly developed by Huanqiu Xinjiang Company and Dushanzi Petrochemical, which allows for the production of elastic, multi-grade products. Depending on the final use and product range, it can produce SBS products with different compositions and structures to meet the needs of downstream asphalt modification, polymer modification, shoe manufacturing, adhesives, and more. This is of great significance for enriching the variety of chemical products of Guangxi Petrochemical and enhancing market competitiveness.

Bohai Chemical: Subsidiary Bohai Petrochemical PDHDevice (6010,000 tons/The year will be in 10.Month 13Day shutdown for maintenance

Bohai Chemical (600800) announced on October 13 that it discloses the main operating data for the third quarter of 2025 of its wholly-owned subsidiary, Tianjin Bohai Petrochemical Co., Ltd. (referred to as Bohai Petrochemical), as follows: In the third quarter, the production of propylene was 133,800 tons, and the sales volume was 130,900 tons; the average price of propylene in the third quarter was 5,712.8 yuan/ton, a year-on-year decrease of 8.94%. On the same day, Bohai Chemical announced that according to the annual plan, Bohai Petrochemical's PDH unit (600,000 tons/year) will undergo a shutdown for maintenance starting from October 13, 2025, with the maintenance expected to last about 30 days.

Clariant's new flame retardant production line in Daya Bay will be operational in 2025.NovemberProduction starts monthly, focusing on electric vehicle materials.

Recently, the Swiss chemical company Clariant announced that the second production line at its flame retardant manufacturing facility in Daya Bay, Guangdong, China, is expected to officially commence operations in November 2025. This production line will primarily produce the new Exolit® OP flame retardant series aimed at the electric vehicle sector, in response to the growing demand for high-performance materials in the Asian market.

Focusing on Asia's first halogen-free flame retardant base

Clariant's Daya Bay site is its first halogen-free flame retardant factory built in Asia. In December 2021, the first production line officially commenced construction, completed after 18 months, and started operations in 2023, with a total investment of 60 million Swiss francs. The products cover multiple fields including electric vehicles, 5G communication, and energy transportation. The subsequent launch of the second production line involved an additional investment of 40 million Swiss francs, further expanding production capacity.

As of now, Clariant's total investment in the Daya Bay site has reached 180 million Swiss francs (approximately 1.35 billion RMB), becoming an important part of the company's strategic layout in China in recent years. Over the past five years, Clariant has invested a total of 300 million Swiss francs (approximately 2.25 billion RMB) in China, including the CATOFIN catalyst plant in Jiaxing and the integrated park in Shanghai's Xinzhuang area.

The production capacity of long-chain nylon and copolymers has doubled! NYCOAThe third special nylon reactor has been officially put into operation.

Leading engineering nylon resin manufacturer NYCOA of the United States announced that its headquarters production facility in Manchester, New Hampshire, has officially inaugurated its third specialty nylon reactor. This brand-new polymerization line is expected to double NYCOA's production capacity for long-chain nylon and copolymers.

Innovative Materials

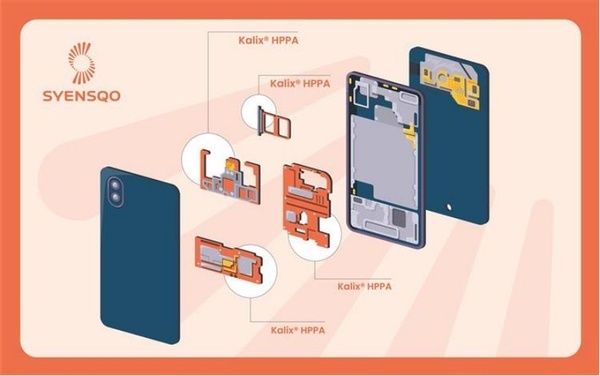

Shisuo launched a new low-density high-performance polyamide (HPPA)It can significantly reduce the weight of structural components in consumer electronic products.

Recently, Syensqo, a global leader in advanced materials and specialty chemicals, announced the launch of Kalix LD-4850 BK000, a new low-density high-performance polyamide (HPPA) designed to meet the ever-changing demands of the consumer electronics industry.

Mitsubishi Chemical Develops Anti-Thrombosis Elastomer Material

Recently, Mitsubishi Chemical Corporation (MCC) has launched a joint research project aimed at promoting the application of its antithrombotic thermoplastic elastomer Zelas AMP in medical devices. Mitsubishi Chemical stated that the core polymer of this material combines two structures: one is a hydrophilic structure that enhances blood compatibility, and the other is a hydrophobic structure that improves adhesion to the base resin. When added to materials such as polyvinyl chloride, polyurethane, or engineering plastics, it can impart antithrombotic properties, low protein adsorption, and reduce bacterial adhesion. Mitsubishi Chemical announced that the company plans to commercialize this material by 2027 and introduce it to the global market.

BASF launches Ultramid LowPCFAnd Ultramid BMBExpand sustainable nylon 6 in North America.Product Mix

BASF is expanding its sustainable nylon 6 product portfolio in the North American market by launching two innovative products: Ultramid LowPCF (lower product carbon footprint) and Ultramid BMB (biomass balance). These new solutions enable customers to reduce the carbon footprint of their products and achieve sustainability goals without sacrificing performance or altering existing production processes or supply chains. Both Ultramid LowPCF and Ultramid BMB use renewable natural gas (RNG) derived from organic waste as a raw material, and are traceable through a mass balance approach. While maintaining the excellent performance of Ultramid nylon 6, these products offer a lower carbon footprint compared to conventional grades.

Breakthrough in Technological Barriers! Zhenhai Refining & Chemical Successfully Develops and Produces New High-Temperature Cooking Film Polypropylene Product

Recently, Zhenhai Refining & Chemical successfully completed the first trial production of a newly self-developed high-temperature cooking film polypropylene product, yielding 346 tons of product that meets quality standards. High-temperature cooking film polypropylene is an advanced polymer material with excellent properties such as high-temperature resistance, tensile strength, and high mechanical strength. It can be widely used in the packaging of cooked foods, pet foods, and other food packaging fields. The product has high added value and a broad market application prospect.

Material Application

BASF and LEMONSign a Memorandum of Understanding to jointly develop new clothing material solutions.

BASF and LEMON Co., Ltd. have signed a memorandum of understanding to collaborate on promoting new apparel application solutions using Freeflex fibers made from BASF's Elastollan thermoplastic polyurethane (TPU). As a leading producer of functional nano membranes, LEMON plans to use Freeflex in the production of its waterproof and windproof clothing. The memorandum also outlines future collaboration opportunities in technology development and business expansion.

Avant and ReFormCollaboration to promote the application of composite material solutions in the construction field.

On October 15, Zhuansu Vision reported that Avient Corporation announced a successful collaboration with key customer ReForm. ReForm specializes in designing and manufacturing continuous fiber reinforced thermoplastic (CFRTP) composite solutions, which are cost-effective and adaptable for various applications in concrete infrastructure within the construction market.

ReForm utilizes its patented Continuous Forming Machine (CFM), a thermoplastic pultrusion technology, to process CFRTP laminates into continuous profiles. By integrating an online thermoforming process, CFM can achieve curved, complex shapes and multi-geometry designs, surpassing the limitations of traditional pultrusion technology, which typically can only produce straight profiles.

Leveraging these capabilities, ReForm is advancing the application of CFRTP, utilizing the material's lightweight and corrosion-resistant properties to support the next generation of concrete infrastructure.

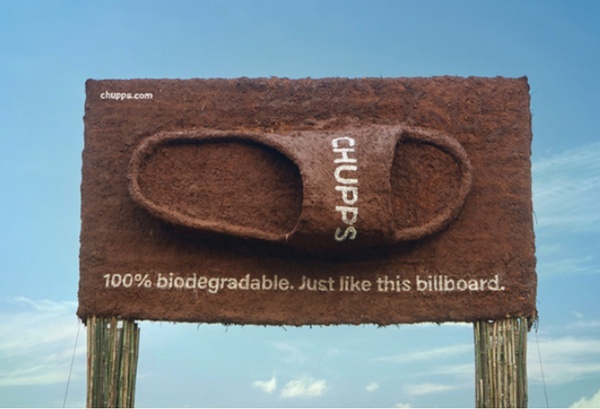

India launches first biodegradable billboard, promoting 100%Biodegradable slippers

Recently, Indian homegrown open footwear brand Chupps Footwear unveiled India's first biodegradable billboard in Bandra, Mumbai, marking a pioneering initiative in the field of sustainable fashion. Conceived by INTO Creative, this billboard symbolizes Chupps' bold commitment to reducing fashion waste, both in its products and promotional activities. The new billboard in Bandra, Mumbai, took four days to install and measures 20 feet by 10 feet. It is entirely made of biodegradable materials, using a massive bamboo structure instead of the common iron and tin structures, and employs a mixture of earth, clay, cow dung, hay, and sawdust to create the giant sliders and background. The title is written with fresh limestone instead of ordinary white paint.

Edited by: Lily

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track