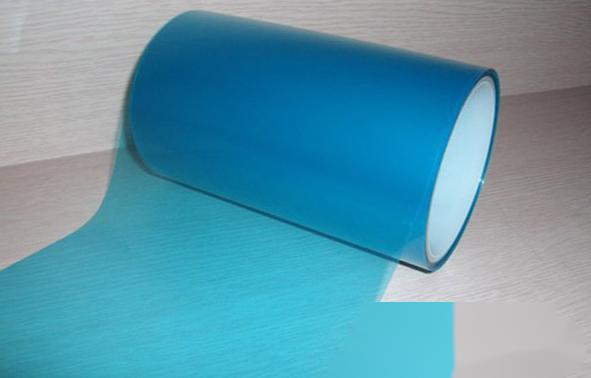

PET Release Film Product Introduction

PET release film is a commonly used material in thermal transfer printing, with PET as the substrate and coated with silicone oil, hence also known as silicone oil film. The conventional thickness ranges from 25um to 150um. There are distinctions between hot and cold peel, as well as glossy and matte surfaces. After undergoing antistatic and scratch-resistant treatment, the product exhibits excellent adhesion and conformity.

The PET release film is made from polyethylene terephthalate (PET) as the substrate, with a release material coated on the surface in the range of 0.2um-0.6um. The film surface is smooth and flat, with uniform coating, free from wrinkles, tears, particles, bubbles, pinholes, and other defects. This product features excellent physical and mechanical properties, small thickness tolerance, high transparency, low thermal shrinkage, and good flexibility.

PET release film is now widely used in various industries, including packaging, printing, circuit boards, laser anti-counterfeiting, lamination, electronics, sealing material films, reflective materials, waterproof materials, pharmaceuticals (plaster paper), sanitary paper, adhesive products, die-cutting, and punching processing.