Xiamen Geogrid Co., Ltd.-Welcome

Quality Products ● Exploration and Discovery in [Quality Selection]: Geogrid [Content 152, 6987, 4999 QQ 578888971], Geogrid Company, Geogrid Quotation, Geogrid Specifications, various models of Geogrid are available.

High-Quality Engineering—UsingLianyi Brand,20 years focused on high quality

Who can solve“Lianyi” product customers’ six major concerns?

1. Can the construction period be guaranteed?

Lianyi has an internationally advanced production base, covering a total area of 1000 acres, making Lianyi a large geotechnical material production base, with an annual production capacity of 500 million. Annual exports of 10 million USD.

2. Can quality be guaranteed?

The equipment and management system ensure product quality.

Lianyi has introduced more than 10 advanced German production devices, making it the smallest automatic production line in the country; all products are sampled and tested upon leaving the warehouse to meet customer satisfaction.

3. Is the brand influence significant?

“Lianyi” is one of 11 manufacturers of geotechnical materials in the country; you tell me if its reputation is significant.

4. Is the delivery timely?

“Lianyi” has three major logistics bases to ensure timely, fast, and efficient service.

5. Is there a price advantage?

Lianyi Engineering Materials Co., Ltd. is a large-scale manufacturer of various geogrids in China; for all customers purchasing materials, we can provide free door-to-door delivery service.

Xiamen Geogrid has a full range of models and quality assurance.

Can be used safely for 50 years or more, easy to construct, and the effect is excellent! A large number of Xiamen geogrids are being distributed nationwide……

Xiamen Geogrid Co., Ltd.-Welcome

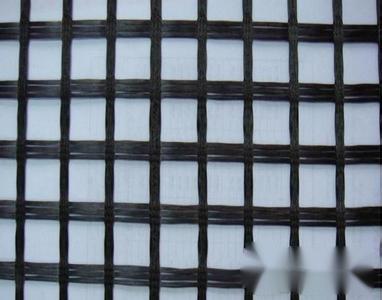

15269874999 Bidirectional Plastic Geogrid

Lianyi brand is trustworthy, a century-old brand, "to do medicine, one must first be a good person; to refine medicine, one must first refine the heart"; focusing on quality education is the source of promoting product quality. Quality is in the heart, product name is in the hand, responsibility is on the shoulder, and integrity is in the words and actions. Quality is the foundation of the brand, quality reflects quality, and quality guarantees the market. Conquer people's hearts with quality, let quality yield benefits, and operation is key. Complete the work well, with meticulousness as the standard. Cultivate a first-class team with first-class management, strive for first-class quality, and achieve first-class benefits. Build a backbone with integrity, create brilliance with quality; without quality today, there will be no sales tomorrow!

Leading enterprise in the industry 【1-5-2 6-9-8-7 4-9-9-9】 is now launching“Promotional Mode”“Low prices every day”, a different special sale company name:Lianyi Engineering Materials Co., Ltd.【Selected Quality Products,Qianjiang Geogrid Manufacturer-Qianjiang Geogrid Unit Price】 Main products: Foshan Fiberglass Geogrid|Foshan Steel-Plastic Geogrid|Foshan Plastic Geogrid|Foshan Crack-Resistant Tape, etc.

Product delivery standards:

The technical level of the products we provide is advanced, the quality is excellent, and they comply with current national quality standards or mutually agreed quality standards, ensuring that the products are brand new and unused. We guarantee that the products have satisfactory performance under correct installation and usage conditions. We will strictly adhere to the agreement to ensure quality and deliver products to you safely and on time.

The price of geogrids mainly depends on the choice of raw materials; the general service life of geogrids is over twenty years.

Due to users' lack of understanding of the product, it is easy to fall into the price trap, thinking that the lower the price, the better. Often neglecting product quality, which can lead to losses during use.

Misconceptions when purchasing fiberglass geogrids:

1. Selection misconceptions; geogrids are not just any product. As a type of corrosion-resistant material, different models of geogrids have different qualities and must be selected according to different usage environments and construction requirements. It is advisable to communicate with the manufacturer and choose carefully.

2. Price misconceptions; when we purchase items, we always think that the lower the price, the better the deal. Little do we know that the one who suffers is ourselves, as the items purchased cannot be used.

Lianyi Engineering Materials has established a credit mechanism through innovative efforts, accumulating trust, and relying on trust to close deals. Over the years, with the trust and help of both new and old customers, we have grown from the initial 2 geogrid devices to now having22 geogrid devices. This is due to the trust our customers place in us. We deeply realize that the future is a competition of credit and quality; those with better credit will be more successful, and those with better quality will also be more successful. We are willing to unconditionally return and compensate for all substandard products while protecting consumer rights. We adhere to the principles of integrity, transparency, and openness, being honest and doing practical work. Product quality is our life! Without product quality, we will lose the life of development. “We will never allow a single unqualified product to reach our users” is our commitment to our customers. In the same industry, we

never seek to be the biggest, but we work diligently to be the best. We warmly welcome friends from home and abroad, as well as industry peers, to communicate and cooperate with us. We will become friends with you with the unique enthusiasm of Hebei people.

Foshan > Geogrid Co., Ltd. welcomes you

The geotechnical materials produced by the company have the characteristics of wide width, high strength, long service life, corrosion resistance, and aging resistance, and are mainly used in water conservancy, railways, tunnels, landfills, artificial lakes, and other infrastructure projects, used in key national projects; all have received unanimous praise from users and experts.

Has won a good market reputation and made positive contributions to the construction of key national and local projects.

Bidirectional Stretch Geogrid is a high-strength reinforced geosynthetic material made from polypropylene (PP) as raw material, through plastic extrusion, sheet hole punching, longitudinal stretching, and transverse stretching. It has many advantages such as high strength, stable structure, aging resistance, and corrosion resistance.

Application fields: Bidirectional stretch geogrids are mainly used for reinforcement in soft soil engineering such as highways, railways, and for slope protection and large landfill projects, significantly enhancing the load-bearing capacity of soft soil foundations, preventing surface cracking and collapse, facilitating construction, and reducing maintenance costs.

Bidirectional plastic geogrid specifications include: The strength of fiberglass geogrids is (30kN-120kN), the strength of polyester geogrids is (30kN-300kN), the models of steel-plastic geogrids are (30-150kN), the strength of bidirectional plastic geogrids is (15kN-50kN), and the strength of unidirectional plastic geogrids is (35kN-300kN).

The width of geogrids: The maximum width of fiberglass geogrids, steel-plastic geogrids, polyester geogrids, and bidirectional plastic geogrids is 6 meters. The roll length of fiberglass geogrids is100 meters, the roll length of steel-plastic geogrids is50 meters, and the roll length of polyester geogrids is100 meters. The bidirectional plastic geogrids are100 meters and50 meters per roll. The width of unidirectional plastic geogrids is 3 meters. The roll length is50 meters.

Xiamen Geogrid Co., Ltd.-Welcome

15269874999 Bidirectional Plastic Geogrid

1. Bidirectional Plastic Geogrid

Unidirectional stretch geogrid is a high-strength geosynthetic material made from high polymer as the main raw material, adding certain UV-resistant and anti-aging additives, and stretching unidirectionally, which rearranges the originally dispersed chain molecules into a linear state. It is extruded into thin sheets and then punched into a regular mesh, followed by longitudinal stretching to form a high-strength geosynthetic material. This process makes the polymer oriented in a linear state and forms a uniform distribution with high joint strength in a long elliptical mesh structure. This structure has a high tensile strength and tensile modulus, with tensile strength reaching 100-200 MPa, close to that of low carbon steel, greatly outperforming traditional or existing reinforcement materials. Particularly, this product has an ultra-international-level high early (elongation rate of 2%-5%) tensile strength and tensile modulus, providing an ideal force-bearing and diffusion link system for the soil. This product has high tensile strength (>150 MPa), is suitable for various soils, and is currently a widely used reinforcement material. Its main features are: high tensile strength, good creep performance, easy construction, and low cost.

The unidirectional geogrid is made from high polymer (PP or HDPE), extruded into thin sheets and then punched into a regular mesh, followed by longitudinal stretching. This process makes the polymer oriented in a linear state and forms a uniform distribution with high joint strength in a long elliptical mesh structure.

Unidirectional stretch geogrid is a high-strength geosynthetic material.

Main uses

1. Unidirectional geogrid for reinforcing weak foundations: Geogrids can quickly improve the bearing capacity of foundations and control the development of settlement. The lateral confinement effect on the road base can effectively distribute the load over a wider sub-base, thus reducing the thickness of the base layer, lowering project costs, shortening construction periods, and extending service life.

2. Unidirectional geogrid for reinforcing asphalt or cement pavements: Geogrids laid at the bottom of asphalt or cement layers can reduce rut depth, extend the fatigue life of the pavement, and also reduce the thickness of asphalt or cement pavement to save costs.

3. Unidirectional geogrid for reinforcing embankments and retaining walls: Traditional embankments, especially high embankments, often require overfilling, and the edges of the embankments are difficult to compact, leading to risks of slope collapse and instability due to rainwater infiltration. Additionally, a gentler slope is required, taking up more land. Retaining walls have similar issues. Using geogrids to reinforce the slopes of embankments or retaining walls can reduce land occupation by 20-50%, extend service life, and lower costs.

4. Unidirectional geogrid for reinforcing river and sea dikes: It can be made into gabions and used in conjunction with geogrids to prevent dikes from being washed away by seawater, causing collapse. Gabions have permeability, which can mitigate wave impact and extend the life of the dike, saving manpower and resources, and shortening construction time.

5. Unidirectional geogrid for landfill management: Geogrids combined with other soil synthetic materials for landfill management can effectively solve uneven settlement and gas emission issues, greatly enhancing the landfill's storage capacity.

6. Special uses of unidirectional geogrids: Low-temperature resistance. After 200 cycles of repeated cold and hot at -45℃ to -50℃, all performance indicators meet requirements and have been tested on the Qinghai-Tibet Railway, making them suitable for the less frost-prone soils in the north, soils rich in frost, and poorly conditioned frozen soils.

Construction methods

○ When used for foundations and pavements, the construction method is the same as that for bidirectional geogrids.

○ When used for reinforcing soil retaining walls, the construction method is as follows:

1. Set the foundation and construct according to the designed wall system. When using prefabricated reinforced concrete panels, they are generally 12-15 cm thick, supported on prefabricated concrete foundations. The width should not exceed 30 cm, thickness not less than 20 cm, and buried depth not less than 60 cm to prevent frost heave from affecting the foundation.

2. Level the wall base, excavate and level according to design requirements. Soft soil must be compacted or replaced, compacted to the required density, extending slightly beyond the wall area.

3. Place the reinforcement materials; the main strength direction of the materials should be perpendicular to the wall and fixed with pins.

4. Fill the wall with earth using machinery; the distance between the wheels and the reinforcement materials should be at least 15 cm. After compaction, the thickness of one layer of soil should be about 20-15 cm.

5. During wall construction, the wall surface should be wrapped in geotextile to prevent soil loss.

Bidirectional geogrid is made from polyethylene or polypropylene through the processes of extrusion, sheet formation, and punching, followed by longitudinal and transverse stretching.

Welded plastic geogrid

Bidirectional welded geogrid is a new type of eco-friendly building material that enhances the reinforcement of polyethylene and polypropylene stretch bands with reinforcing fibers and then welds them into a “#” structure, which can be divided into single and double-sided adhesive or welded geogrids. This product has the advantages of high strength, minimal deformation, corrosion resistance, long service life, and ease of construction, meeting the usage requirements for various engineering projects for over 100 years.

2. Unidirectional plastic geogrid

Unidirectional plastic geogrid is made from polyethylene, extruded into thin sheets and then punched into a regular mesh, followed by longitudinal stretching. This process makes the polymer oriented in a linear state and forms a uniform distribution with high joint strength in a long elliptical mesh structure.

Uses:

● River dikes, lake embankments, tailings dams, sewage dams and storage areas, channels, and liquid storage pools (pits, ponds)

● Subways, basements, and tunnels, seepage-proof linings.

● Foundation and other saline seepage prevention. Geogrid specifications

● Horizontal seepage-proof cover in front of dikes and dams, vertical seepage-proof layers for foundations, construction cofferdams, waste sites.

● Saltwater and freshwater aquaculture.

● Roadbed for highways, railways; waterproof layers for expansive soils and collapsible loess.

● Roof seepage-proofing.

3. Knitted polyester geogrid

Knitted polyester geogrid uses high-strength polyester fiber as raw material. It employs a knitted directional structure, where the warp and weft yarns in the fabric are in a straight state, and the intersection points are bound together with high-strength fiber filaments, forming strong bonding points, fully utilizing its mechanical properties. High-strength polyester knitted geogrid has high tensile strength, low elongation, strong tear resistance, minor differences in longitudinal and transverse strength, UV aging resistance, wear resistance, corrosion resistance, lightweight, and strong interlocking ability with soil or gravel, playing a significant role in enhancing soil shear resistance and reinforcing the overall integrity and load-bearing capacity of the soil.

4. Steel-plastic composite geogrid

Steel-plastic geogrid is made from high-strength steel wire, treated specially, and combined with PE, with other additives added, extruded into a composite high-strength anti-tensile strip, with a rough textured surface, forming a high-strength reinforcing geogrid. From this single strip, a certain spacing is created through longitudinal and transverse weaving or layering, using special reinforced adhesive welding technology to weld the joints, forming a reinforced geogrid.

Fiberglass Geogrid

5. Fiberglass geogrid is made from fiberglass using a certain weaving process to form a mesh structure material. To protect the fiberglass and improve overall performance, it is treated with a special coating process to create a highway reinforcement material.

Grass grid base construction

Many residential communities have green belts connecting the roads, with lawns generally paved to the roadside. Due to poor management, the soil in many green spaces becomes severely compacted. The emergence of grass grids solves this problem perfectly. Grass grids are also widely used in fire lanes and parking lots, addressing the issues of increasing green areas and improving the ecological environment and safety. Below are some analyses of grass grid construction and maintenance experiences for peer exchange and reference.

The main components of grass grid bases are as follows:

1. Raw soil compacting + gravel + gravel + grass grid + mixed nutrient soil

2. Raw soil compacting + gravel + concrete foundation + gravel + grass grid + mixed nutrient soil

3. Raw soil compacting + gravel + concrete foundation + gravel + non-woven fabric + grass grid + mixed nutrient soil

From the analysis of construction cases, we draw the following conclusions: The first solution allows for good drainage, but over time, due to surface load, the ground is prone to collapse; the second solution is susceptible to nutrient soil loss due to rainwater erosion over time. Through technical discussions and combining experiences with vertical greening, we advocate for the third solution, adding a non-woven fabric layer, which can prevent nutrient soil loss and also retain water.

1. Feature introduction: 1. Complete greening: Grass grids provide over 95% grassed area, achieving a full greening effect, capable of sound absorption and dust collection, significantly enhancing the quality and taste of the environment. (Reference: Concrete grass bricks only have 30% voids)

2. Cost-saving: Grass grids combine parking and greening functions; in land-scarce urban areas, they save valuable space for developers.

3. Flatness: The unique and stable flat interlocking design of grass grids creates a flat overall surface, avoiding local depressions and making construction extremely convenient. (Reference: Concrete grass bricks are independent, requiring a concrete base to maintain flatness)

4. High strength, long life: Grass grids use patented special materials, with a compression capacity of over 200 tons/square meter, greater than the standard requirement for fire-fighting access of 32 tons/square meter.

5. Stability: UV resistance, acid-base corrosion resistance, wear resistance, and weather resistance from -40℃ to 90℃. (Reference: Concrete grass bricks are prone to cracking and damage due to temperature changes and frost)

6. Excellent drainage: The gravel load-bearing layer provides good drainage, facilitating the discharge of excess precipitation.

7. Protecting lawns: The gravel load-bearing layer provides some water retention, beneficial for grass growth, allowing grass roots to grow into the gravel layer. (Reference: Concrete grass bricks only have very small spaces, and in summer, temperatures can exceed 50 degrees)

8. Green and environmentally friendly: Grass grids are safe, stable, recyclable, and pollution-free, fully protecting lawns.

9. Lightweight: Grass grids weigh only 5 kg per square meter, extremely lightweight, quick to install, saving labor and shortening construction time. (Reference: Concrete grass bricks weigh 250 kg per square meter)

2. Construction features: 1. Eco-friendly, non-toxic, pollution-free, impact-resistant, aging-resistant, UV-resistant

2. Wear-resistant, corrosion-resistant, flame-retardant, strong greening function

3. Reduces surface reflection, reduces surface heat radiation

4. Reduces sound wave transmission, lowers noise pollution

5. Reduces dust, purifies air

6. Rainwater naturally seeps, soil does not wash away, no pooling

7. Water, air, and fertilizer circulate naturally, soil does not compact

8. Increases greening area; simple construction, lightweight

9. Freely combinable and removable, reusable

10. Excellent load-bearing capacity: can withstand over 200T/square meter weight

3. Base treatment for parking area grass grids:

1. The foundation soil should be compacted in layers, achieving a compaction rate of over 85%; for soft plastic or fluid plastic silt layers, it is recommended to fill with block stones and compact to densify.

2. Set a 150 mm thick sand and stone cushion layer. The specific approach is: 10% coarse sand, 60% crushed stone with a particle size of 20-40, and 30% clay mixed evenly, leveled, and compacted.

3. Set a 60 mm thick stabilization layer (also serves as a planting layer). The stabilization layer should consist of 25% crushed stone with a particle size of 10-30, 15% medium coarse river sand, and 60% cultivated soil mixed with an appropriate amount of organic fertilizer, all thoroughly mixed, spread on the sand and stone cushion layer, and compacted to serve as the base for the grass grid.

4. Spread a small amount of organic fertilizer on the base layer, and manually lay the grass grids. The shape dimensions of the grass grids are designed according to the size modulus of the parking space, generally not requiring cutting; when the parking space has special shape requirements or sewage manhole covers are present, the grass grids can be cut to fit the different shape requirements of the parking space.

5. Spread planting soil in the recessed planting grooves of the grass grids and sweep evenly into the grid holes, with the soil layer height set to be 5-10 mm below the surface of the grass grid.

6. Lay sod or sow grass seeds on top of the planting soil layer. When laying sod, it should be pressed firmly onto the planting soil. Water and maintain until the grass takes root before allowing parking.

For grass grids used in fire lanes:

1. When laying grass grids on fire lanes, the compaction of the foundation soil should meet the design requirements for general concrete fire lanes.

2. The gravel cushion layer and stone powder stabilization layer for fire lanes should also meet the design requirements for ordinary concrete fire lanes.

3. On the stone powder stabilization layer, create an 80 mm thick planting soil layer. The soil layer should consist of 30% crushed stone with a particle size of 10-30, 15% medium coarse river sand, and 55% cultivated soil mixed with an appropriate amount of organic fertilizer, all thoroughly mixed, spread on the compacted stone powder stabilization layer, and compacted to serve as the base for the grass grid.

4. Install and plant grass grids on the grass grid base.

5. It is worth noting that if the fire lane serves as the main pathway for vehicles due to frequent use and high speed, this can adversely affect the use of grass grids and the normal growth of grass, thus impacting greening and aesthetics. In this case, we recommend that the main vehicle traffic roads continue to use concrete surfaces, while grass grids should only be used in emergency situations for fire vehicles. Similarly, it is advisable to use concrete surfaces for the main roadways in parking lots, while grass grids can be used for green parking spaces.

For sidewalks using grass grids:

1. The original foundation must be compacted.

2. Lay grass grids on the compacted soil surface.

3. Spread planting soil in the recessed planting grooves of the grass grids and sweep evenly into the grid holes, with the soil layer height set to be 5-10 mm below the surface of the grass grid.

4. Lay sod on top of the grass grid. When laying sod, it should be pressed firmly onto the planting soil. Water and maintain until the grass takes root before use.

4. Construction precautions: 1. The gravel foundation must be compacted, considering the significant bearing pressure, with a smooth surface and a drainage slope of 1%-2% preferred. Water drainage holes in concrete foundations must be filled with pebbles or gravel and sand to prevent soil loss.

2. Each grass grid has interlocking features; when installing, they should be locked together. Once installation is complete, use a small roller or plate vibrator to compact the surface of the grass grids, making adjustments as needed until the surface is level.

3. It is recommended to use nutrient soil to fill the grass grids. When backfilling, water should be applied to allow the soil to settle, and a bamboo broom should be used to sweep the nutrient soil evenly into the grass grid holes, with the soil layer height set to be 5-10 mm below the surface of the grass grid.

4. The sod used is generally Manila grass, which is durable and easy to grow. When laying sod, leave about a 20 mm gap, staggering the layout in a checkerboard pattern. After laying the sod, water thoroughly to soften it, then use a small roller or plate vibrator to press the grass roots into the grass grids (repeating several times) to promote downward growth.

5. Allow a month of maintenance before parking; if installed between November and March of the following year (dormant period), the grass should be maintained for two months before parking.

6. During usage or after the rainy season, if a small amount of planting soil is lost, it can be evenly spread from the surface of the lawn to fill the soil washed away by rainwater.

7. The lawn requires 4-6 trims per year, timely weeding, fertilizing, and regular watering or installation of automatic sprinkler systems for necessary maintenance.

Xiamen Geogrid Co., Ltd.-Welcome 15269874999

Contact Manager Gao: 15269874999

Xiamen Geogrid Co., Ltd.≠Welcome to appreciate