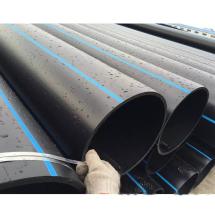

1. PE pipes for water supply are the upgraded products of traditional steel pipes and PVC drinking water pipes.

Water supply pipes must withstand certain pressure, and it is usually necessary to select high molecular weight, mechanically strong PE resins, such as HDPE resin. LDPE resin has low tensile strength, poor pressure resistance, low rigidity, poor dimensional stability during processing, and difficult connections, making it unsuitable as a material for pressure water pipes. However, due to its high sanitary indicators, LDPE, especially LLDPE resin, has become a commonly used material for producing drinking water pipes. The melt viscosity of LDPE and LLDPE resins is low, with good flowability and easy processing, allowing for a wide selection range of melt flow index, typically between 0.3-3g/10min.

Xunteng Pipes

2. Performance characteristics:

A good pipe should not only have good economic performance but also have a series of advantages such as stable and reliable connections, impact resistance, crack resistance, aging resistance, and corrosion resistance. Compared with traditional pipes, HDPE pipe systems have the following advantages:

1. Reliable connections: The polyethylene pipe systems are connected using electric heat fusion, and the strength of the joints is higher than that of the pipe body.

2. Good low-temperature impact resistance: The low-temperature brittleness temperature of polyethylene is very low, allowing safe use within the temperature range of -60 to 60°C. During winter construction, due to the good impact resistance of the material, pipes will not become brittle and crack.

3. Good resistance to stress cracking: HDPE has low notch sensitivity, high shear strength, and excellent scratch resistance, with outstanding resistance to environmental stress cracking.

4. Good chemical corrosion resistance: HDPE pipes can resist corrosion from various chemical media, and chemicals present in the soil will not degrade the pipes. Polyethylene is an electrical insulator, so it will not rot, rust, or undergo electrochemical corrosion; moreover, it will not promote the growth of algae, bacteria, or fungi.

5. Aging resistance and long service life: Polyethylene pipes containing 2-2.5% evenly distributed carbon black can be stored or used outdoors for 50 years without damage from ultraviolet radiation.

6. Good wear resistance: Tests comparing the wear resistance of HDPE pipes with steel pipes indicate that the wear resistance of HDPE pipes is four times that of steel pipes. In the field of slurry transport, HDPE pipes exhibit better wear resistance compared to steel pipes, meaning that HDPE pipes have a longer service life and better economic performance.

7. Good flexibility: The flexibility of HDPE pipes makes them easy to bend, allowing for rerouting around obstacles in engineering applications. In many cases, the flexibility of the pipes can reduce the amount of fittings used and lower installation costs.

8. Low water flow resistance: HDPE pipes have a smooth inner surface with a Manning coefficient of 0.009. The smoothness and non-adhesive properties ensure that HDPE pipes have higher transportation capacity than traditional pipes, while also reducing pressure loss and energy consumption for water transport.

9. Convenient handling: HDPE pipes are lighter than concrete pipes, galvanized pipes, and steel pipes, making them easy to handle and install, with lower manpower and equipment requirements, leading to significantly reduced installation costs.

10. Various new construction methods: HDPE pipes offer multiple construction techniques; in addition to traditional excavation methods, they can also employ various new trenchless technologies such as pipe jacking, directional drilling, lining, and bursting, making them a preferred choice for locations where excavation is not allowed, thus expanding the application range of HDPE pipes.

Shandong Xunteng Plastic Industry Co., Ltd. is one of the largest PE pipe and fitting production bases in China. It is one of the few large-scale production and processing enterprises in the country capable of producing various models of PE water supply pipes, PE gas pipes, and PE mining pipes, as well as self-matching production of PE water supply fittings, PE gas fittings, and PE mining fittings. It is also the only manufacturer in northern China capable of producing large-diameter PE fittings ranging from 800mm to 1800mm, with nationally competitive product prices! Welcome to inquire and negotiate. Contact number: 18954962733 Landline: 0539-8635528