Injection Stretch Blow Molding Series

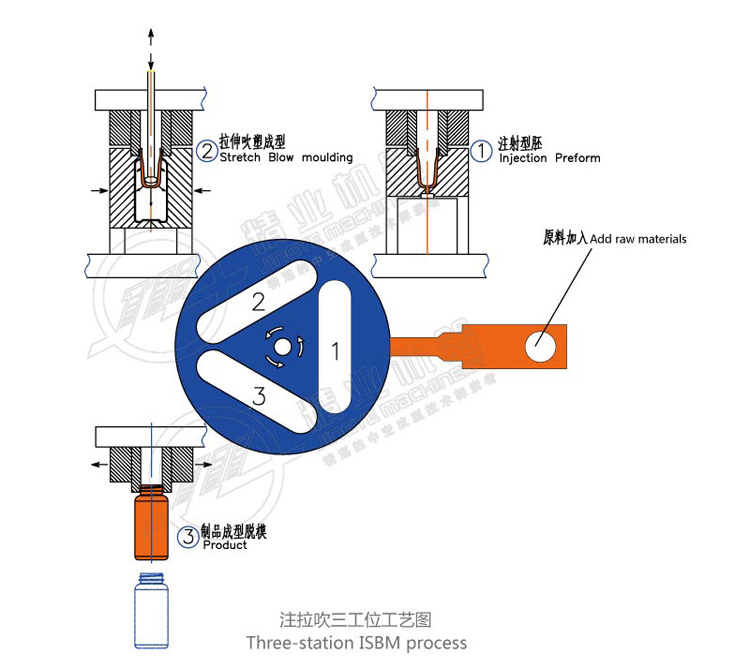

This series of machines adopts a three-station structure.

The AS model is primarily used in the packaging industry for cosmetics and pharmaceuticals, suitable for materials such as PET and PETG;

The BS model is mainly used in the packaging industry for daily items like water bottles, suitable for materials including PC, Tritan, PP, and SK resin;

The CS model is primarily used in the packaging industry for daily items like baby bottles, suitable for materials including PPSU.

The "injection-stretch-blow" production technology involves multiple stages, including the main machine, molds, and forming processes. Jingye Company has been developing this technology for over a decade.

The layout of the three-station machine is as follows: the first station injects preforms, the second station stretches and blows the bottle, and the third station removes the bottle. Its advantage lies in utilizing the residual heat from the injection-molded preform to directly perform stretch blow molding, avoiding the drawbacks of cooling and reheating the preform, which would otherwise result in repeated energy consumption. This production process reduces energy waste and ensures that products are formed in one step without intermediate transfer, completely eliminating the possibility of preform collisions and ensuring product appearance.

It can meet the market's demand for high-end product manufacturing.

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app