Conquering nylon's water absorption problem: A Full-Chain Dimensional Stability Solution from Material Modification to Process

A meticulously crafted nylon gear, perfect in the lab, jammed after less than a month of installation due to a 0.5% "swelling," the culprit being an inherent characteristic of nylon material itself. Water absorption 。

Dimensional changes in nylon products in humid environments are a common challenge in the industry. The polar amide groups in nylon molecular chains readily bind to water molecules, leading to water absorption and swelling of the material. 。

For common nylons like PA6 and PA66, the saturated water absorption can reach over 2.5%, causing dimensional changes that may exceed 0.6%-1.0%, which is catastrophic for precision components.

01 Water absorption root

The essence of nylon's water absorption stems from its chemical structure. The regularly arranged amide bonds on the molecular chain are strong polar groups that can form strong hydrogen bonds with water molecules. This characteristic gives nylon excellent toughness and abrasion resistance, but also brings about the fatal weakness of dimensional instability.

Water absorption depends not only on the type of nylon, but also on crystallinity, ambient temperature and humidity, and the thickness of the product. Moisture initially penetrates the amorphous regions, leading to volume expansion, which in turn triggers internal stress rearrangement and a decline in mechanical properties.

02 Start with the recipe

Reducing water absorption fundamentally lies in modifying the material itself, which is akin to cultivating "internal strength" to solve the problem. Enhanced modification is one of the most direct and effective methods. Adding 30% glass fiber can reduce the water absorption of PA6 by about 50%-70%. The addition of fibers not only reduces the relative content of water-absorbing groups, but also creates a physical barrier inside the material that blocks the penetration of water molecules. Carbon fiber is more effective, but more expensive.

Blend modification offers another approach. To blend nylon with low water absorption polymers (such as PP, PE), compatibilizers like maleic anhydride grafted polymers are required to improve interfacial adhesion. This method can adjust water absorption within a certain range, but attention should be paid to potential losses in other properties.

Material selection itself is a strategy. Considering low-moisture absorption nylon grades like PA12, PA610, or PA46 from the outset of a project can mitigate issues at the source. PA12's water absorption rate is only about 1.5%, significantly lower than PA6's 2.7%, and while more expensive, it's often a worthwhile investment for precision applications.

03 Injection Molding Process Control

Even with a good material formulation, improper injection molding processes can negate the benefits, which is why "process control" is essential for ensuring dimensional stability.

-

Raw material drying is the primary and most easily overlooked step. Nylon raw materials must be thoroughly dried, typically at 120°C for 4-6 hours, to reduce moisture content to less than 0.1%. Using a dehumidifying dryer and ensuring the hopper is well-sealed can prevent the dried raw materials from reabsorbing moisture.

-

Careful adjustment of molds and process parameters is equally crucial. Raising the mold temperature (PA6 is recommended at 80-120℃) can reduce the cooling rate and decrease internal stress and deformation caused by uneven shrinkage.

-

Extend the holding time and appropriately increase the holding pressure. Helps to maximize packing, reduce sink marks, and minimize dimensional deviations.

-

Gate design optimization should not be overlooked. Using multiple gates or fan gates can balance melt flow and prevent localized shrinkage and warpage caused by long flow paths or unbalanced filling.

04 Post-processing and Environmental Control

Post-mold treatment is the "last line of defense" to ensure long-term dimensional stability of products, serving as "quality reinforcement" before product delivery. Annealing effectively eliminates residual stress inside the product. Treating the product in an oven at 120-150℃ (below the material's melting point) for 1-4 hours allows molecular chains to rearrange, releases internal stress, and reduces the risk of deformation during subsequent use.

-

Hygroscopic preconditioning is a method of actively balancing dimensions. By soaking the finished products in 80°C water for 2-4 hours or placing them in a controlled humidity environment, they can reach a moisture absorption equilibrium state in advance. This will significantly reduce dimensional changes of the products in actual use, making them particularly suitable for applications requiring extremely high dimensional stability.

-

Surface coating technology provides a physical barrier for nylon products. Spraying or immersing the product in silane, fluorocarbon coatings, or nano-hydrophobic coatings (contact angle >120°) can form a dense hydrophobic layer on the surface, effectively blocking moisture penetration. This method has minimal impact on the original performance of the product and is suitable for applications such as appearance parts and electronic enclosures.

-

Environmental control in storage and packaging is equally important. Finished products should be stored in a humidity-controlled environment with RH<50%. High-precision parts are recommended to be stored in moisture-proof packaging (such as aluminum foil bags with desiccant).

-

For long-term storage of precision parts, it is even possible to... Consider incorporating a built-in desiccant (such as molecular sieves). To continuously absorb moisture from the environment.

05 The Art of Balancing Cost and Performance

In practical engineering applications, different solutions need to strike an optimal balance between cost and performance.

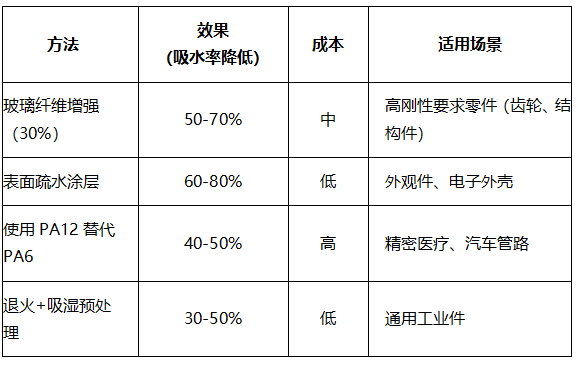

The comparison table below clearly shows... Cost-effectiveness and applicable scenarios of various methods. :

For most industrial applications, glass fiber reinforcement combined with annealing offers the best cost-performance ratio. However, for consumer electronics with high aesthetic requirements, a hydrophobic coating might be a more suitable choice.

For precision tubing in the medical and automotive fields, it is worth investing in low water absorption nylon materials such as PA12.

06 Verification and Testing Standards

After implementing any improvement plan, its effectiveness must be verified through standardized testing. Water absorption testing should be conducted according to ISO 62 (24 hours immersion in water at 23°C), which is the most fundamental method for evaluating the water absorption of materials.

Dimensional stability assessment requires measuring the linear expansion rate before and after water absorption. For PA6, this value is typically within... 0.6%-1.0%The effective improvement measures should be able to control this variation within a smaller range.

The retention rate of mechanical properties is a key indicator for assessing the impact of water absorption, typically requiring that the tensile strength decrease by no more than 20% after water absorption. This test comprehensively evaluates the reliability of materials in humid environments.

By systematically combining application methods, the impact of water absorption on nylon products can be minimized to meet the most stringent precision injection molding requirements. The key is to deeply understand material properties, choose solutions accordingly, and find the optimal balance between cost and performance. 。

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

Multifaceted Collaboration: PA Prices Rebound Against Trend to Break Through

-

European Supermarket Shelves Full of "Misleading" Recycled Plastic Packaging Claims