Spirax Sarco Self-Acting Temperature Control Valve KB31|KB33 Threaded Connection, Flanged Connection: Cast Iron, Bronze Balanced Bellows including: 【1】SA121【2】POCKET

The temperature changes sensed by the sensor will cause the liquid in the f} to expand or contract. When the liquid expands, it exerts pressure on the push rod, causing the valve core to act. When the liquid contracts, the force acting on the valve core decreases, and the return spring moves the valve core in the opposite direction.

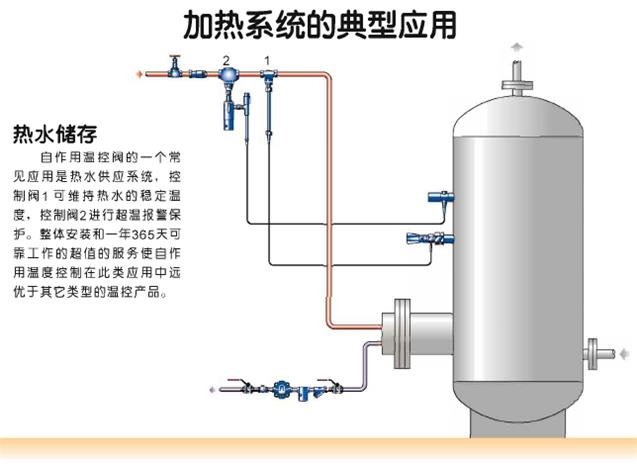

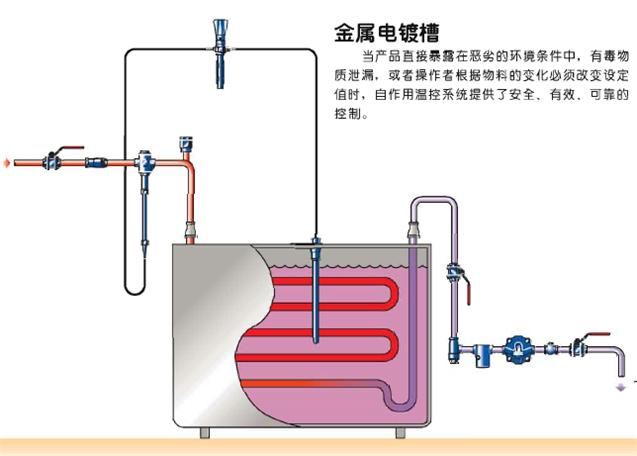

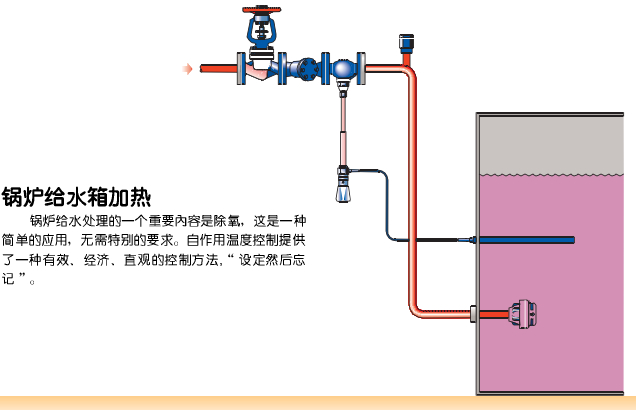

When used in heating equipment, the control valve is normally open and closes as the temperature rises.

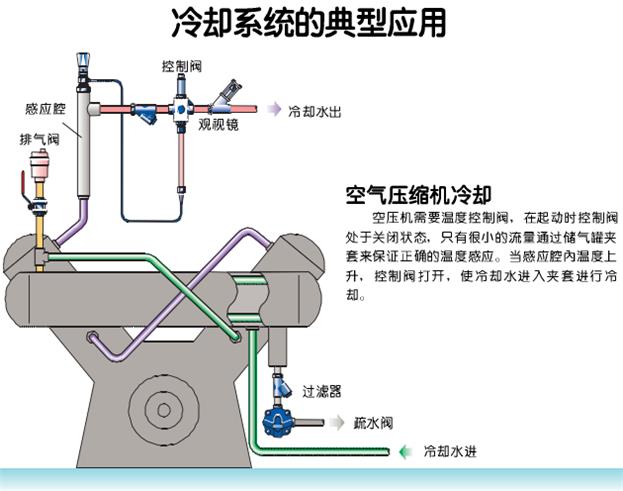

When used in melting equipment, the control valve is normally closed and opens as the temperature rises.

Spirax Sarco Self-Acting Temperature Control Valve Advantages

1. Compact size, easy installation

2. Accurate, reliable, long service life

3. Maintenance-free operation

4. Intrinsically safe working principle

5. Easy adjustment and setting

6. No worries about power or air supply interruptions

7. No need for expensive safety testing

Spirax Sarco Self-Acting Temperature Control Valve System Selection

Control Valve Selection

Is it used for heating or cooling?

For heating, the control valve should be of the normally open type, which closes as the temperature rises. For cooling, the control valve should be of the normally closed type, which opens as the temperature rises.

Control System Selection

The control system includes sensors, capillary tubes, and actuators. The matching relationship between the controller and the valve is listed on page 0' 11.

1. Is the control valve used for steam or water?

The selection table is for water.

Determine the upstream pressure P1 during normal operation.

Based on the allowable temperature range for the control point, the temperature control range can be selected from Table 5 on page 13.

Based on the application, choose the model of the control system, determine the downstream pressure P2 during normal operation, determine the flow rate of steam or water, and select the length of the capillary tube.

Body Material-

Pressure and temperature limits for brass, cast iron, and cast steel are listed in Table 3.

Connection Method-

Threaded or flanged connection. Selection methods are listed in Table 1.2.

Depending on the specific application, normally closed valves may require a small flow to achieve proper temperature control.

10. High Differential Pressure Through the Valve-

Normally open valves used in heating equipment close as the temperature rises. To ensure the valve fully closes, the sensor must overcome the high differential pressure (ΔP2) acting on the valve core. This pressure difference is generally much greater than the usual pressure drop across the valve. Similarly, the return spring of the normally closed valve must also overcome the high differential pressure to close. The maximum differential pressure for each valve is listed in Tables 1 and 2 on pages 10 and 11.