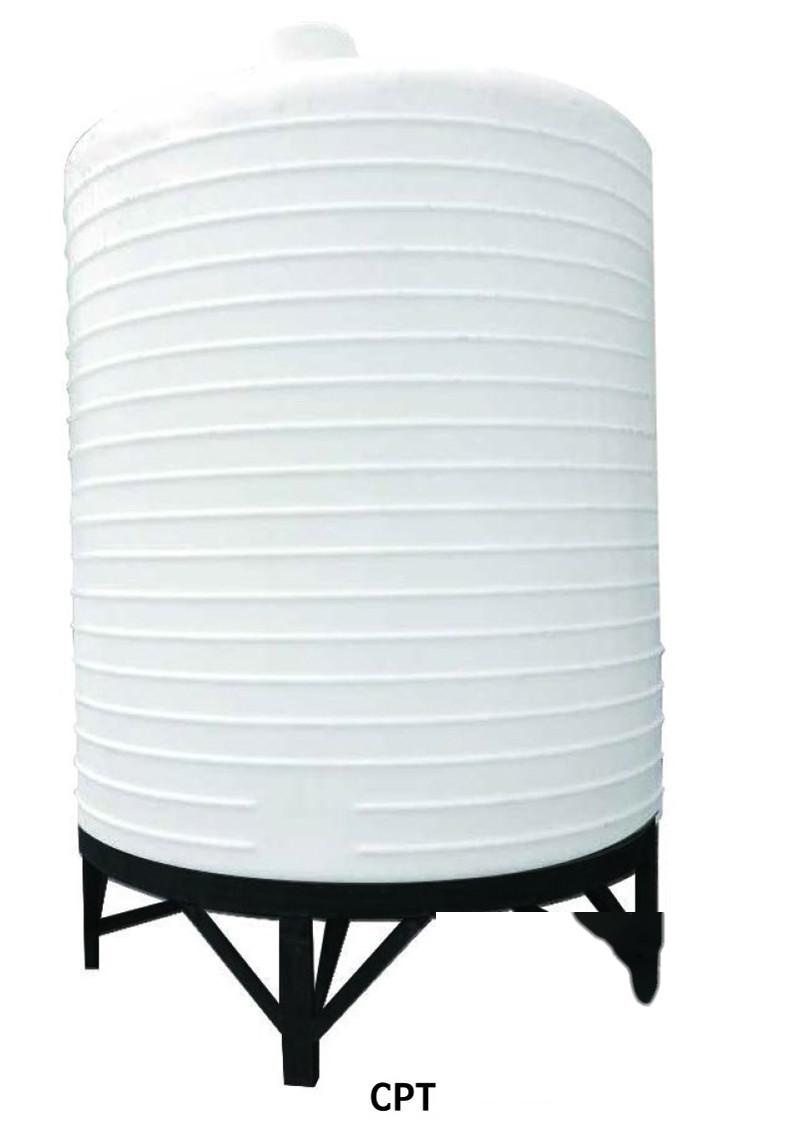

Cone Bottom Water Tank - CPT-250L

Cone Bottom Vertical Cylindrical PE Water Tank

|

|

|

Cone Bottom Vertical Cylindrical PE Water Tank Parameter Table!

Cone bottom water tank specification table: Class A products are for indoor storage, Class B products are for outdoor storage, and special class products are for chemical storage.

|

Name Type Model |

Specifications (MM) |

|||

|

Diameter |

Vertical Height |

Total Height |

||

|

Horizontal Water Tank |

LT-2000L |

1560*1470 |

1300 |

1390 |

LT-3000L |

2000*1520 |

1390 |

1480 |

|

|

Cone Bottom Water Tower |

CPT-30000L |

3200 |

4100 |

4500 |

|

CPT-20000L |

2700 |

3810 |

4520 |

|

|

CPT-15000L |

2700 |

2760 |

3820 |

|

|

CPT-10000L |

2300 |

2500 |

3580 |

|

|

CPT-8000L |

2300 |

2610 |

3210 |

|

|

CPT-6000L |

1900 |

2505 |

2980 |

|

|

CPT-5000L |

1900 |

1740 |

2450 |

|

|

CPT-3000L |

1580 |

2000 |

2350 |

|

|

CPT-2000L |

1320 |

1740 |

2050 |

|

|

CPT-1000L |

1070 |

1320 |

1610 |

|

|

CPT-500L |

796 |

1320 |

1500 |

|

|

CPT-400L |

770 |

1120 |

1430 |

|

|

CPT-250L |

650 |

750 |

1150 |

|

Our company provides dozens of series of rotational molding products, various specifications, suitable for various fields. Striving for professionalism is our goal; reputation plus quality is our market. Therefore, when producing storage tanks for industrial applications and water tanks for the food industry, we insist on not manufacturing inferior low-grade rotational molding storage containers. Since the establishment of the company, each storage tank's material has been calculated based on the pressure it can withstand; we have never privately reduced the materials for any tank; most of them are produced according to the specifications set by Yongcheng Company; quality guaranteed. Our water tanks are mainly used in the chemical, pharmaceutical, food, electronic aluminum foil, and environmental water treatment industries. Large specification water tanks account for a large proportion of the company's total sales, making them a competitive product in the industry. Yongcheng products will always adhere to the service tenet of "quality and customer first," sincerely providing products to a wide range of customers at favorable prices, and we warmly welcome you to provide valuable suggestions to our company. We sincerely hope to work hand in hand with you to create a grand vision together!

1、Material Selection:The material for holding water must be completely environmentally friendly and non-toxic; while the tank for storing corrosive liquids must be acid and alkali resistant and have strong corrosion resistance.

2、Color Selection::For drinking water, we generally recommend choosing the original color,but if other colors are required,the tank body needs to undergo secondary processing during production to make a double-layer,with the outer layer being colored,and the inner layer being the original color; for storing chemical liquids, especially those that react or volatilize upon light exposure, the tank body is generally made in blue or black; those with special marking functions can also be processed in red, yellow, or orange, etc.

3、Accessory Selection:Strong acids and strong bases will usePEmaterial flanges for welding; weak acids or bases can usePVCorABSmaterial accessories, which need to be configured according to actual use needs. During the product factory, we will install the accessories in the appropriate position. During transportation and unloading, the joints may loosen, so the sealing performance of the joints should be checked before use. Please note that the joints are made ofPE,PVC,ABSor nylon resin products, and if tightened too much may damage the threads.

4、Level Gauge Selection:There are three commonly used level gauges:1、TransparentPVC level tube;2、Magnetic Float Level Gauge;3、Float Level Gauge.The PVC transparent tube level gauge is inexpensive and provides an intuitive level indication; The magnetic float level gauge connects the upper and lower flanges to the container to form a communicator, allowing direct observation of the actual liquid level inside the container through the glass plate; however, the cost is relatively high; our company combines the structural characteristics of the float and magnetic float to customize a top-mounted float magnetic float level gauge based on customer needs, which is cost-effective and provides accurate positioning, gaining wide recognition from customers.

5、Reinforcement Sleeve Selection:For PE storage tanks over 15 cubic meters, Yongcheng Rotational Molding Technology recommends using metal reinforcement sleeves to avoid cracking of the hole parts of the tank body. However, for tanks containing liquids with a high specific gravity or strong acids and bases, small specification tanks may also have additional reinforcement sleeves. Please confirm with our sales representative when ordering.

1、Source Description

Yongcheng Container manufacturer direct sales

2、About Size

The specification table size, is the mold size, and the product size will shrink3%-5% and can be customized according to drawings and samples

3、About Color

Common colors are white, black, blue, and can also be customized according to your actual needs. Please confirm with our customer service.

4、About Payment

Payment can be made through third-party guarantee transactions on Alipay, or wire transfer to the company's account, with product deposits+ final payment

5、About After-Sales

Plastic water tanks come with 2 joints for free installation of joints. The product has a 7-day replacement guarantee (excluding human and irresistible factors), and free repair within one year

6、About Delivery

Due to the fact that plastic containers are throwaway, under 1m³ can be shipped by express

```

Product Consultation

Ningbo Yongcheng Rotational Molding Technology Co., Ltd.

-

Whats App

Whats App

-

Click the icon to copy service@plastmatch.com

-

Click the icon to copy +86 592 6891192 Mon - Fri, 9:00-18:00 (UTC+8)

-

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code

with your mobile

phone to download

1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app