The High-Value Path of Recycled Plastics in 2025: An Analysis of 5 Major Innovation Highlights!

Under the dual pressures of global "dual carbon" goals and plastic pollution management, the recycled plastic industry is undergoing a "high-value" revolution. The application boundaries of traditional low-end recycled materials are being continuously broken through, from daily chemical packaging to automotive parts, from electronic products to high-end textile fabrics. Recycled plastics are redefining the value logic of the circular economy through technological innovation and design empowerment. The following five innovative directions are leading the industry towards a more advanced sustainable development future.

Recycled Plastic and Aesthetic Design

Breakthrough application scenarios and reshape value logic.

The "high-value" of recycled plastics lies not only in performance enhancement but also in meeting the demands of the high-end market through the integration of aesthetic design and technology.

-

Covestro's CMF solutions: Through big data analysis and consumer research, unique visual and tactile designs for recycled plastics are developed to help brands convey their environmental理念. For example, its recycled plastic products have been used in structural components for high-end consumer goods, featuring a tensile strength of 150MPa and an impact resistance of 20KJ/㎡.

-

Arkema's bio-based fabric: An outdoor apparel fabric made from 100% bio-based Rilsan® PA11, which is not only recyclable but also quickly wicks moisture, is abrasion-resistant, and water-repellent, making it a new favorite among luxury brands.

-

R-Mo Environmental Protection Food Grade R-PP: Breaking through the recycling barriers of polyolefins, with transparency and odor indicators approaching those of virgin materials, achieving over 80% carbon reduction, and already used in high-end applications such as toys and automobiles, with a penetration rate exceeding 50%.

Industry Value: Recycled plastics have evolved from "low-cost substitutes" to "brand premium carriers," driving the circular economy from a cost-oriented approach to a value-driven one.

Chemical Recycling Process Innovation:

Break through the bottleneck of high energy consumption and achieve large-scale breakthroughs.

-

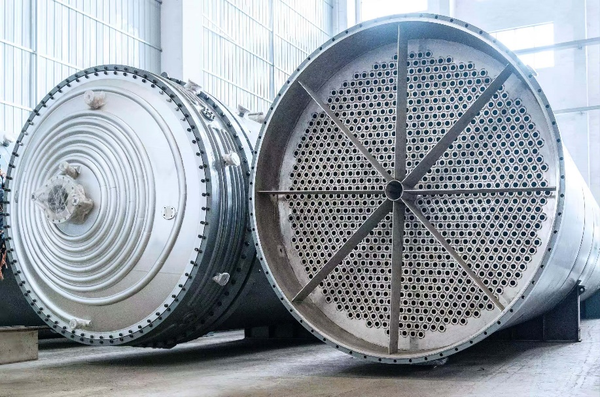

Nippon Steel's twin-screw extruder: It continuously decomposes plastics through screw shear heat, capable of processing various raw materials such as film scraps, achieving a monomer recovery purity of up to 99%, realizing a closed-loop cycle for upstream and downstream.

-

Wanrong Technology's pyrolysis equipment: Utilizing flexible sealing and ultra-low emission technology, it converts mixed waste plastics into pyrolysis oil, gas, and carbon. The patented technology is globally covered and has been put into production in multiple countries.

-

Donggeng Chemical Cyclone Crystallizer: Purifies high-purity materials with 99.999% purity at an ultra-low energy consumption of 230kg steam/ton, capable of continuous large-scale production with a single unit of equipment.

Industry breakthrough: Chemical recycling efficiency improved by over 30%, operating costs reduced by 50%, and the industrialization process accelerated.

Polylactic Acid (PLA) Closed-loop Recycling:

Cracking the "Recycling Dilemma" of Bio-based Materials

PLA is biodegradable, but the lack of a recycling system at the back end has led to controversies over "pseudo-environmentalism." Guanghua Weiye's "X-type" closed-loop technology offers a new perspective.

-

Low-carbon循环: Using recycled materials to produce PLA reduces carbon emissions by 60% compared to virgin materials, promoting the true realization of "cradle to cradle" for bio-based materials.

Biological enzyme method for PET recycling.

Room temperature depolymerization, infinite recycling

The biological enzyme technology of Yuan Tian Biotechnology has ushered PET recycling into an era of "gentle and efficient."

-

Disruptive Technology: PET degrading enzymes modified by genetic engineering can depolymerize waste materials such as polyester and bottle flakes into monomers at room temperature and pressure, and then re-polymerize them into food-grade rbPET.

-

Infinite循环: Recycled PET can be reused multiple times in fields such as optical devices and textile fibers, with zero performance loss in the recycling process.

Industry significance: The energy consumption of the biological enzyme method is only 1/3 of that of the traditional chemical method, and there are no pollution emissions, making it a promising mainstream path for PET recycling.

Mechanical Recycling Upgrade

Mechanical recycling breaks through the bottleneck of performance degradation through intelligent and refined transformation.

-

Dual sorting system: 0.375mm ultra-clear CCD camera, 1mm metal detection accuracy, capable of sorting over 40 types of polymers, with an impurity removal rate exceeding 99%.

Conclusion: High-value recycled plastics are defining the materials of the future.

From "waste" to "fine products," the five major innovation directions of recycled plastics not only provide technical support for environmental protection but also open up a high-end application market worth hundreds of billions. In the future, with policy-driven initiatives and the explosive demand for green consumption, those who can seize the high ground of value-added technology will lead the next decade in the wave of the circular economy.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track