Asahi kasei bids farewell to pfas with new low-friction fluorine-free polyamide engineering plastic

As global regulatory policies on per- and polyfluoroalkyl substances (PFAS) continue to tighten in the EU and the US, manufacturers across various industries are urgently seeking high-performance alternative materials. This is to meet increasingly stringent environmental and safety standards while ensuring that the core technical performance of their products remains uncompromised. To meet this market demand, Asahi Kasei has developed a new PFAS-free polyamide (PA) engineering plastic, specifically designed for applications with strict requirements for low friction performance.

For decades, the engineering plastics industry has relied on PFAS additives to achieve low friction and wear resistance. With increasing regulatory pressure, many industries such as automotive and industrial machinery are now seeking alternatives. Asahi Kasei's new PFAS-free polyamide precisely addresses this transitional need by combining environmental friendliness with the high-end material performance required for next-generation components.

Stable and reliable performance

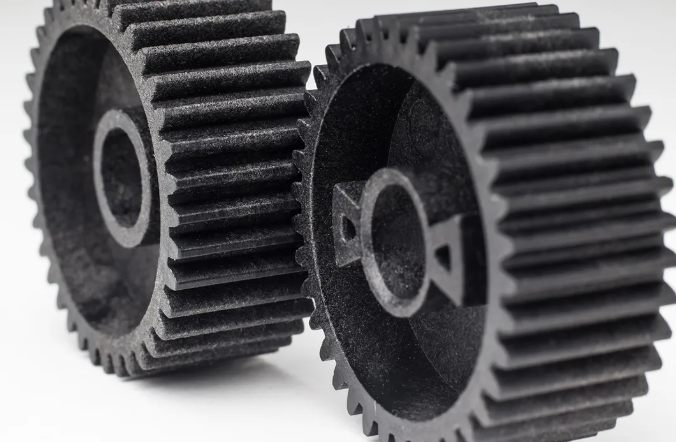

This new polyamide features excellent low-friction and sliding properties, which are crucial for applications where grease lubrication is not feasible. Meanwhile, the material maintains stable performance under high-load and high-temperature conditions, making it an ideal choice for sliding mechanical components such as gears and chain guides that require stable operation in oil-free, dry environments.

Available in both standard and enhanced versions

To meet the diverse needs of global manufacturers, Asahi Kasei offers PFAS-free polyamide in both unreinforced and reinforced grades, allowing engineers to flexibly choose the optimal material solution that combines strength, stiffness, and durability based on specific application scenarios.

Leveraging its proprietary processing control technology developed in-house, Asahi Kasei can customize material properties by optimizing filler content, heat resistance, stiffness, and wet-state performance, offering customers high design flexibility and facilitating a smooth transition to PFAS-free material solutions without sacrificing product performance.

Yoshitaka Hori, Senior General Manager of Asahi Kasei's Leona PA66 business, stated: "As global industries progressively phase out PFAS, market demand for new materials is no longer limited to compliance but extends to higher requirements for improved product durability and usage efficiency. The new PFAS-free polyamide we are launching is precisely designed to meet this demand. We also look forward to supporting our customers in creating safer, more sustainable products with this material."

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Goldhair Technology Stock Soars, Operating Quality Gradually Improves