Why Single-Screw Extruders Cannot Replicate the Mixing Performance of Twin-Screw Extruders

People often ask:Why can't the mixing or compounding performance of corotating parallel twin-screw extruders be replicated on single-screw extruders?

Core advantages of twin screws:

Full-thread mixing and precise shear control

First, the twin screws can transfer the entire channel filled with polymer from one screw to the other multiple times, thereby achieving...Full-thread mixing.

In implementing such full helical groove mixing transfer, most of the polymer can be subjected to very low shear by simply changing the depth of the opposing helical groove or using mixing ribs, while only a small portion of the polymer is subjected to extremely high shear.

Additionally, the screw operates in an idling state, providing sufficient space for such transmission. Due to the meshing of the screw elements, the pressure drop of this transmission is very small, resulting in minimal yield loss.

Limitations of single screw:

The contradiction between pressure drop and shear distribution

In a single screw, the pressure drop through the high shear zone (which is necessary for intensive mixing) is a limiting factor because it leads to reduced throughput and increased melt temperature. A twin screw can achieve equally intensive and thorough mixing without overheating by repeating this process multiple times.

To fully disperse additives or even other polymers, regardless of the type of extruder, high-shear intensive mixing is required because many materials are only partially compatible with each other or form agglomerates that require high shear to break.

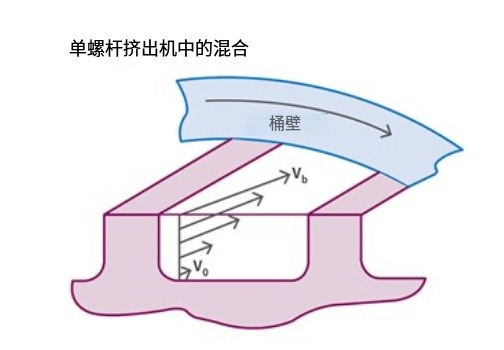

Mixing in a single screw is primarily limited by the passage of the polymer along the channel of the screw. The shear rate and the resulting downstream velocity are highest at the barrel or channel top, and lowest or possibly zero at the screw root.

Mixing in a single screw is primarily constrained by the screw channel as the polymer flows along the screw. The shear rate and the resulting downstream velocity are highest at the barrel wall or the top of the screw channel, and lowest or possibly zero at the screw root. Because the polymer, once melted, adheres firmly to the surfaces of both the barrel and the screw, the shear force generated as the polymer rotates with the screw inside the barrel becomes the main driving force. Essentially, in the force balance acting on the polymer, the barrel rotates around the screw, and the moving surface where the barrel contacts the polymer provides the conveying action. In the accompanying figure, these velocities are represented as V.bAnd V0。

The stratification of velocity also results in only partial "turnover" of the polymer within the screw channel. This alone makes it difficult for the material in the screw channel to be completely mixed. In addition, due to the continuous shear thinning of viscosity from the barrel wall to the root of the screw, the material in the single-screw channel tends to remain at relatively the same radial position.

Flexible design of twin screws:

The balance between multiple high shear and overall shear

To overcome this limitation, various types of mixers and additional threads are used to break and redirect the polymer melt flow. However, these devices generate flow resistance, reducing output and increasing melt temperature. All polymers must repeatedly flow through such devices to achieve uniform mixing.

Twin screws can apply high shear in small increments by repeatedly changing the screw groove depth and/or using mixing protrusions, while keeping the overall shear on the entire melt limited. This is difficult, if not impossible, to achieve with a single screw, as it requires tight clearances or flow path restrictions to generate high shear rates.

A single screw must have a specific screw channel depth to achieve the desired output and melt temperature. This limits the use of multiple high shear zones, which is very useful for twin screws because the material exchange between the screws allows for the transfer of the polymer to another screw channel, applying strong shear to only a small portion of the polymer.

The function of the Maddock mixer

There are many single-screw mixing and barrier flight designs that can increase some mixing within a single screw, although most primarily help the melt by preventing the passage of unmelted material. Interestingly, one of the earliest and most popular single-screw mixers is the Maddock-type mixer, which combines two principles of twin-screw mixers. One is the complete "turnover" of the entire melt, and the other is the application of short-term high shear as the polymer passes through the barrier from the inlet to the outlet flight.

The Maddock mixer is designed with the characteristics of twin-screw mixing in mind: complete turnover of the polymer and limited high shear.

Although fundamentally quite effective, it is mainly limited to "single-use" applications because its inherent pressure drop reduces throughput and significantly raises melt temperature, making it difficult to use multiple mixing sections. There are also spiral Maddock designs, but their improvement in pressure drop is minimal. Many other single-screw mixers merely divide the melt under low shear, primarily to homogenize temperature, lacking the high shear necessary for strong mixing.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track