Liquid Rubber (LNBR)

Liquid Rubber (LNBR)

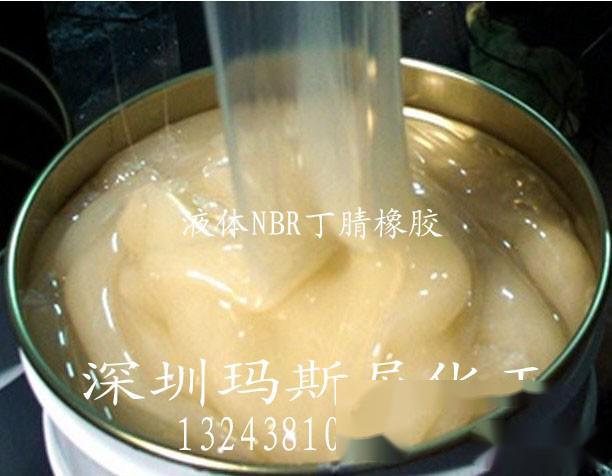

The liquid series (LNBR) is a rubber that has a main chain structure of butadiene and acrylonitrile, which may or may not contain other functional groups, and is in a viscous liquid state at room temperature. Its number average molecular weight is usually below 10,000. LNBR is a new type of low molecular weight liquid toughening agent, plasticizer, and rubber softening agent. The liquid is a viscous liquid rubber developed based on rubber. It is pale yellow, transparent, and odorless. Liquid functions: reactive plasticizer & softener.

As a special variety of rubber, the production scale and output of liquid rubber are very small, with manufacturers such as China National Petroleum Corporation Lanzhou Petrochemical Company producing less than 100 tons annually.

2. Product Performance Introduction:

From the perspective of "plasticizers", the liquid is a high molecular weight rubber with plasticizer functions.

In the rubber vulcanization process, the liquid is "vulcanizable" (can co-vulcanize with sulfur or peroxides).

From the perspective of "processing aids", the liquid is a physical and chemical modifier with softening agent functions.

It can improve the following properties of rubber:

1) Improve processing operability (flowability of the rubber compound; stiffness of low hardness rubber; flexibility of high hardness rubber; self-adhesiveness during rubber processing, etc.);

2) Enhance the physical and processing properties of low hardness rubber products;

3) Improve mechanical properties when used with white carbon black or clay;

4) Improve adhesion to metal materials and glass materials when using LXNBR;

5) Co-vulcanization can be achieved when used with NBR, CR, ACM, FKM, CSM, ECO, SBR, etc.

6) No migration in the products and no extraction in solvents, improving the aging resistance and chemical resistance of the products.

From the perspective of production scale and application range, liquid rubber occupies an important position among all liquid rubbers, with a relatively large variety and grade. Liquid rubber typically contains functional groups. From the perspective of molecular chain structure, liquid rubber is divided into three categories: the first category does not contain functional groups; the second category has functional groups distributed randomly in the molecular chain; the third category has functional groups only at the ends of the molecular chain. Specific grades are further divided according to the content of acrylonitrile and the size of molecular weight.

The synthesis of liquid rubber (LNBR) mainly adopts a free radical polymerization process, specifically emulsion polymerization and solution polymerization based on the free radical mechanism.

The emulsion polymerization process is shown in the diagram:

When preparing liquids through solution polymerization, the amount of solvent used is very small, approximating bulk polymerization. The process flow is shown in the diagram:

Liquid can be widely used in PVC resin, SBS/ABS and other thermoplastic elastomers and rubbers, acrylic rubber, fluorine rubber, hydrogenated rubber, chloroprene rubber, and other specialty rubbers.

(1) Plasticizer modifier for polyvinyl chloride resin (PVC)

Using liquid (LNBR) can replace DOP, DBP, DOA, DOS, and solid plasticizer powder, while improving the cold resistance, heat/light/aging resistance, oil resistance of PVC, enhancing the rebound, impact resistance, and surface molding effect of products, and improving the migration of plasticizers in products. It can be used to produce: wire and cable materials, automotive dashboards, automotive bumpers, plastic films, irrigation water pipes, mining conveyor belts, shoe industry, brake pad industry, etc.

(2)Plasticizers

Due to the good compatibility of liquid (LNBR) with other rubbers, it is not easily extracted by solvents, making it suitable as a non-extractable specialty plasticizer. When making printing rollers, using liquid rubber to replace black and white paste or dioctyl phthalate as a softening agent can enhance the processing performance of the rubber rollers and improve the strength, elongation, and rebound of the products, as well as enhance the performance and printing quality of the rubber rollers.

(3)Adhesives

Liquid (LNBR) has excellent oil resistance and adhesion, and good fluidity, and can be combined with phenolic resins, epoxy resins, etc., to produce adhesives with strong bonding strength, good rebound, and oil resistance.

(4)Coatings

Liquid (LNBR) can be used to manufacture low-temperature coatings, anti-corrosion coatings, electrical insulation coatings, water-soluble and electrophoretic coatings, and has advantages such as toughness and impact resistance.

(5)Application in solid rocket propellants

In solid rocket propellants, liquid (LNBR) is used as an adhesive.