Twin screw extruder selection guide: How to Choose Between Co-rotating, Counter-rotating, and Conical Types?

In modification production, Embrittlement, cracking, or insufficient ductility. These problems are often not due to the formulation itself, but rather to a misunderstanding of the extruder's conveying characteristics, mixing capability, and shear distribution.

In-depth deconstruction of the above text. Twin-screw extruder geometric classifications and performance differences. , helping you precisely control "calendering effect" and "positive displacement conveying." Addressing the Production Pain Points of Thermal-Sensitive Material Decomposition and Uneven Mixing in High Filling Applications from the Source. 。

1.Classification of Twin-Screw Extruders

Twin-screw extruders can be classified in many ways, and various classification methods have been proposed by individuals such as Erdmenger, Farrizo Martelli, and Chris Rauwendaal. While these methods have their similarities and differences, they can generally be categorized as follows:

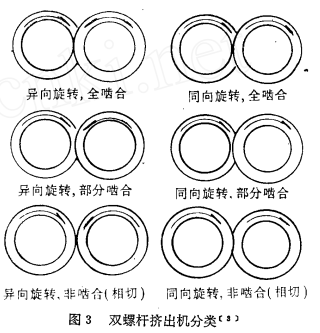

Intermeshing and Non-intermeshing Twin-screw Extruders

Non-intermeshing twin-screw extruder Its geometric characteristic is that the distance between the axes of the two screws is at least equal to the sum of the outer radii of the two screws, i.e., I < R1 + R2. If I = R1 + R2, it is also called an externally tangential or tangential twin-screw extruder.

Intermeshing twin-screw extruder The distance between the screw axes of the two screws is less than the sum of their outer radii, i.e., I < R1 + R2. Because the flight of one screw inserts into the screw channel of the other, it is called an intermeshing type. Based on the degree of intermeshing, it is further divided into fully intermeshing and partially intermeshing (or non-fully intermeshing) types. Fully intermeshing means that there is no gap between the flight tip of one screw and the root of the screw channel of the other screw (in terms of geometric design, not manufacturing and assembly). Partially intermeshing means that there is a geometric gap between the flight tip of one screw and the root of the screw channel of the other screw.

In describing intermeshing twin-screw extruders, the concepts of conjugate and non-conjugate are sometimes used. Conjugate refers to the situation where the flight of one screw and the channel of the other screw have similar geometric shapes, fitting closely together with only a small (manufacturing and assembly) gap. Non-conjugate, on the other hand, means that the flight of one screw can fit loosely into the channel of the other screw, with a large gap left around the perimeter (intentionally left geometrically). It is evident that conjugate and intermeshing are different. Partial intermeshing can be regarded as non-conjugate, but full intermeshing is not equivalent to conjugate.

Based on whether the meshing area is open or closed.

Open and closed refer to whether there are possible channels for material flow along or across the thread grooves in the meshing area (excluding clearances for manufacturing assembly). Based on this, they can be categorized as longitudinally open or closed, and transversely open or closed, among others.

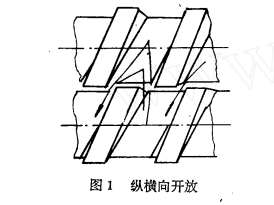

If a conveying channel exists for material from the feeding zone to the screw end, allowing material to flow from one screw to another (i.e., flow along the screw channel), it is called longitudinally open (Figure 1). Conversely, it is called longitudinally closed.

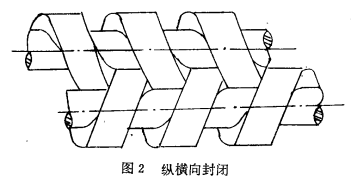

Longitudinal sealing means that several mutually isolated chambers are formed on each of the two screws, and the screw flight of one screw is completely blocked by the screw land of the other screw. There is no material exchange between the two screws (Figure 2).

In the engagement zone of twin screws, if there is a channel for material to pass across the screw flights, meaning that material can flow from one screw channel of one screw to the adjacent screw channel of the other screw, or material from one screw channel of one screw can flow to two adjacent screw channels of the other screw, it is called transversely open (Figure 1); otherwise, it is called transversely closed (Figure 2).

According to the rotation direction of the twin screws

Accordingly, twin-screw extruders can be classified into co-rotating and counter-rotating types. The former rotates in the same direction, while the latter rotates in opposite directions.

According to whether the two screw axes intersect or are parallel.

If the axes of the two screws are parallel, it is called a parallel twin screw, also known as a cylindrical twin screw; if the axes of the two screws intersect, it is called a conical twin screw.

2.Performance and Applications of Twin Screw Extruders

Co-rotating twin-screw extruder

Intermeshing co-rotating twin-screw extruders are a major category of twin-screw extruders. Geometrically, in the intermeshing zone, the screw channels are closed laterally, or they can be open. However, they cannot be closed longitudinally, otherwise interference will occur. That is, the screw channel width must be designed to be greater than the screw flight width to ensure longitudinal openness.

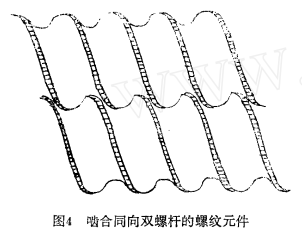

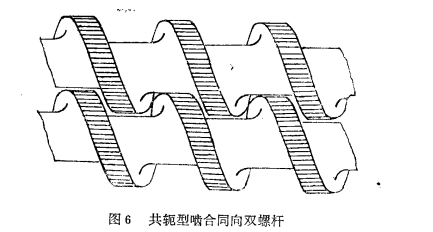

The screw thread shape of co-rotating twin-screw extruders widely used both domestically and internationally (especially in China) is often designed based on the principle of relative motion. These screws feature screw flights that are significantly narrower than the screw channels, transverse closure, longitudinal openness, and large channels (Figure 4).

The material in one screw can flow smoothly into another screw, and is conveyed forward along a helical channel. It is fully intermeshing but non-conjugate, with poor sealing between the screw flight and the screw channel, and material backflow easily occurs. From the perspective of conveying mechanism, it combines frictional drag conveying and positive displacement conveying. The larger the longitudinal opening, the greater the loss of positive displacement conveying capacity, and the greater the effects of friction drag and viscous drag. 。

This co-rotating twin-screw extruder has the following features: :

(1) In threaded elements (including thread groove and meshing zones), the shear rate distribution is relatively uniform, which is beneficial for distributive mixing; in kneading disc elements, High shear rate, intense mixing, conducive to dispersive mixing. ;

(2)Possesses good self-cleaning properties. ;

(3) Can operate at high speed (up to 300-600 r/min), resulting in relatively high production.

(4) Possessing lower conveying characteristics and general conveying efficiency, its pressure build-up capability is relatively low. This is because it cannot be used to directly extrude products (except for granulation). To obtain high extrusion pressure, a gear pump or a second-stage single-screw extruder needs to be connected downstream.

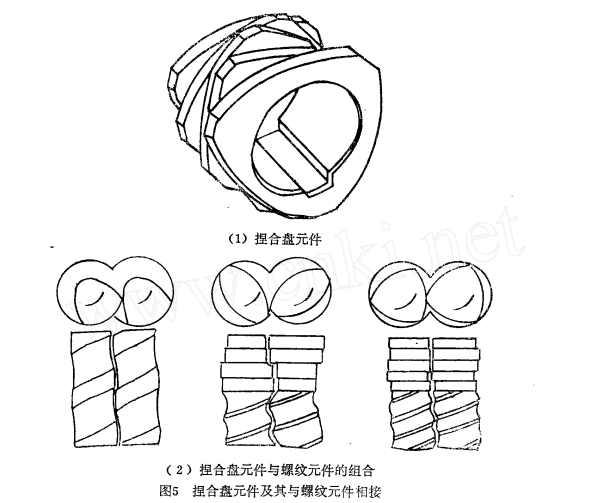

The screws and barrel of a co-rotating twin-screw extruder are made in modular segments. Screw elements include threaded elements, kneading disc elements, and toothed elements. 。

Positive thread insert Delivery element. Single-head design for high delivery volume.

Twin-head shearing is gentle, mixing is balanced, and conveying is the most common; triple-head shearing is strong but has low conveying capacity.

Reverse threaded component Resistance element for forming a seal and establishing high pressure.

Kneader disc element : Possesses excellent mixing and melting capabilities. Adjacent kneading discs are installed with a certain stagger angle (Figure 5). A string of kneading discs can form neutral, forward, or reverse axial conveying.

If the thread profile of twin screws is designed to be conjugate (but with narrower screw ridges than screw channels), as shown in Figure 6, the conveying capacity is better, but it can only operate at low speeds (10~20 r/min). Otherwise, high pressure will be generated in the meshing area, leading to wear. This is called ______. Low-speed twin-screw extruder 。

2. Counter-rotating twin-screw extruder

Intermeshing counter-rotating twin-screw extruder

Low-speed type (conjugate) ): The meshing area is sealed both longitudinally and laterally, and the conveying mechanism is positive displacement. It is characterized by extremely strong positive displacement conveying capacity and high pressure build-up capability, and is mainly used for processing RPVC granulation or extruded profiles. Limited by the calendering effect, it can only operate at low speeds (10~50 r/min).

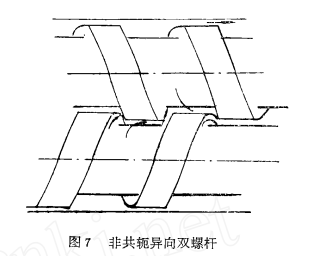

High-speed (non-conjugated) As shown in Figure 7, the gap is relatively large. During high-speed operation (200~300 r/min), the material is subjected to high shear and tension in the gap, resulting in rapid surface renewal and high mixing and melting efficiency. It is mainly used for the preparation of highly filled materials, alloys, and reactive extrusion.

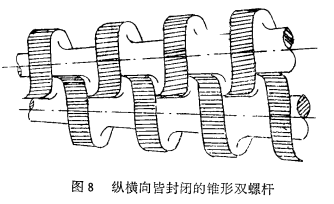

(2) Conical twin-screw extruder

The working mechanism is basically the same as that of parallel counter-rotating type. If designed to be closed in both longitudinal and transverse directions (Figure 8), it is mainly used for RPVC product processing.

Compared with parallel twin-screw extruders, conical twin-screw extruders have the following advantages: ① Deeper screw channels and larger diameter in the feeding section, resulting in better feeding characteristics; ② Lower circumferential speed at the discharge end, preventing melt over-shear decomposition, suitable for RPVC processing; ③ Easier thrust bearing design; ④ Smaller back pressure and rotational resistance at the discharge end.

3. Non-intermeshing twin-screw extruder

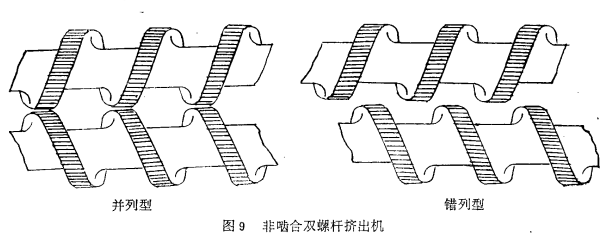

Generally, inward heterorotation is classified into parallel and staggered types (Figure 9).

Its conveying mechanism is similar to that of a single screw extruder (friction drag). The mixing rate is exponential, with excellent distributive mixing capability but limited dispersive mixing capability. It possesses superior devolatilization capability. It is primarily used for compounding, filling, glass fiber reinforcement (low fiber breakage), and reactive extrusion (L/D ratio can reach 120). Due to its low pressure build-up capability, it cannot directly extrude products.

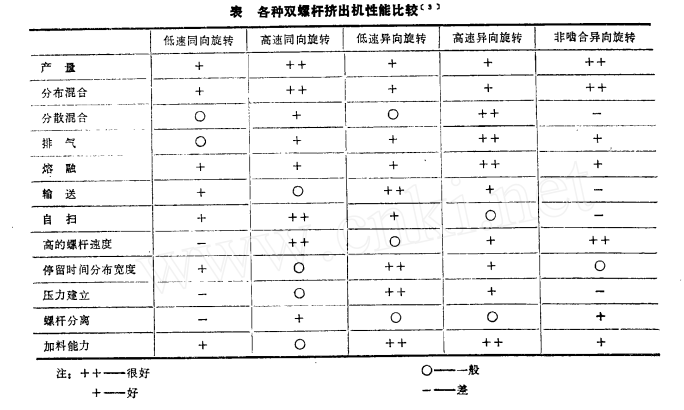

The above is a simple overview of... Performance of various twin-screw extruders The above has been introduced. To comparatively deepen the understanding of them, the following table lists the comparison of their performance in several aspects, as the conclusion of this article.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories