100% Recycled Plastic Bricks: A New Tool to Replace Traditional Concrete and Combat Floods

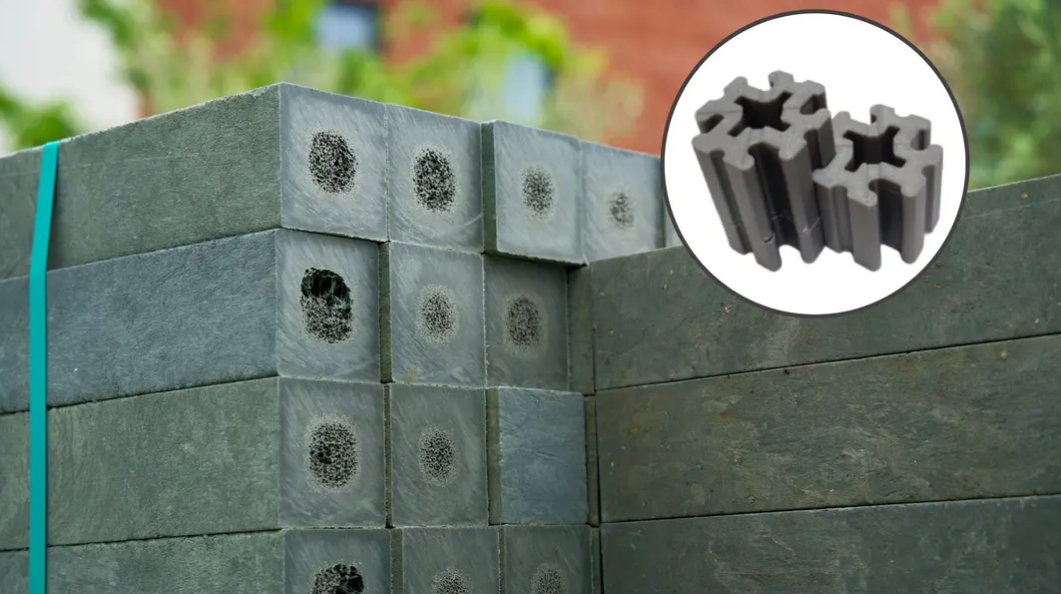

At CES 2026, WES-Tec Global showcased an innovative building technology called the ECOCCUBE system. This system aims to address plastic pollution and the various infrastructure risks posed by climate change by converting waste plastics into durable construction modules, particularly suitable for vulnerable environments prone to flooding. The goal is to provide a sustainable alternative to traditional concrete in certain civil engineering applications, while simultaneously tackling the issue of plastic waste on a large scale, addressing coastal erosion, flooding, and structural instability.

The core material of ECOCCUBE is 100% recycled waste plastic. WES-Tec Global employs a proprietary process called Newcycling, which is unique in that it retains the physical properties of the plastic while giving it a new structural purpose. Unlike traditional recycling systems, the Newcycling process does not require the sorting or cleaning of mixed plastic waste; specialized "Newcycling factories" can directly transform these waste plastics into construction-grade bricks.

A company spokesperson stated in an interview at CES: "Our technological advantage is significant, allowing us to recycle various types of waste plastics without the need for cumbersome sorting or cleaning steps." They also emphasized that the system converts plastic into civil engineering materials, rather than products for consumer use.

ECOCCUBE is designed for harsh environments, suitable for areas such as coastlines, rivers, and sloped terrains. These blocks made from recycled plastic can provide strong support for shoreline reinforcement and flood control infrastructure.

According to the company, ECOCCUBE exhibits outstanding mechanical properties, with a compressive strength of 26.4 MPa and a tensile strength of 16.7 MPa, which outperforms many traditional concrete applications. Moreover, due to its lighter weight, it can effectively reduce costs during transportation and installation. A company spokesperson noted, "These materials are primarily used in coastal and infrastructure sectors." It was also mentioned that preventing erosion, earthquakes, and tsunamis are key application scenarios for this material.

ECOCCUBE not only performs excellently in terms of performance but also brings measurable environmental benefits. According to life cycle assessment data, producing one kilogram of ECOCCUBE products can reduce carbon dioxide emissions by 2.99 kilograms, approximately 6.6 pounds. A 25-kilogram unit (about 55 pounds) can reduce carbon dioxide equivalents by 74.69 kilograms, equivalent to a reduction of 165 pounds of carbon dioxide emissions.

The system plays a significant role in environmental protection by effectively preventing plastic from being incinerated, landfilled, or leaked into ecosystems. Additionally, it meets the qualification requirements for carbon credits and carbon storage mechanisms.

WES-Tec Global has over ten years of extensive experience in the concrete and civil engineering fields, but its waste plastic recycling business has only recently developed. A company spokesperson stated, "This is our first time participating in CES," and revealed that the deployment work is still in the preparation stage.

Despite this, the innovative technology has gained widespread recognition. ECOCCUBE won an Honor at the 2026 CES Innovation Awards and a Silver Award at the 2025 Edison Awards.

Currently, WES-Tec Global is actively seeking partners to expand the scale of its technology deployment and promote its climate-centric building model globally, contributing more to addressing climate change and plastic pollution issues.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Middle East Tension Spikes Global Energy Pattern, Crude Oil and Plastic Industries Face Multiple Challenges

-

Middle East Tensions Escalate Sharply: How Polyolefins Respond Amid Soaring Risk Premium

-

Middle East Polymer Export Hub Hit in Sudden Attack, Global Supply Chain Sounds Alarm

-

[Forward-Looking Analysis] Impact of Escalating U.S.-Iran Tensions on Domestic Chemical Market

-

Futures Surge Violently, Polyolefin Spot Prices Rise Sharply in Tandem