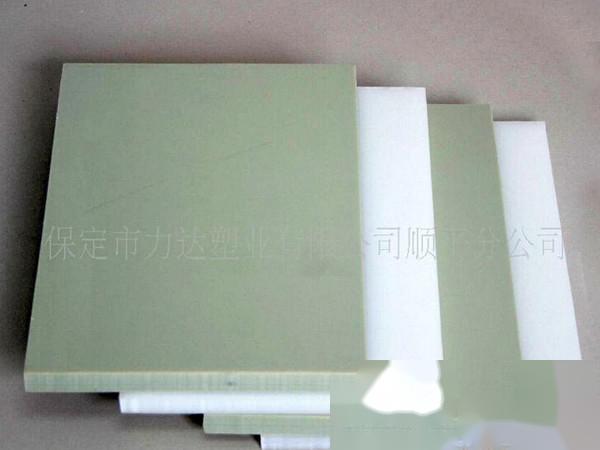

Length: Above 1.5 Manufacturer: Baoding Lidar Plastic Industry Co., Ltd. Thickness: 2mm~50mm

Weight per piece: 0.915~0.93 Use: Electroplating equipment, anticorrosion equipment, mechanical equipment, electronic equipment Large width: 1.5

Pure PP board: Small density, easy to weld and process, with excellent resistance to chemicals, heat, and impact, non-toxic, odorless, is one of the engineering plastics that currently meets environmental requirements. The main colors are white, beige, and other colors can also be customized according to customer requirements.

Modified PP board (calcium plastic board): Good dimensional stability, low price, rigidity, heat resistance, etc. are all improved compared to pure PP. The colors are generally green, white, and beige. Mainly used for making water tanks and three-phase separators.

Fiber reinforced PP board (FRPP board): After being reinforced by 20% glass fiber, it not only maintains its original excellent performance, but also doubles the strength, rigidity, etc. compared to PP, and has good heat resistance, low temperature impact resistance, corrosion resistance, arc resistance, and low shrinkage rate. It is especially suitable for fields such as chemical fiber, chlor-alkali, petroleum, dyes, food, medicine, light industry, metallurgy, sewage treatment, etc.

PP board is a semi-crystalline material. It is harder and has a higher melting point than PE. Because the homopolymer type of PP is very brittle above 0°C, many commercial PP materials are random copolymers with 1-4% ethylene or block copolymers with higher ethylene content. Copolymer type PP materials have lower heat distortion temperature (100°C), low transparency, low gloss, low rigidity, but stronger impact resistance. The strength of PP increases with the increase of ethylene content. The Vicat softening temperature of PP is 150°C. Due to the high crystallinity, this material has good surface rigidity and scratch resistance. PP does not have environmental stress cracking problems. Usually, PP is modified by adding glass fiber, metal additives, or thermoplastic rubber. The melt flow rate (MFR) of PP ranges from 1 to 40. PP materials with low MFR have good impact resistance but low elongation strength. For materials with the same MFR, copolymer type PP has higher strength than homopolymer type. Due to crystallization, PP has a relatively high shrinkage rate, generally 1.8-2.5%. And the directional uniformity of shrinkage is much better than PE-HD and other materials. Adding 30% glass additive can reduce the shrinkage rate to 0.7%. Both homopolymer type and copolymer type PP materials have excellent moisture resistance, acid and alkali corrosion resistance, and solvent resistance. However, it has no resistance to aromatic hydrocarbons (such as ) solvents, chlorinated hydrocarbons () solvents, etc. PP also does not have the oxidative resistance at high temperatures like PE.

Application range: Acid and alkali resistant equipment, environmental protection equipment, waste water and waste gas emission equipment, scrubbing tower, clean room, equipment for semiconductor factories and related industries, also the material for making plastic water tanks, where PP thick boards are widely used for stamping plates, punch cushion plates, etc.