【Antistatic Principle】

All polymer materials, if not treated for antistatic properties, conductive treatment, or other special treatments, are generally poor conductors of electric charge, with surface resistances above 1012 ohm/cm2. Adding antistatic agents to the material or its surface can effectively suppress the accumulation of static charge on the surface, reduce surface resistance, and eliminate the potential hazards caused by static electricity.

【Hazards of Static Electricity】

When two insulators come into contact and rub against each other, static electricity is generated. Static electricity can be extremely hazardous; for instance, surfaces of charged materials easily attract dust, which may damage sensitive electronic equipment, lead to difficulties, or even failures in industrial processes. Discharge of static charges accumulated on the surface of materials can also cause dust explosions or solvent fires in industrial settings.

【Function of Antistatic Liquid】

Antistatic liquid has been proven effective for the surfaces of polymers such as polyurethane, polycarbonate, PVC, and PMMA. Its main component is alky metal salts, which distinguishes it from other common antistatic agents that rely on atmospheric humidity. It remains effective even in extremely dry environments (10% relative humidity). Moreover, it remains stable at high temperatures of 300℃, making it suitable for various environmental conditions to meet the special needs of the high-tech industry.

【Key Physical Properties】

|

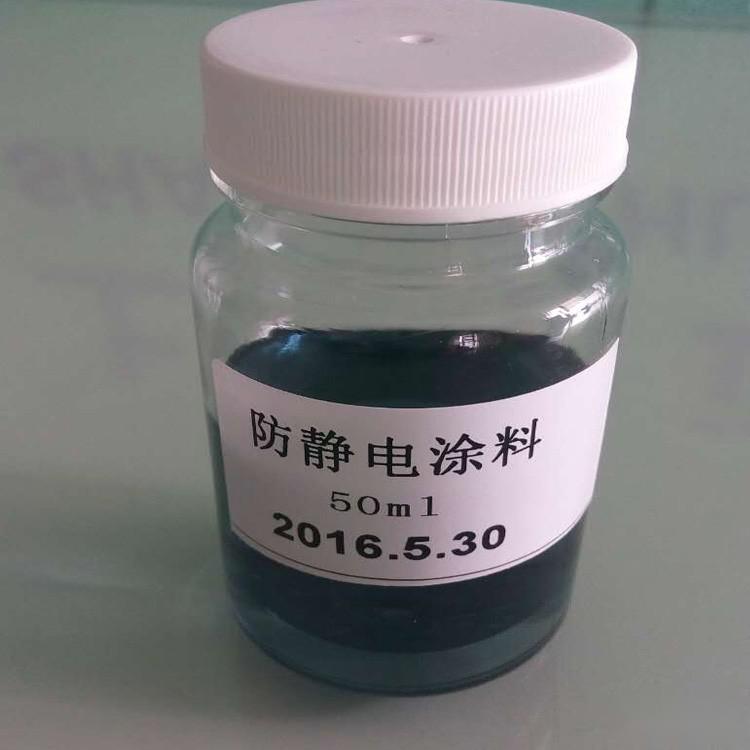

Appearance |

Light Blue Black Transparent Liquid |

|

Odor |

Slightly Irritating |

|

Water Content |

Less than 0.3% |

|

Specific Gravity (25℃) |

0.85g/ml |

|

Viscosity (20℃) |

20cps |

|

Flash Point |

99℃ |

|

pH Value |

7 ± 0.5 |

|

Solubility |

Soluble in most organic solvents and in water |

|

Thermal Stability |

Effective at 300℃ |

【Surface Treatment Characteristics】

|

Transparency |

Above 90% |

|

Surface Resistance |

106-108 Ohm/cm2 |

|

Adhesion Strength |

0 Level (Tape Test) |

|

Surface Hardness |

2H-3H |

|

Abrasion Resistance |

More than 1000 times |

|

Haze |

Less than 0.3% |

|

Glossiness |

Smooth and Flat |

|

Spot Defects |

Less than 0.01%/cm2 |

|

Applicable Temperature |

-10℃~40℃ Coating |

|

Applicable Humidity |

15%~98% Coating |

【Applicable Materials】

PC, PVC, PET, PMMA, ABS sheets, films

【Application Industries】

Semiconductor industry, LCD industry, electronic equipment and microelectronic device industry, electronics and electrical, communication manufacturing, precision instruments, optical manufacturing, pharmaceutical industry, and bioengineering, etc.

Mainly used for the construction of cleanroom facilities (semiconductors, LCD, electronics, optics, and pharmaceuticals), shielding of cleanroom equipment, partitioning of cleanroom spaces, clean equipment, observation windows, and equipment covers, and electronic testing instruments.

【Coating Methods】

Spraying, roller coating, screen printing

【Storage Conditions and Shelf Life】

Store in a dark place below 25℃, with a shelf life of more than 6 months

【Packaging Specifications】

20L/barrel