The "Superpower" of Filler Modification: How to Reshape 6 Core Physical Properties of Plastics

In the field of new material modification, filler modification is a highly cost-effective technological approach. By adding specific fillers to the plastic matrix, it can not only reduce production costs and adjust processing performance but also precisely improve several key physical properties such as hardness, friction, and thermal performance. Furthermore, it can even endow materials with new functionalities like conductivity and magnetism.

I. Hardness

The hardness of plastic is essentially a measure of its elastic modulus. The addition of fillers can significantly increase the modulus of filled plastics, thereby enhancing hardness.

In hardness measurement, two commonly used methods have their respective applicable scenarios.

Ball indentation hardness: Under a specified load, a steel ball is pressed into a plastic specimen, and the average pressure per unit indentation area is measured. Due to the large contact area of the indenter, it is less affected by the distribution of fillers, thus more accurately reflecting the true hardness of filled plastics.

Shore hardness: It relies on the pressure of a standard spring to press a specially shaped indentor into the sample, converting the penetration depth into a hardness value. Due to the sharpness of the indentor, whether the tip contacts the filler or the plastic substrate will directly affect the result, making the testing accuracy for filled systems slightly inferior.

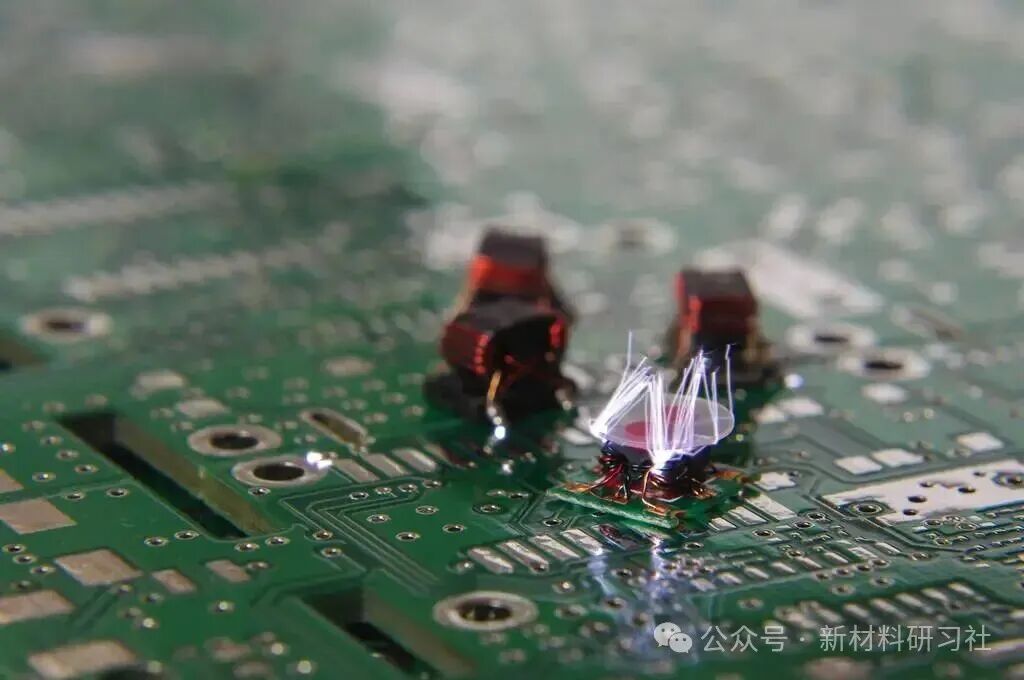

2. Friction Performance

When plastics are used in dynamic sealing, wear-resistant components, and other scenarios, the coefficient of friction and wear resistance are key indicators, and fillers are the core variable for regulating these two properties.

The impact of granularity and filling amount

When the filler particle size is large and the filling amount is small, the surface of the product will be uneven, and the friction coefficient will increase accordingly.

When the filler particle size is fine and the filling amount is sufficient, it can effectively control polymer shrinkage, making the surface of the product smoother, thereby reducing the friction coefficient.

The differential role of filler types

Low-friction fillers: Polytetrafluoroethylene powder, molybdenum disulfide, graphite, etc., have low intrinsic friction coefficients and can directly reduce surface friction resistance when added.

High-hardness fillers: Quartz sand, glass beads, and other fillers with higher hardness may wear processing equipment (such as screws and mold cavities), but can significantly enhance the wear resistance of plastics. For example, adding glass beads to ultra-high molecular weight polyethylene sheets can reduce the wear rate and increase wear resistance by more than 30%.

3. Thermal Performance

The basic heat resistance of filled plastics depends on the matrix resin: for amorphous polymers, it depends on the glass transition temperature, while for highly crystalline polymers, it depends on the melting point. The addition of fillers can further optimize three key thermal performance indicators.

Significant increase in heat distortion temperature.

The heat distortion temperature is an indicator of a material's resistance to deformation at high temperatures. Fillers can enhance the elastic modulus and viscosity of the system, so the heat distortion temperature of filled plastics is much higher than that of pure polymers. A typical example is talc or glass fiber-filled polypropylene, where the heat distortion temperature can exceed 130°C when the filler mass fraction reaches 20%.

The thermal expansion coefficient is reduced, and the shrinkage rate is controllable.

The thermal expansion coefficient of the plastic matrix is much higher than that of the inorganic filler. After compounding the two, the thermal expansion coefficient of the filled plastic significantly decreases, leading to a reduction in molding shrinkage and a substantial improvement in product dimensional accuracy. However, it is important to note that during the cooling process, the filler and matrix may shrink inconsistently, resulting in residual stress that could cause product distortion and warping. The uniform dispersion of modified fillers can effectively mitigate this issue.

Specific heat capacity and thermal conductivity optimize processing efficiency.

The thermal conductivity of fillers is generally higher than that of pure resin. After filling, the thermal conductivity of the material is enhanced, allowing for faster heat transfer during mixing, thermoforming, cooling, and other processing stages. This can shorten the processing cycle and improve production efficiency.

Section 4: Optical Performance

Optical functional fillers are the core components that impart plastics with special optical properties. Currently, the main application directions are divided into two categories:

Reflection and scattering of light functions

Glass beads (especially high refractive index glass beads) are commonly used as light diffusing fillers. When added, plastics can be used for land and water traffic signs, as well as for products like automotive coatings and buttons, enhancing recognition through the light reflection effect. Additionally, specially treated titanium dioxide, mica particles, aluminum foil, and other fillers can produce unique colors through Rayleigh scattering or interference effects, making them suitable for decorative applications.

Far-infrared radiation function

Inorganic fillers such as zirconia, alumina, titanium dioxide, and magnesium oxide can absorb strong infrared radiation at 1000 cm⁻¹. Polymer films and sheets with these fillers can be used in agricultural films (to promote plant growth and fruit ripening), alcohol fermentation, and human warmth, among other applications, offering broad prospects for development.

V. Electrical Performance

Electrostatic accumulation can lead to safety accidents or interfere with the operation of electronic devices. Fill modification is an effective solution to the anti-static problem of plastics, and it can achieve a permanent anti-static effect (as opposed to easily migratable organic anti-static agents).

Core conductive filler and mechanism of action

Metal powders: Silver powder, copper powder, etc., are efficient conductive fillers that need to reach a critical volume fraction to form conductive pathways. For instance, when silver powder is filled into phenolic plastic, at a volume fraction of 40%, silver particles form an "infinitely long particle contact chain," and the system's resistance drops to its lowest.

Carbon black/graphite: A more cost-effective conductive filler. When the mass fraction of carbon black exceeds 20%, the particle spacing is reduced, forming a mesh-like channel for electron flow. A small amount of carbon black also has additional functions such as coloring, anti-ultraviolet aging, and regulating the reaction of thermosetting molding compounds.

Industry Application Standards

In certain special scenarios, there are specific requirements for the conductivity of plastics, such as plastic products used in coal mines, where the surface resistance needs to be less than 3×10⁸Ω. The key technology to meet this standard is the filling of conductive fillers.

6. Magnetic Properties

Magnetic plastics combine the ease of processing of plastics with the functional characteristics of magnetic materials, allowing for the creation of products with complex shapes and fine dimensions. Currently, commercialized magnetic plastics are mainly composite types (structural magnetic plastics have not yet been widely applied).

Two types of mainstream magnetic fillers

Ferrite magnetic powders: such as BaO・6Fe₂O₃ and SrO・6Fe₂O₃, can be used to prepare isotropic or anisotropic magnetic plastics. Compared to sintered magnets, they are lightweight, flexible, have minimal molding shrinkage, can incorporate inserts, allow for continuous molding, and offer excellent chemical stability.

Rare earth magnetic powders: such as SmCo₅ types and Sm₂(Co, Fe, Cu, M)₁₇ types, can only be used to prepare anisotropic magnetic plastics. Although their magnetic and heat resistance properties are slightly inferior to sintered rare earth cobalt magnets, their forming processability and mechanical performance have significant advantages, making them more suitable for the miniaturization and lightweighting trends in electronic components.

Key Factors Affecting Magnetic Strength

The magnetic force of magnetic plastics mainly depends on the amount of magnetic filler added, which is typically between 30% and 90%. The higher the proportion, the stronger the magnetic force. In addition, the crystalline form and orientation of the filler are also crucial. Fillers with uniform crystal shapes and good orientation can significantly enhance the material's magnetic field strength.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories