Redefining Investment: When Injection Molding Machines Turn from Cost Centers into Value Assets

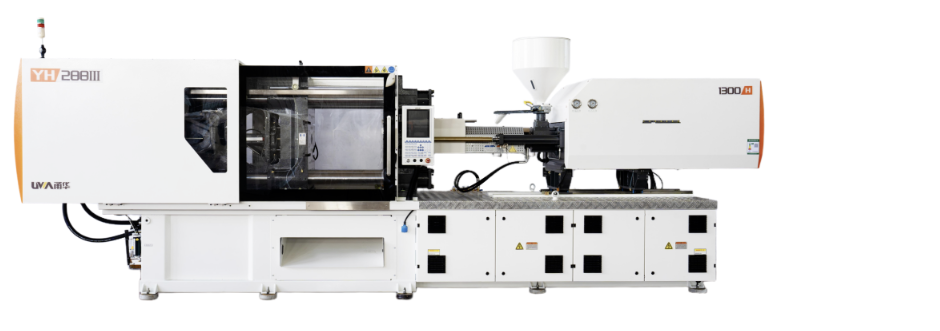

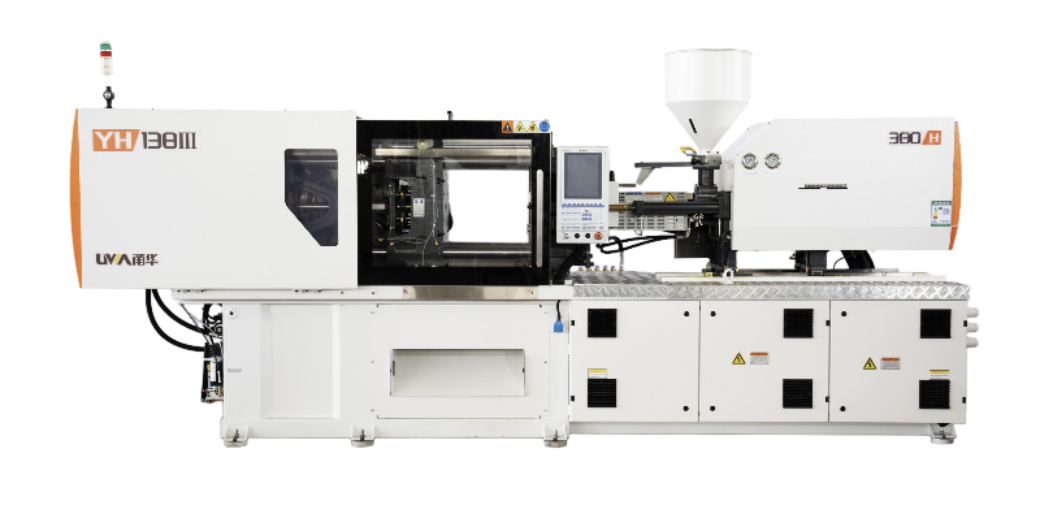

On the decision-making scale in manufacturing, equipment procurement is often simply categorized as a "cost." However, when you re-examine it through the lens of assets, an excellent injection molding machine carries far more than just the purchase price. It is a precision asset capable of continuously generating positive cash flow, a "production engine" that constantly appreciates on your company's balance sheet. Yonghua YHIII electric pre-plasticizing series is designed to reconstruct this value perception.

From "Cost Consumption" to "Value Output": A Financial Logic Transformation

From a traditional perspective, equipment is a vehicle for depreciation and a source of expenses. However, modern manufacturing management requires us to see deeper data: the real costs are hidden in inefficiency, fluctuation, and uncertainty.

Efficiency Cost: The Precise Conversion of Time into Money

The most direct value of equipment upgrades lies in the optimization of production cycle times and the compression of non-productive time. Higher response speeds and shorter molding cycles mean that more conforming products can be produced within the same asset depreciation period. This directly dilutes fixed costs per unit and enhances asset turnover efficiency.

Quality Costs: The Invisible Valve of Profit Loss

Defect rates are not just a waste of materials, but a multiple loss of productivity, energy consumption, and man-hours. A device capable of controlling quality fluctuations within a very narrow range effectively shuts off "profit leak valves" for you continuously. Improved stability brings predictable output and a controllable cost structure, which is the most valuable certainty in financial planning.

Energy Costs: An Underestimated Long-Term Cash Outflow

Energy consumption is not a fixed cost but a manageable variable closely linked to equipment efficiency. Advanced drive and control systems can significantly increase the ratio of energy converted into effective output, meaning each unit of electricity carries a higher value output. In the long run, this constitutes a continuous cost advantage and cash flow savings.

Maintenance Costs: Hidden Expenses and Operational Disruptions

Unplanned downtime and frequent maintenance incur more than just parts and labor costs; they trigger a chain of losses, including production interruptions, order delays, and delivery risks. High-reliability design and maintenance-free features are specifically engineered to reduce these difficult-to-quantify "operational interference costs," safeguarding the continuous value-creation capability of production assets.

YHIII Series: Redefining Asset Attributes

Taking the YHIII electric preplasticizing series as an example, we will analyze how it has transformed from a "production tool" into a "value-creating asset" through its robust technological core.

High-efficiency productive assets

Adopting a servo motor coupled with synchronous belt transmission or an integrated electric pre-plasticizing system, it achieves a 15%-40% increase in screw speed, improving quality while shortening the molding cycle. This translates to higher output per unit time and lower fixed cost allocation per piece, fundamentally enhancing asset turnover efficiency and return on investment.

Risk Mitigation Assets

Through mechanical design enhancements such as increased tie bar diameter and strengthened platen structure, the equipment's rigidity and fatigue resistance have been improved. The adoption of a low-inertia injection design and a high-response control computer achieves a clamping force repeatability of <0.5%, an injection accuracy of <0.3%, and a product quality repeatability of <0.2%. This significantly reduces quality risks and batch losses caused by equipment fluctuations or precision deviations, thereby protecting the company's reputation and customer trust.

Green compliant assets

All-electric preplasticizing technology fundamentally eliminates the risk of hydraulic oil leaks, and its low-noise characteristics improve the working environment. Actual measurements show that its energy consumption level is significantly lower than traditional solutions, which not only reduces ongoing operating expenses but also makes it a "forward-looking investment" for companies to cope with stricter environmental regulations in the future, avoiding potential environmental upgrade costs or production shutdown risks.

From a financial perspective, a shrewd equipment upgrade is essentially the conversion of working capital into productive assets that can continuously create a competitive advantage. It optimizes the economics of the entire manufacturing system, enhancing the company's overall return on investment and its ability to withstand risks.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

CBAM Officially Implemented In Its First Month: How Chinese Export Enterprises To Europe Complete Their First Compliance Declaration?

-

100% Recycled Plastic Bricks: A New Tool to Replace Traditional Concrete and Combat Floods

-

Vynova's UK Chlor-Alkali Business Enters Bankruptcy Administration!

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories