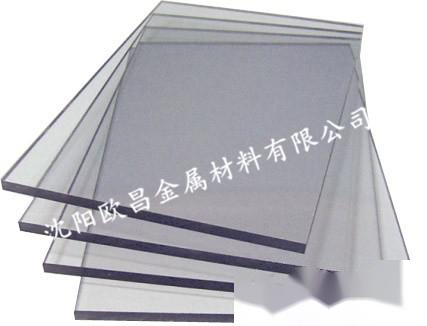

AntistaticPCSheet

Antistatic PC sheets are widely used in the construction of cleanroom facilities (semiconductors, LCDs, electronics, optics, pharmaceuticals, etc.), shielding of cleanroom equipment, partitioning of cleanroom spaces, clean equipment, observation windows, equipment covers, electronic test fixtures, and more.

The substrate is polycarbonate (PC), which is a colorless, transparent, amorphous thermoplastic material. Common antistaticPC sheets are typically treated to be antistatic by applying a coating technology that forms a hard antistatic film on the surface of standard PC sheets. This maintains the inherent physical properties of the substrate while providing excellent static elimination functionality. When the surface resistivity is between 10^6 to 10^8 ohms, it indicates the antistatic condition, effectively preventing dust accumulation and avoiding potential hazards caused by static electricity, thus meeting the special needs of various industries in the high-tech era.

Features:

The features of antistatic PC sheets include strong impact resistance (PC is also known as bulletproof plastic), the ability to withstand temperatures up to 120℃ (for example, PC material used for baby bottles can be sterilized in boiling water at 100℃), excellent flame retardancy (flame retardant rating is UL-94 V-0~V-2, and sheets with a thickness of 6mm or more can achieve a V-0 rating, which is higher than V-2); light transmittance is 83%. The manufacturing process for antistatic PC sheets is extrusion, with a thickness tolerance typically ranging from 3-5 mils. They exhibit high mechanical strength and excellent processing performance.

Applications:

Suitable for semiconductor industry, LCD industry, electronic equipment and microelectronics industry, electronics and electrical, communications manufacturing, precision instruments, optical manufacturing, pharmaceutical industry, and bioengineering, among others.