Multi-Billion Euro Deal! Shortly After Divesting Interior and Exterior Business, Forvia Hella Secures Major Sensor Contract! Impact Analysis on the Plastics Industry

On December 20th, Zhuansu Shijie observed and discovered that Forya Haile received major good news, successfully securing a mass production order for high-resolution radar sensors from a global high-end manufacturer, with the order amounting to several hundred million euros. The research and development work for this order is being conducted at the headquarters in Lippstadt, Germany, and production is expected to officially commence in Europe by mid-2028.

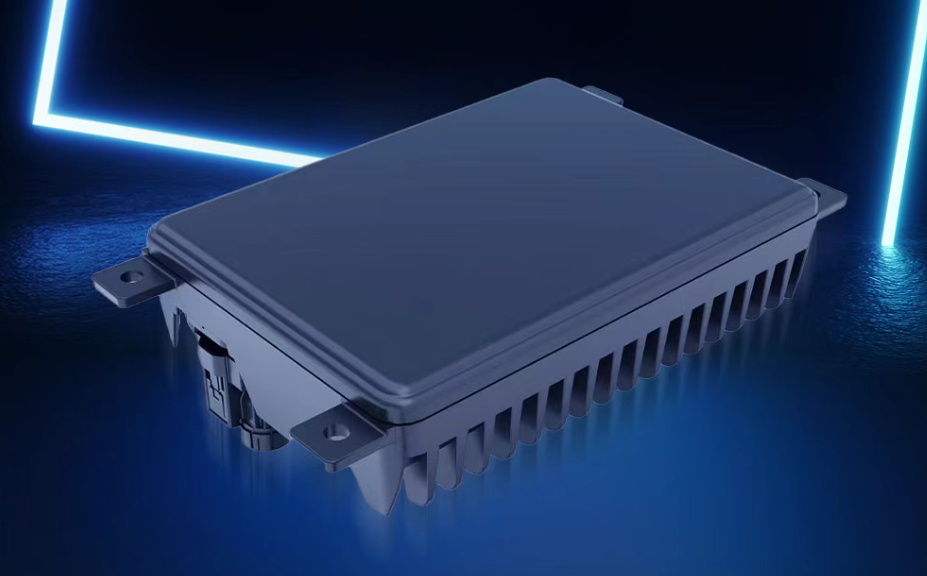

High-resolution radar (HRR) is a core technology for SAE Level 2+ and Level 3 intelligent assisted driving, with extremely stringent requirements for sensor performance. The ForWave7HD high-resolution radar sensor launched by Freyia Hella demonstrates exceptional performance, featuring high resolution and a multi-channel design. It can be flexibly configured with up to 32 transmit and 32 receive channels, with an improved angular resolution of less than 1°, allowing for clear differentiation of individuals in very close proximity within dense vehicles or crowds. Leveraging advanced antenna and chip technology, its detection range can reach 400 meters, providing a wider field of view and superior near-range detection performance. Additionally, the product is built on a modular and scalable platform, enabling flexible adaptation to different vehicle requirements.

Freyia Haila has been deploying sensors for a long time.

The ForWave7 radar family from Fureya Haila is rich in products. In addition to the ForWave7HD, there is also the cost-optimized ForWave7e, which received an order from a leading automotive supplier in Asia this summer. Additionally, there are two other series with different cost-performance ratios, as well as radar products specifically designed for trucks, fully meeting the diversified needs of the market.

Source: Freya Hella

Freya Hella's development history started with entering the market through 24GHz rearview radar, followed by the mass production of 77GHz radar. Their products can be deployed at the four corners of a vehicle, covering scenarios such as lane change assistance or intersection assistance systems. They can also be installed at the front center of the vehicle, in the radiator grille area, or behind brand logos. This fall, Freya Hella achieved the milestone of producing its 100 millionth radar sensor. The mass production order for the ForWave7HD marks the company's transition from a leading supplier in the front-rear radar field to a full-range supplier. The General Manager of Freya Hella's Electronics Division stated that this order consolidates the company's market position as a full-range radar supplier, promotes the adoption of advanced driver assistance systems, accelerates the development of autonomous driving technology, and will further accelerate the growth of the radar business, a core growth engine, through this cooperation.

What plastic materials are used in sensors?

In the automotive sensor field, plastic materials play a crucial role. Taking millimeter wave radar as an example, its protective cover needs to simultaneously meet requirements such as weather resistance, dimensional stability, and electromagnetic compatibility. Many companies are actively researching and innovating in this area. Toray Industries from Japan has developed polyimide (PI) materials suitable for 5G and millimeter wave radar, which feature both heat resistance and low dielectric loss characteristics. SABIC has launched the LNP series of thermoplastics, achieving radar wave penetration and lightweight design through glass fiber modification. Polyplastics has developed conductive-grade PBT materials, which provide electromagnetic shielding and cost optimization functions.

In addition, polymer-derived SiCN ceramics have attracted attention in the field of electromagnetic wave absorption due to their advantages such as light weight and low thermal expansion coefficient. Significant achievements have been made in enhancing wave absorption performance through multi-component synergistic effects, such as the wave absorption performance of nano-ceramics like SiHfCN-C, SiHfCN-B, and SiHfCN-N being significantly improved.

The former has just divested its interior and exterior business.

At the same time, FORVIA has issued a statement regarding the asset divestment process. The group has been conducting a comprehensive strategic review of its business portfolio and, based on the review results, has officially initiated the sale process of certain businesses, with assets related to the automotive interior business segment being a key focus for divestment. This move is not impulsive; in the increasingly competitive automotive industry and complex and rapidly changing market environment, it is a necessary choice for businesses to optimize their structure and concentrate resources on developing core businesses to enhance competitiveness. FORVIA aims to seize the opportunity for industry transformation and achieve sustainable development.

Freya's automotive interior business unit holds a significant position in the automotive industry, providing complete dashboard, door panel, and center console systems for vehicles. In modern automobile manufacturing, plastic injection molded parts are widely and critically applied to these components. The dashboard housing often employs injection molding technology, with polycarbonate (PC) being a common material due to its excellent transparency and mechanical properties. This provides outstanding protection and visual effects for the dashboard, ensuring the driver can clearly read information while protecting internal electronic components during accidents. Components such as the central console, armrest box, and door interior panels also extensively use injection molding processes. Acrylonitrile-butadiene-styrene (ABS) copolymer is a common material used for its good toughness and corrosion resistance, capable of withstanding daily friction and impact to maintain the interior's clean and aesthetic appearance.

In the third quarter of 2025, Faurecia's interior business division achieved sales of 1.09 billion euros, accounting for nearly 18% of the group's revenue. Julien Thomas, an analyst at TP ICAP Midcap, stated that automotive interiors are Faurecia's premium asset, with a consolidated market position ranking among the top three globally, demonstrating competitiveness and high credibility. The overall value could reach 3.5 billion euros, which may help Faurecia address its debt issues.

Nowadays, major automotive parts giants are increasingly divesting low value-added businesses. For example, Faurecia-Hella has divested its automotive interior business to focus on high-end radar sensor business, serving as a typical example. For the plastics industry, it must follow this trend towards high-end development in the future in order to remain competitive in the intense market and jointly promote the high-quality development of the automotive industry and related supporting industries.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

Mexico officially imposes tariffs on 1,400 chinese products, with rates up to 50%

-

Nissan Cuts Production of New Leaf EV in Half Due to Battery Shortage