To ensure the durability of the stair treads in buildings, the stair treads are treated with edge protection usingDS cement mortar method.

Production Basis

“Quality Acceptance Norms for Building Decoration and Renovation Projects”

Construction Process

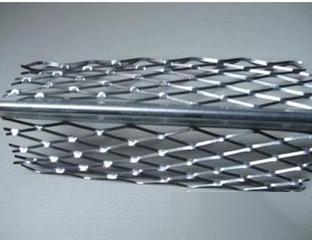

(1)Manufacturing of Stair Tread Edge Protection

(2)Installation of Stair Tread Edge Protection

The plastering method for stair treads is30mm DS cement mortar, following these procedures during construction:

Use a chalk line to snap a complete face line of the stairs on both side walls500 control line; Clean and wet the surface of the stair treads; Apply leveling mortar10 mm thick; Place the stair edge protection levelly on the surface of the leveling mortar according to the500 control line and ensure stability; Plaster the stair surface20 mm thick and finish smoothly;

Finished Product Protection

A.The plastering of the stair treads should be done from top to bottom;

B.After the installation of the stair tread edge protection, the finished surface must not be stepped on or bumped;

C.The doors to the floors where the treads are plastered must be closed on the same day to prevent unauthorized personnel from entering and damaging the completed tread surface;

D.After plastering, timely watering and curing is required, and the plastered surface should not be stepped on until7 days have passed.