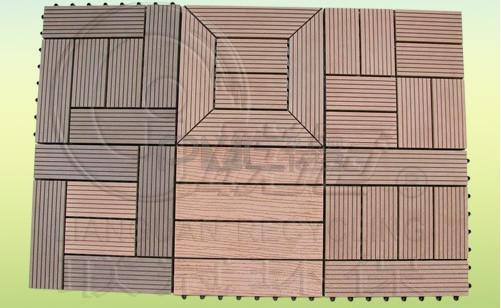

Material: WPC wood-plastic composite; Origin: Jiangsu

Function: Can replace wood and steel in many fields, reducing "white pollution" and alleviating the crisis of forest resources. Specification: 300mm × 300mm

Compressive strength is higher than that of wood and all-plastic materials; Brand: Lianguan Environmental Protection

Applicable scope: Building materials, landscaping, indoor and outdoor decoration, sports equipment, civilian facilities, municipal facilities

The main raw materials of wood-plastic composite are waste plastics and discarded agricultural straw. It is produced by adding a certain proportion of wood fiber filler (wood powder) and various processing aids to plastic granules such as PE, PP, and PVC, which are then mixed using a high mixer. Specialized processing equipment and molds are used to produce wood-plastic composite materials with the characteristics of natural wood. The raw materials and production process do not require glue for bonding, making it a new type of green and environmentally friendly composite decorative material that releases zero formaldehyde and can be recycled. It can replace wood and steel in many fields, reducing "white pollution" and alleviating the crisis of forest resources.

Wood-plastic composite materials are widely used in building materials, landscaping, indoor decoration, highways, railways, subways, ships, ports, docks, aviation, advertising, gift packaging, logistics, automotive components, industrial applications, agriculture, teaching equipment, sports equipment, civilian facilities, municipal facilities, commercial places, home appliances, and daily necessities, with broad market prospects.

Wood-plastic composite indoor decorative materials have a strength more than seven times that of wood, are rot-resistant, do not require painting, are acid and alkali resistant, can be sawed, glued, nailed, and planed, do not require fumigation or disinfection, and can be exported without inspection. They are truly environmentally friendly products.

Wood-plastic composite outdoor landscape/building materials are lightweight, cost-effective, efficient, time-saving, can achieve automatic continuous production, and can be cut to any length; products of different grades, specifications, and colors can be produced according to different raw materials and colors.

Wood-plastic composite industrial pallets/packaging materials overcome the disadvantages of wood, such as water absorption, susceptibility to insect damage, and low reuse rate, as well as the deformation issues of plastic pallets. They are more durable than wooden pallets and cheaper than plastic pallets, with good rigidity. They are an environmentally friendly new material.

Supply of PVC-PE-WPC environmentally friendly wood-plastic composite flooring - green, low-carbon, environmentally friendly and healthy - recyclable and renewable!