PFAS Control Tightens! Asahi Kasei, Avient, Kingfa Technology and Others Break Through, Who Will Win the Trillion-Dollar Fluorine-Free Alternative Market

According to a report from foreign media on February 2nd by CPBJ, Asahi Kasei has developed a new PFAS-free polyamide (PA) engineering plastic, specifically designed for applications with stringent requirements for low-friction performance. For decades, the engineering plastics industry has relied on PFAS additives to achieve low friction and wear resistance.

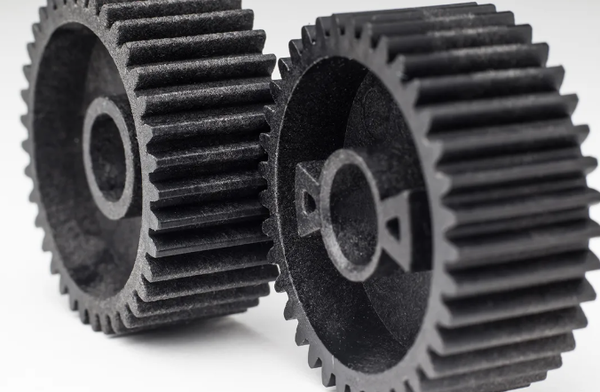

Asahi Kasei's new PFAS-free polyamide boasts excellent low-friction and sliding properties, crucial for applications where grease lubrication is not feasible. Its stable performance under high loads and high temperatures makes it an ideal choice for sliding mechanical parts like gears and chain guides that require stable operation in oil-free, dry environments.

As major global markets such as the EU and the US increasingly tighten regulations on per- and polyfluoroalkyl substances (PFAS), manufacturers across various industries are urgently seeking high-performance alternative materials. For example, France has banned cosmetics containing PFAS entirely from January 1, 2026, while the EU's Packaging and Packaging Waste Regulation sets an August 12, 2026, deadline for phasing out PFAS in food packaging.

So, why are countries tightening the use of PFAS materials? What mature alternative solutions have material manufacturers launched? Special Plastic World brings you a systematic review today.

01 Regulatory pressure intensifies, global PFAS restrictions upgraded

PFAS encompass over 8,000 different chemicals. Due to their exceptionally strong carbon-fluorine bonds, they possess significant chemical and thermal stability, leading to their widespread use in sectors such as textiles, coatings, electronics, and food packaging. However, this very stability makes them virtually non-degradable in the natural environment, earning them the moniker "forever chemicals."

The 2025-2026 period is set to become a critical juncture for global PFAS regulation. France has fired the first shot with a comprehensive PFAS ban, prohibiting the manufacturing, import, export, and sale of cosmetics containing PFAS from January 1, 2026.

The EU's Packaging and Packaging Waste Regulation, published in January 2025, explicitly restricts the use of PFAS in food packaging. California, Minnesota, Colorado, and other US states have also implemented or are about to implement bans on PFAS in cosmetics.

Against this backdrop, cross-border e-commerce platforms have responded swiftly to the trend. In December 2025, Temu added RSL-PFAS to its mandatory testing list for high-risk products, covering five major categories including children's products, food contact materials, and apparel. Any product descriptions containing keywords such as "waterproof," "oil-proof," or "stain-resistant" that fail to provide a qualified test report will face platform-wide removal.

As the world's largest manufacturer and consumer of fluorochemicals, China has been rapidly catching up in PFAS regulation, despite a relatively late start. The "List of Key Controlled New Pollutants," implemented in 2023, has already included several key PFAS substances such as PFOA, PFOS, and PFHxS under control. Furthermore, Sichuan Province issued the country's first local standard setting emission limits for per- and polyfluoroalkyl substances in chemical industrial parks, effective July 2025.

02 Tide is seizing the fluorine-free track! Chinese and foreign material giants reveal alternative solutions

Facing increasing global regulatory pressure, materials companies have accelerated the research and commercialization of PFAS-free solutions in recent years.

As mentioned at the beginning of the article.

Asahi KaseiLEONA™ PFAS Free wear-resistant series is a polyamide resin developed with proprietary technology, offering sliding performance comparable to added fluororesins without the inclusion of PFAS. This material exhibits excellent sliding properties even in non-greased environments, making it suitable for applications requiring lubricity and as a replacement for materials subject to regulations against PTFE.

January, materials solutions innovation enterpriseEvonik Corporation

Avient Corporation)Announcing the addition of GlideTech™ specialty formulated materials to its portfolio of engineering materials for the healthcare sector. Available in a variety of standard base resin grades and customizable to meet specific customer needs, GlideTech materials are single-pellet polymer composites that simplify production processes while delivering exceptional coefficient of friction (CoF) performance without the use of polytetrafluoroethylene (PTFE). Additional benefits of GlideTech formulated materials include: compliance with ISO 10993-5 and USP <87> biocompatibility standards, compatibility with common sterilization methods, and improved processing performance on conventional extrusion equipment compared to traditional catheter materials.

Image source: Evonik

Previously, Evante had announced the launch of its product in Latin America. Containing antioxidantsAOHaiFu™ ( ) PFAS-free Processing aidsThis liquid processing aid offers a fluorine-free solution for regional film packaging producers and is manufactured without intentionally added per- and polyfluoroalkyl substances (PFAS). Extending Avient's established non-PFAS processing aid technology, this product adds antioxidant functionality and is suitable for polyethylene (PE) and polypropylene (PP) processing.

Source: Evant

1Month, Mitsubishi Chemical CorporationWe have successfully developed an innovative technology that imparts excellent gas barrier and oil resistance to paper-based substrates by coating them with our proprietary SoarnoL™ ethylene-vinyl alcohol copolymer (EVOH) resin solution. This technology aims to replace PFAS (per- and polyfluorofluoroalkyl substances) traditionally used to improve the oil resistance of paper packaging. Tests show that its oil resistance is superior to traditional PFAS-based packaging materials, even under high temperatures or folding conditions. SoarnoL™ material meets stringent hygiene standards for direct food contact and is suitable for packaging fried chicken, hamburgers, and other foods, effectively extending food shelf life and reducing waste. This development provides a high-performance and environmentally friendly PFAS alternative solution for the food packaging industry amid increasingly stringent global regulations.

Image source: Mitsubishi Chemical

Star PlasticsIn January 2026, the company announced the launch of a new line of PFAS-free polycarbonate composite materials, part of its Orion engineering resin product series. These products comply with Underwriters Laboratories 94 flame retardancy ratings V0, V2, and HB, and are suitable for various industries including consumer electronics, electrical, and home appliances.

Clariant The new AddWorks PPA product line was launched in June 2025, representing a new generation of PFAS-free polymer processing aids designed specifically for polyolefin extrusion applications. These innovative formulations are completely free of per- and polyfluoroalkyl substances, as well as inorganic, silicone, or polysiloxane materials. They significantly improve processing performance, including enhanced extrusion efficiency and elimination of shark skin defects.

At CHINAPLAS 2025 in May, more companies showcased PFAS-free solutions.

Golden Hair TechnologyAnnounced the world's first PFAS-free ultra-thin flame-retardant high-performance polycarbonate material achieving UL94 V-0 flame retardancy at a thickness of 0.8mm.

Polyrocks ChemicalIntroducing a high-performance, PFAS-free flame retardant PC material that achieves UL94 V0 rating at an ultra-thin 1.5mm thickness.

LG An EV charging station housing was showcased, utilizing LG Chem's engineering plastic product LUPOY ER5001PN. This material boasts a PCR content of 50% derived from mechanical recycling, and it contains PFAS-free flame-retardant PC/ABS, having achieved UL94 flame retardancy testing V-0 rating certification. Furthermore, it reduces carbon emissions by approximately 50% compared to virgin materials.

Introducing a series of PFAS-free flame retardant materials, such as PFAS-free FRPC and PFAS-free FRPC/ABS, both capable of achieving UL94 @V0 flame retardant ratings (1.6mm~3.0mm). These materials also offer extensive color design freedom and excellent processing performance.

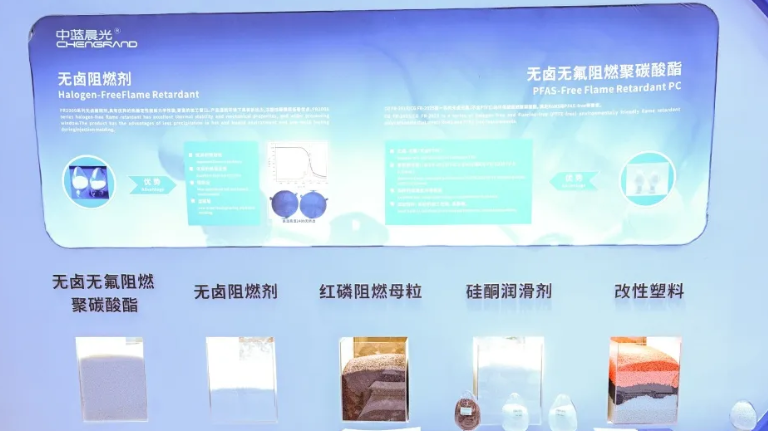

ChemChina Sunrise The CGPR-2015 and CG FR-2025 are two PFAS-free flame retardant PC materials, achieving breakthroughs in environmental protection and high performance. This series of products adopts a halogen-free and fluorine-free formula (PTFE-free), passes UL94 V0 flame retardant certification, appears as white opaque pellets, and combines excellent processing performance with environmental attributes.

Source: CHINAPLAS

Polyplastics Daicel Focusing on technological breakthroughs and innovative solutions in the field of sustainable development, it is currently developing products that comply with environmental regulations related to per- and polyfluoroalkyl substances (PFAS). PFASHalogen-free flame retardant PBT 。

Samyang Group A series of PFAS-free PC materials on display, including transparent PC films, sound insulation boards, and lampshades, can be applied to toaster casings, inductor coil casings, coffee machines, charger casings, and more.

AomeikaiIntroducing EcoLube™, a new eco-friendly brand offering PFAS-free engineered plastic solutions. This series achieves excellent lubricity and long-lasting durability through innovative technology, significantly reducing environmental impact. It can replace PTFE in materials such as PP, PC, PPS, and PEEK.

……

From food packaging to textiles, from water treatment to fire-fighting equipment, PFAS-free solutions are rapidly replacing traditional materials in various fields.

Three Major Challenges and Breakthrough Paths for PFAS-Free Alternatives

Despite significant progress in the development of PFAS-free alternative materials, the industry still faces multiple challenges in a complete transition.

Performance Matching...is a major challenge. Compared to hydrocarbon structures, fluorocarbon structures possess a larger surface area and hydrodynamic volume, making them more effective in reducing surface tension. The minimum surface energy of CF3/CF2 groups renders fluorochemicals both hydrophobic and oleophobic. Therefore, developing non-fluorinated alternatives that can fully match these properties requires continuous technical innovation.

Cost pressure Cannot be ignored either. Compared to traditional PFAS-containing materials, many new alternative materials have higher production costs, which may affect market acceptance. However, as regulations tighten and production scales expand, the cost gap is expected to gradually narrow.

Technical Adaptabilityis also a major challenge. Different application scenarios have different material performance requirements, and a single alternative solution cannot meet all needs. For example, Asahi Kasei's LEONA™ PFAS Free series addresses this challenge through different formulation designs, such as a wide range of filler additions to achieve different strength levels, and a wide range of raw polymers for heat and water resistance.

In the future, PFAS replacement technologies will develop in a more diversified and efficient direction.Multi-technology convergencewill become important trends, such as combining plasma technology with silicone polymers to develop new coating materials that are both environmentally friendly and have excellent performance.

Bio-based materialsThey also demonstrate broad prospects. Bio-based materials such as bio-wax emulsions and cellulose fatty acid esters are continuously improving in terms of enhancing water resistance and vapor permeability, providing viable PFAS alternatives for industries such as food packaging.

IV. The PFAS-free Era Has Arrived: New Opportunities Emerge in Material Substitution?

As the global regulatory network tightens, PFAS... The alternative market is rapidly forming and trending towards diversification and high performance. This includes companies like Kingfa Science & Technology and LG. Chemical, Huasu, and other companies have successively joined the ranks of alternative product research and development. The product range has expanded from flame-retardant PC. 、PC/ABSAlloys, extended to multiple core categories such as polyamide resins, polymer processing aids, food packaging coatings, and special lubricant formulations.

In the coming years, as the performance of alternative materials is validated and continuously optimized, and their application scale expands, costs are expected to gradually decrease, further accelerating the pace of PFAS-free transition.

Source: Compiled by Zhuan Su Shi Jie, Chinaplas, Baijiahao, Packaging Manager, etc.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Goldhair Technology Stock Soars, Operating Quality Gradually Improves