In the field of plastic recycling, pyrolysis technology has attracted much attention for its ability to decompose waste plastics. However, existing pyrolysis methods have significant drawbacks, including a wide range of molar mass distribution in the products and low yield. Although catalysts can improve yield and selectivity, they are costly and have limited lifespan. Recently, researchers at Yale University have made a breakthrough by developing a method that is expected to improve both indicators simultaneously. Led by Professors Wenbin Liang and Shu Hu from the School of Engineering at Yale, the team has developed a highly selective, energy-saving, and catalyst-free pyrolysis method that can convert plastics into valuable chemicals, bringing new hope for the recycling and reuse of plastics.

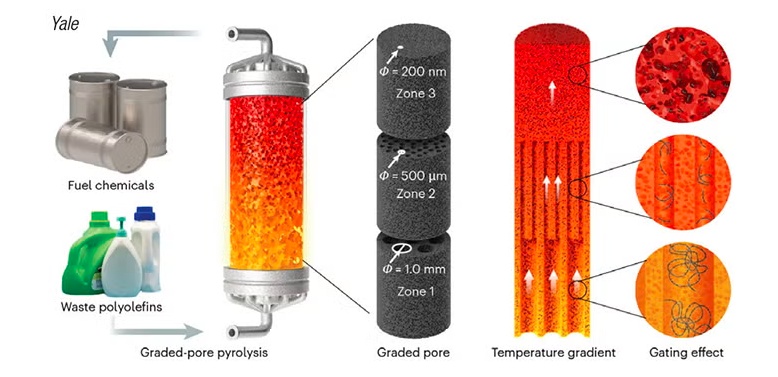

The key to this study lies in a 3D-printed electrically heated carbon column reactor, which consists of three sections with decreasing pore sizes (as shown in the schematic). The researchers used 3D printing technology to construct the reactor structure, enabling precise control of the pore sizes within the reactor, thereby facilitating an in-depth investigation of the pyrolysis effects. The first section of the reactor has pores of 1 millimeter, the second section has pores of 500 micrometers, and the third section is composed of pores measuring 200 nanometers.

Researchers introduced that when chemicals flow through the reactor, this layered porous structure plays a key role in controlling the chemical reaction process. The reactor's design is ingenious, preventing large molecules from passing through before fully decomposing, while effectively controlling the temperature inside the reactor to avoid phenomena such as coking that would affect the reaction progress. Researchers tested the reactor using polyethylene as the raw material, and the results showed that nearly 66% of the plastic waste was converted into hydrocarbons sized similarly to automotive fuels (C8 - C18), setting a new record for yield.

To demonstrate a more scalable design, researchers also conducted experiments using devices made from commercially available carbon felt. They found that even without the optimization offered by the 3D-printed structure, this design still improved the selectivity of pyrolysis products and achieved satisfactory yields, converting more than 56% of the plastic into useful chemicals.

Assistant Professor of Chemical and Environmental Engineering at Yale University, Hu Shu, stated: "These results are very promising, showing the great potential of this system in practical applications and providing a feasible strategy for converting plastic waste into valuable materials." The research findings have been published in the journal Nature Chemical Engineering.