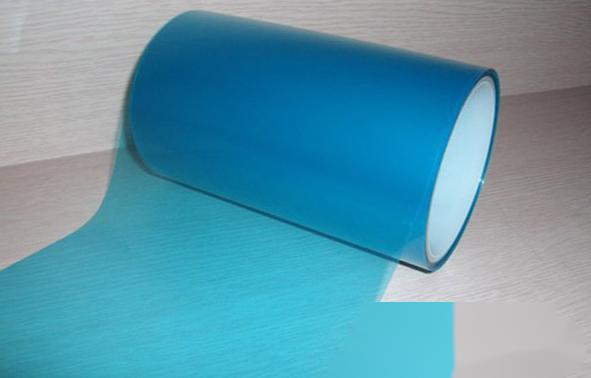

PET Release Film Product Description

PET release film, also known as PET silicone oil film, is created by applying a layer of silicone oil onto the surface of PET film to reduce its surface adhesion and achieve a release effect. It can be categorized into single-sided release film and double-sided release film. According to the release force, it can be classified into light release film, medium release film, and heavy release film. Common thicknesses include: 0.012mm, 0.019mm, 0.025mm, 0.038mm, 0.05mm, 0.075mm, 0.1mm, 0.125mm, and 0.188mm. Our factory is equipped with large slitting and cutting machines, capable of slitting and cutting according to your specifications. PET release film is now widely used in various industries such as packaging, printing, screen printing, pad printing, nameplates, membrane switches, flexible circuits, insulating products, circuit boards, laser anti-counterfeiting, laminating, electronics, sealing materials, reflective materials, waterproof materials, pharmaceuticals (for plasters), adhesive products, die cutting and stamping processing.

Release Film (High-Temperature Resistant Release Film) Performance

Xilu Optoelectronics Optical Grade PET Release Film: produced in a class 1000 cleanroom, with medium release force, clean, stable release, and good residual peel-off force.

1. No migration phenomenon, eliminating the risk of silicone resin release film transferring to the materials it adheres to.

2. The tolerance of the unit area weight of the release film's single-sided or double-sided coating is very small.

3. The base film has excellent mechanical strength and chemical properties.

4. High stability under various weather conditions, with high-temperature resistance reaching around 130°C for a prolonged period and up to 180°C for one hour.

5. Longer shelf life.

6. The release PET with adhesive is classified into light, medium, and heavy release types based on the mobility of silicone and the change in peel-off force after heating, and the release force can be controlled as required, with good heat resistance.

Release films are available in different thicknesses for customers to choose from, commonly used thicknesses are 23UM/25UM/36UM. The products are categorized into light, medium, and heavy release types, with different release forces suitable for bonding with tapes or films of varying adhesion.

Features and Applications of Release Film

Single-sided and double-sided release films, due to their superior high-temperature resistance, are primarily applied to FPC as the substrate, with a very thin layer of release agent evenly coated on one or both sides. The surface of the release film is smooth and flat, with uniform coating and no defects such as wrinkles, particles, bubbles, or pinholes. The product has excellent physical properties, small thickness tolerance, and low thermal shrinkage, making it an ideal insulating material during the processing of printed circuit boards using epoxy resin, featuring high tensile strength and tear strength.

PET release film is generally used to isolate adhesive materials and is widely utilized in industries such as electronics, mobile phones, adhesives, and printed circuit boards. The product thickness ranges from 0.025MM to 0.188MM, suitable for heat transfer printing, and particularly suitable for die-cut pads, adhesive product stamping, etc. The release force is controllable, with high gloss, cleanliness, and a residual adhesion rate of 94%, exhibiting good surface properties.

Application of Release PET Film: PET release film is used in the tape casting process of multilayer ceramic capacitors, with a commonly used thickness of 36um.