The synthesis methods of PCTFE include bulk polymerization, solution polymerization, and dispersion polymerization, using peroxides as initiators to prepare by free radical polymerization.

PCTFE has excellent chemical stability, insulation, and weather resistance, and can be used for a long time at -196~125℃. Mechanical strength and hardness are better than polytetrafluoroethylene, and when made into films, it has good transparency and low gas permeability rate.

PCTFE is suitable for applications in contact with strong corrosive media, sealing and gasket materials in high-pressure systems, transparent materials for observation windows, and electrical insulation materials. Therefore, it has special significance in the chemical and atomic energy industries, but it is more expensive than polytetrafluoroethylene. Low molecular weight PCTFE has high density, excellent viscosity-temperature characteristics, and chemical corrosion resistance, and can be used as sealing liquid for highly corrosive media, lubricating grease, and balance liquid for navigation gyroscopes.

PCTFE has excellent rigidity, low temperature resistance, and cold flow resistance, and is an ideal sealing material under low temperature and high pressure conditions, with special applications in high-tech fields.

Applications:

1. Sealing and gasket materials for contact with strong corrosive media and high-pressure systems, transparent materials for observation windows, etc.

2. Electrical insulation materials, etc.

3. Low molecular weight PCTFE is used as sealing liquid for highly corrosive media, lubricating grease, and balance liquid for navigation gyroscopes, etc.

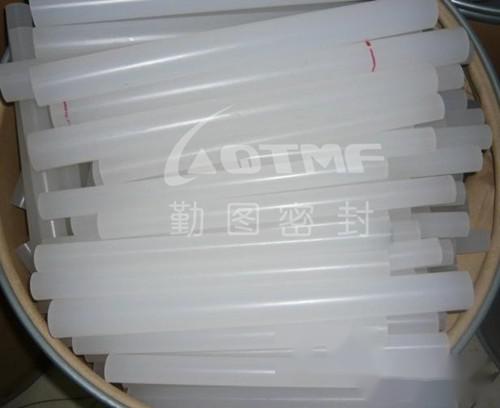

Our company has a variety of specifications of PCTFE rods, tubes, plates, sealing gaskets, washers, valve seats, etc. Specific specifications refer to PTFE product specifications (PCTFE products comply with relevant corporate standards).

PCTFE Products Item Unit Value

Density g/cm3 2.10-2.18

Tensile strength MPa ≥ 30

Elongation at break % ≥20

Continuous use high temperature ℃ -200-150

Dielectric strength Kv/mm ≥ 15