Main products

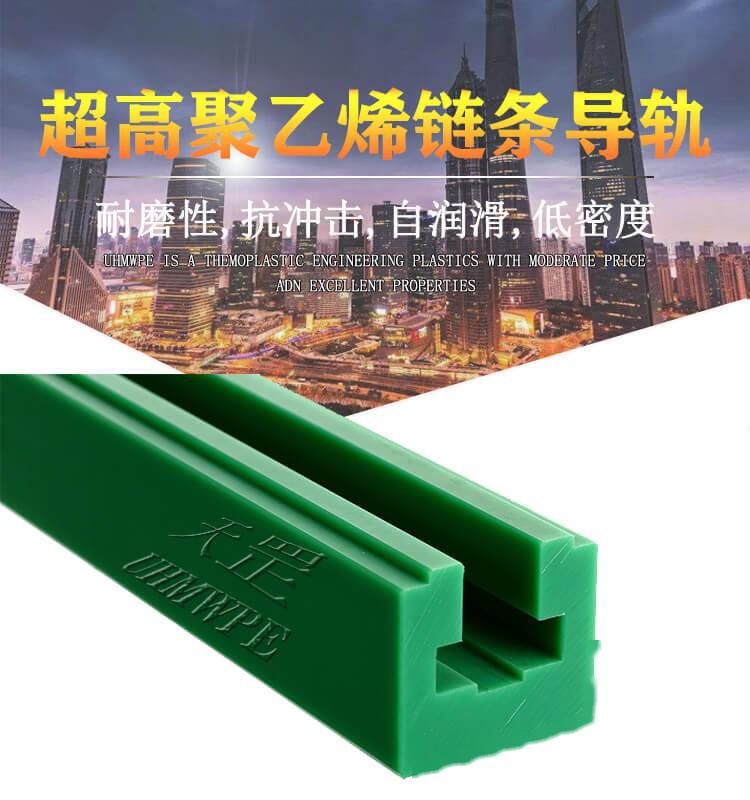

Ultra-high molecular weight polyethylene pipes, conductive type, weather-resistant type, synthetic ice panels, wheels, textile machinery parts, anti-static type, ski board sidewalls, UPE guardrails, plate-type guardrails, escalators, high molecular weight sliders, ultra-high molecular weight polyethylene rollers, flame-retardant buffer blocks, high-temperature resistant type, high-hardness type, logistics and warehousing, food and beverage packaging, chain guides, industrial automation, ultra-high molecular weight polyethylene films, high-strength type, conveyor guardrails, UPE films, strips, UPE sliders, friction strips, UPE rollers, photovoltaic accessories, wear-resistant sliders, chain tension blocks, buffer strips, high molecular weight strips, support strips, high-lubricity type, seals, ultra-high molecular weight polyethylene sheets, food and beverage machinery parts, ultra-high molecular weight polyethylene rods, wear-resistant strip pads, parallel guide rails, port machinery parts, two-color type, guide strips, wear-resistant strips, flame-retardant and anti-static type, UPE one-piece molded parts, wear-resistant edge strips, high molecular weight buffer strips

About Us

Shanxi Tian Gang New Material Technology Co., Ltd. is a high-tech specialized company that continuously strives to excel in the research, development, production, processing, and sales of ultra-high molecular weight polyethylene (UHMW-PE) series products. The company is located in Xiaoyi City, Shanxi Province, within the High-Tech Industrial Park, enjoying convenient transportation and a beautiful environment. Founded in 2004, the company covers an area of 46,000 square meters, with a factory space of 20,000 square meters and office space of 2,000 square meters, and has a registered capital of 10 million yuan. The company primarily focuses on the R&D and production of UHMW-PE sheets, rods, films, idlers, chain guides, wear strips, and various custom-shaped parts. It boasts domestic leading, world-class sheet production lines, including 6 three-station four-layer production lines, 100 patented extrusion lines, 6 special extrusion lines, 6 custom pressing machines, CNC machining centers, and a variety of machining equipment. The pressure of the sheet production line can reach up to 1,200 tons per square meter, the highest in China. Our products are made from the best raw material supplier, TICONA GUR, ensuring our product quality leads the industry. Our sheet specifications include 1240*3075*(12~120mm), 1000*2000*(5-150mm), 1415*2020*(4~30mm), and 2000*4000*(5-150mm). We are the only company in China capable of producing mirror-finished surfaces, with minimal thickness tolerance. After being processed by specialized equipment, the one-time molding extrusion technology allows us to customize various high-quality rods (Φ15―Φ300mm) and other components used in packaging equipment, such as wear strips, guardrails, and chain guides, according to customer requirements. We can also adjust colors based on customer needs. Currently, we produce over 2,500 tons of UHMW-PE sheets, 500 tons of rods, and 250 tons of various custom-shaped parts annually.