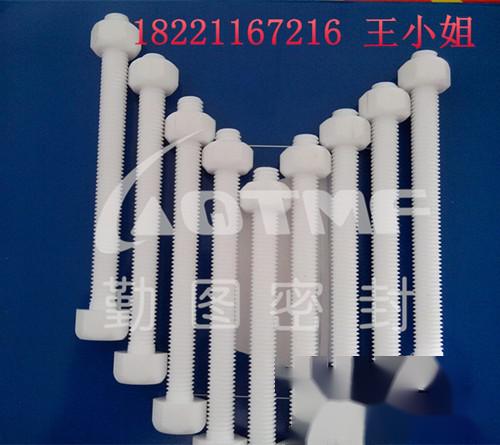

PTFE Screw

Polytetrafluoroethylene (PTFE), commonly known as 'plastic king'. The Chinese product names include "Teflon", "Teflon", "Teflon", and "Thflon". It possesses excellent chemical stability, corrosion resistance, sealing properties, high lubrication non-stick properties, electrical insulation, and good aging resistance.

PTFE is a synthetic polymer material in which all hydrogen atoms in polyethylene are replaced by fluorine. This material features resistance to acids and bases and various organic solvents, being almost insoluble in all solvents. Additionally, PTFE has high-temperature resistance and a very low coefficient of friction, making it not only a lubricant but also an ideal coating for non-stick pans and the inner layers of pipes.

Advantages of Use

1. High-temperature resistance - working temperature up to 250°C.

2. Low-temperature resistance - exhibits good mechanical toughness; maintains a 5% elongation rate even at -196°C.

3. Corrosion resistance - shows inertness to most chemicals and solvents, resistant to strong acids and bases, water, and various organic solvents.

4. Weather resistance - has a long aging life among plastics.

5. High lubrication - has one of the lowest coefficients of friction among solid materials.

6. Non-stick - has low surface tension among solid materials, does not adhere to any substances.

7. Non-toxic - physiologically inert, can be implanted in the body as artificial blood vessels and organs without adverse reactions.

Chemical Properties

1. Atmospheric aging resistance: radiation resistance and low permeability; maintains surface and performance unchanged after long exposure to the atmosphere.

2. Non-flammability: oxygen index below 90.

3. Acid and alkali resistance: insoluble in strong acids, strong bases, and organic solvents (including magic acid, which is fluoroantimonic acid).

4. Oxidation resistance: can withstand corrosion from strong oxidizers.

5. Neutrality: pH neutral.

Physical Properties

Density: 2.1–2.3 g/cm³

PTFE has relatively soft mechanical properties and very low surface energy.

PTFE exhibits a series of excellent performance characteristics: high-temperature resistance - long-term use temperature of 200 to 260 degrees; low-temperature resistance - remains flexible at -100 degrees; corrosion resistance - can withstand aqua regia and all organic solvents; weather resistance - aging life among plastics; high lubrication - has a low friction coefficient (0.04) among plastics; non-stick - has low surface tension among solid materials, does not adhere to any substances; non-toxic - physiologically inert; excellent electrical performance, making it an ideal Class C insulating material, capable of blocking 1500V high voltage with a layer as thick as newspaper; smoother than ice.

Mechanical Properties

Its coefficient of friction is extremely low, only 1/5 that of polyethylene, which is an important characteristic of perfluorocarbon surfaces. Additionally, due to the extremely low intermolecular forces between fluorocarbon chains, PTFE exhibits non-stick properties.

PTFE maintains excellent mechanical properties over a wide temperature range of -196 to 260°C, with one of the characteristics of perfluorocarbon polymers being that they do not become brittle at low temperatures.

Chemical Resistance and Weather Resistance

Except for molten alkali metals, PTFE is resistant to almost all chemical reagents. For example, when boiled in concentrated nitric acid or even aqua regia, its weight and properties remain unchanged, and it is nearly insoluble in all solvents, only slightly soluble in fully saturated alkanes above 300°C (approximately 0.1g/100g). PTFE does not absorb moisture, is non-flammable, and is extremely stable against oxygen and ultraviolet light, giving it excellent weather resistance.

Our company specializes in the production of high-strength PTFE screws, bolts, studs, high-temperature and high-pressure PTFE fasteners, low-temperature and high-pressure PTFE fasteners.

(National standard (GB); Industry standard (SH, HG, H, JB, GD); American standard (ANSI/ASTM); German standard (DIN))

Specifications: M3—M36

Products are widely used in industries such as petroleum, petrochemicals, thermal power, machinery, military, nuclear power, papermaking, coal mining, etc. Competitive prices, timely delivery, welcome to inquire, bulk orders preferred!!