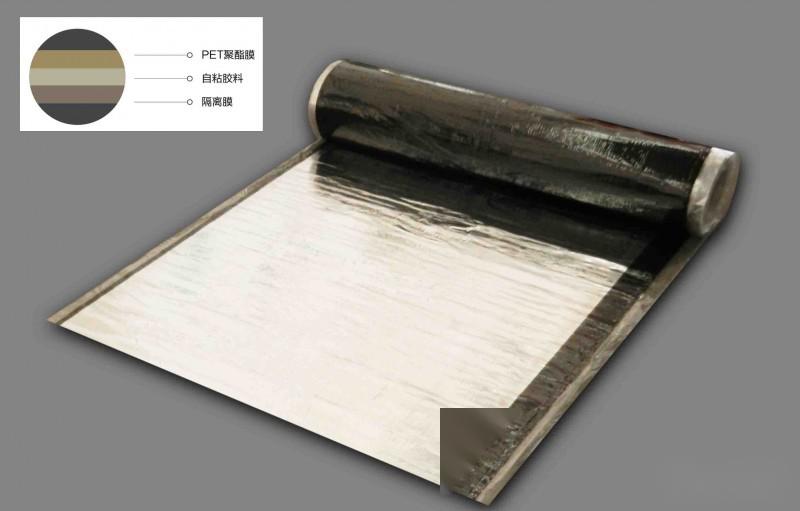

HNP composite self-adhesive rubber asphalt waterproofing membrane is made of polyester composite film (aluminum-plated, aluminum-plastic composite) as the surface material, coated with rubber asphalt adhesive material, and then a layer of self-adhesive rubber asphalt material with creep function is applied on its upper or lower surface, followed by a silicone foil anti-adhesion isolation membrane. This high polymer self-adhesive waterproofing membrane combines the unique properties of polymer materials, such as high strength, high elongation, and aging resistance, with self-adhesive bonding, self-healing, and enhanced load protection functions, making it an ideal waterproofing material for subways, tunnels, caverns, and basements. Contact: Manager Yang, Order Phone: 18664834088, Corporate QQ: 523776826

2. Product Features

Excellent physical properties: The composite self-adhesive rubber asphalt waterproofing membrane has aging resistance, high elongation, stable dimensions, and excellent weather resistance and corrosion resistance!

Bonding performance: The composite self-adhesive rubber asphalt waterproofing membrane forms a physical-chemical bonding layer with the structural layer through chemical reactions and physical adsorption with polymer cement, resulting in a bonding strength far greater than that of physical adsorption.

Excellent waterproofing effect: It has a "water-locking" function, does not diffuse, is easy to maintain, and has strong self-healing capability;

Simple construction process: Reliable overlaps solve problems in tunnels and winter construction, have low requirements for the substrate, shorten construction periods, save costs, and form a tight bonding layer through interaction with polymer cement slurry.

3. Scope of Application

(1) Waterproofing and anti-seepage for various underground projects, such as basements, civil air defense projects, subways, etc.

(2) Waterproofing for roofs and exterior walls of industrial and civil buildings.

(3) Moisture-proof and waterproof projects for grain warehouses and electronic workshops that are sensitive to moisture.

(4) Waterproof and anti-corrosion projects in coastal areas subject to seawater corrosion and significant structural deformation.

4. Packaging, Storage, and Transportation

1. During transportation and storage, products of different types and specifications should be stacked separately and not mixed.

2. Avoid exposure to sunlight and rain, and ensure ventilation.

3. The storage temperature should not exceed 45°C.

4. When stored flat, the stacking height should not exceed five layers; when stored upright, it should be single-layer stacked.

5. During transportation, prevent tilting or lateral pressure; use tarpaulin when necessary.

6. Under normal transportation and storage conditions, the product's storage period is at least one year from the date of production.

5. Precautions

1. The membrane should be protected from direct sunlight to avoid high temperatures that make the isolation membrane difficult to peel off.

2. If the temperature is too high, a suitable amount of water-retaining agent can be added to the cement adhesive to ensure effective curing.

3. If the isolation membrane is difficult to remove due to high temperatures, it can be cooled by spraying cold water on the isolation membrane surface before removal.

4. After laying the membrane, avoid stepping on it; subsequent construction can only proceed after the cement adhesive has cured.

5. Before construction, consult Hongniu Company for information such as manuals or construction plans.

6. Specifications and Models

Width: 1.0m

Thickness: 1.2mm, 1.5mm, 2.0mm

Length: 20m

Note: Other specifications and dimensions can be determined through negotiation between the supplier and the buyer.