Abstract:To investigate the effect of the length distribution of short glass fibers (sGF) on the properties of melamine cyanurate/nylon 6 (MCA/PA6) composites and to prepare composites that can stably pass the 960 ℃ glow wire flammability test, a series of MCA/sGF/PA6 composites with different sGF length distributions were prepared by adjusting the feeding position of sGF in a twin-screw extruder. The mechanical properties, melt flow rate, vertical burning, and glow wire flammability of these composites were characterized and tested. The results showed that as the side feeding amount of sGF decreased and the main feeding amount increased, the average length of sGF decreased from 405.0 μm to 175.7 μm. Meanwhile, the tensile strength of the MCA/sGF/PA6 composites decreased from 142.4 MPa to 99.3 MPa, the flexural strength decreased from 202.9 MPa to 164.3 MPa, the flexural modulus decreased from 7,035.0 MPa to 5,773.1 MPa, the notched impact strength decreased from 9.9 kJ/m2 to 6.5 kJ/m2, the unnotched impact strength decreased from 61.9 kJ/m2 to 48.0 kJ/m2, and the melt flow rate increased from 16.7 g/10 min to 22.8 g/10 min. In terms of flame retardancy tests, the total afterflame time in vertical burning decreased from 16.5 s to 1.9 s, and the burning time of the 960 ℃ glow wire decreased from 90 s to 35.4 s. When the side feeding amount of sGF was reduced to below 15 parts, the vertical burning rating of MCA/sGF/PA6 composites could reach V-2; when the side feeding amount of sGF was reduced to below 5 parts, the composites could stably pass the 960 ℃ glow wire flammability test. Based on the "candlewick effect" of sGF, the control of sGF length distribution and glow wire burning time was achieved through the melt extrusion process.

Keywords:Chopped glass fibers; Nylon 6; Melamine cyanurate; Glow wire flammability; Candlewick effect; Mechanical properties

Nylon 6 (PA6) has become an important engineering material due to its excellent thermal performance, mechanical properties, and processing characteristics. However, its inherent flammability, water absorption, and dimensional stability severely limit its application in electronic and electrical fields such as connectors and circuit breakers [1-3]. Some circuit breaker applications require the PA6 material to achieve a glow wire flammability index (GWFI) of 960 °C and to have halogen-free, low-smoke, low-toxicity, and good mechanical properties [4-5]. In response, researchers have proposed modifying PA6 by introducing eco-friendly melamine cyanurate (MCA) flame retardants and short glass fibers (sGF) to impart flame retardancy, low water absorption, and high strength to PA6 [6-10]. However, during the combustion process, the sGF in the PA6 matrix can cause a "wick effect" [10], where the exposed sGF, due to its high thermal conductivity, becomes a fast channel for heat transfer to the nylon. Meanwhile, the molten nylon is continuously transported to the combustion zone along the fiber surface by capillary action. This synergistic effect of heat conduction and fuel transport significantly promotes the spread and maintenance of the flame, thereby greatly weakening the isolation effect of MCA in the gas phase [11]. Therefore, to explore the effect of sGF length distribution on the "wick effect" of MCA/sGF/PA6 composites, the author adopted a multi-stage feeding strategy using a twin-screw extruder, adjusting the length distribution of sGF in the MCA/sGF/PA6 composites by changing the feeding position of sGF (combining main feeding and side feeding). The performance of the composites was tested and characterized using a universal testing machine, a simply supported beam impact testing machine, a glow wire testing instrument, and a horizontal and vertical burning tester. Furthermore, the mechanism of the effect of sGF length distribution changes on the mechanical, thermal, and combustion properties of MCA/sGF/PA6 composites was discussed, providing theoretical and data references for developing glass fiber-reinforced PA6 composites with excellent flame-retardant properties.

PA6: J2400, Hangzhou Juheshun Special Materials Technology Co., Ltd.

sGF: ECS10-03-568H, chopped length 3 mm, China Jushi Co., Ltd.

Antioxidants: 1010 and 168, Jiangsu Jiyi New Material Co., Ltd.

Ethylene Bis Stearamide (EBS): Shanghai Jinghong Chemical Technology Co., Ltd.

Melamine cyanurate (MCA-L): Shouguang Weidong Chemical Co., Ltd.

1.2 Main Equipment and Instruments

Electric Heating Blast Drying Oven: GR-GZ9018A, Guangzhou GRR Instruments Co., Ltd.

Twin-screw extruder: STS35 Mc11Coperion (Nanjing) Machinery Co., Ltd.

Loss-in-weight feeder: NX-S50D, Kubota Corporation, Japan.

Injection Molding Machine: MA600Ⅱ/130, Haitian International Holdings Limited.

Simply supported beam impact testing machine: HIT-2492, Chengde Jinjian Testing Instrument Co., Ltd.

Universal Testing Machine: 5966-10KN, INSTRON Corporation, USA;

Melt Flow Rate (MFR) Instrument: MFI-2322H, Chengde Jinjian Testing Instrument Co., Ltd.

Horizontal Vertical Burning Tester: SH5312, Guangzhou Xinhao Electronic Equipment Co., Ltd.

Glow Wire Tester: KS-51BS, Shanghai Jinsen Testing Equipment Co., Ltd.

Box-type resistance furnace: SX2-4-10, Shanghai Jinping Instrument Co., Ltd.

Scanning Electron Microscope (SEM): TM3030, Hitachi High-Technologies Corporation.

Thermogravimetric (TG) Analyzer: TG 209 F1, NETZSCH Company, Germany.

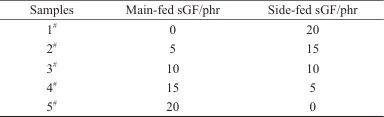

PA6 pellets and MCA are placed in a 120 ℃ oven for drying for 3 hours. After cooling, PA6, MCA, sGF, and other raw materials are weighed according to the formulation, where the main feeding formulation consists of 69 parts PA6, 10 parts flame retardant MCA, 0.6 parts lubricant EBS, 0.4 parts antioxidant 1010/168 (mass ratio 3:1), and a total of 20 parts sGF, with the main feed amount and side feed amount of sGF shown in Table 1. First, the main feed raw materials are manually mixed in a 30 cm×45 cm polyethylene bag. Then, the materials are fed into a twin-screw extruder for extrusion granulation via a loss-in-weight feeder with main and side feeding according to the proportions, as shown in Figure 1. The heating temperature of the twin-screw extruder is set between 200-250 ℃, with the die head at 245 ℃; the main screw speed is set at 350 r/min, with an output of 50 kg/h. Finally, the extruded MCA/sGF/PA6 composite material is placed in a 120 ℃ oven for drying for 4 hours and then processed into test specimens using an injection molding machine.

Table 1 Main-fed and side-fed dosage of sGF

Fig. 1 Schematic diagram of the main/side feeding mode in a twin-screw extruder

The injection-molded specimens are conditioned for 24 hours under the conditions of (23±2) ℃ and relative humidity of (50±5)% before testing.

(1) Tensile strength was tested according to GB/T 1040.2-2022 with a tensile rate of 10 mm/min; flexural strength was tested according to GB/T 9341-2008; impact performance was tested according to GB/T 1043.1-2008.

The flame retardant performance is tested according to GB/T 2408-2021, with a specimen thickness of 1.6 mm, testing 5 specimens each.

(3) The GWFI test is conducted according to GB/T 5169.11-2017, with a sample thickness of 2 mm, and three specimens are tested for each sample.

(4) MFR is tested according to GB/T 3682.1-2018, with test conditions of 250 ℃/2.16 kg.

(5) TG analysis was conducted in accordance with GB/T 33047.1-2016.

(6) Measurement of residual length of sGF: Cut an injection-molded bending specimen weighing approximately 2 g and incinerate it in a muffle furnace at 750 ℃ for 10 minutes. After cooling, place the residual sGF in anhydrous ethanol and disperse it by shaking. Quickly transfer the dispersed sGF onto an SEM sample holder and allow the solvent to evaporate completely. Use SEM to observe the residue, and then measure the remaining length of the sGF using analysis software. sGF shorter than 50 μm is not counted. Each group consists of 300 samples.

2.1 Analysis of sGF Length Distribution and Mechanical Properties under Different Feeding Processes

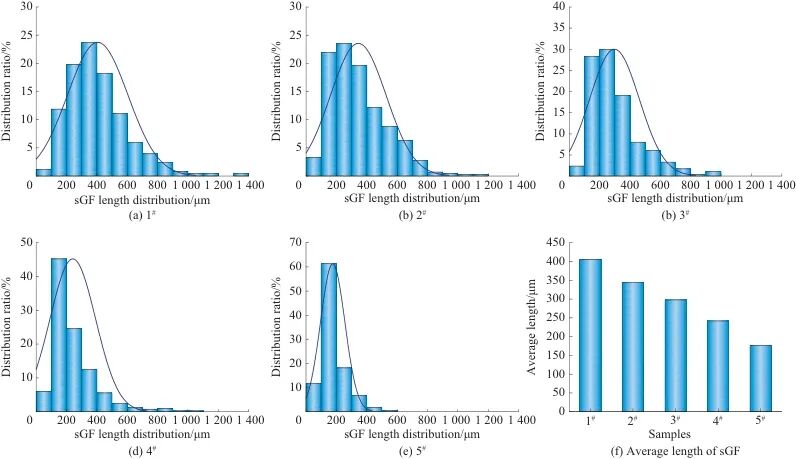

By adjusting the feeding ratio of the main/side feeding of sGF in a twin-screw extruder, MCA/sGF/PA6 composites with different sGF length distributions were prepared. The statistical results of the sGF length distribution in the corresponding composites are shown in Figure 2. From the statistical results of Figures 2a to 2e, it can be seen that 1#The length of sGF in the sample is mainly distributed between 200-500 μm.#

#The length of sGF in the sample is mainly distributed between 100 to 400 μm.#The length of sGF in the samples is mainly distributed between 100~300 μm.#The length of sGF in the sample is mainly distributed between 100 to 200 μm. As can be seen from Figure 2f, 1#~5#The average length of the samples decreased from 405.0 μm to 175.7 μm. This is because the sGF receives a longer screw shear distance when fed from the main inlet, and the presence of unplasticized PA6 particles at the main feeding port synergizes with the screw to exert stronger shear forces on the sGF. In contrast, when the sGF is fed from the side at the fifth barrel section, the screw shear distance is relatively shorter, and the already molten and plasticized PA6 resin provides some protective effect on the sGF. Therefore, the shear effect on the sGF is much greater when fed from the main inlet compared to side feeding, resulting in a gradual decrease in the average length of the sGF as the main feeding amount increases.

Figure 2 Residual length of sGF in MCA/sGF/PA6 composites

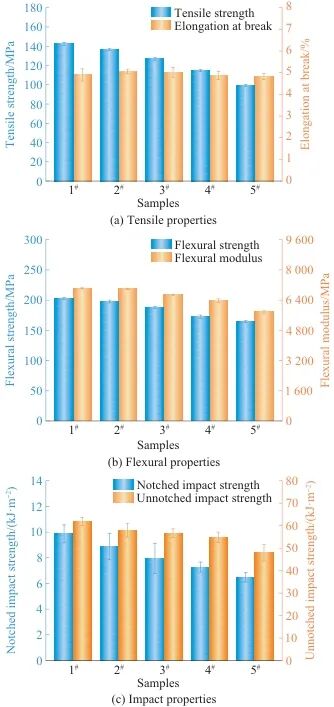

The mechanical properties test results of MCA/sGF/PA6 composites are shown in Figure 3. According to the test data, as the side feeding amount of sGF decreases and the main feeding amount increases, the elongation at break initially shows an increasing trend and then decreases, but the overall change is not significant. The reason for this phenomenon may be that longer sGF can form a good network structure in the resin and have better interaction with the resin. At this point, the higher the sGF content, the more obvious the decrease in the molecular chain movement ability, leading to a further decrease in elongation at break.[12]When the side-fed sGF amount is 5 parts, the composite system is dominated by 15 parts of longer sGF, and the reduction in the content of longer sGF leads to an increase in the mobility of molecular chains, thereby enhancing the tensile strain of the composite. When the side-fed sGF amount increases to 10 parts or more, more shorter sGF in the resin system finds it difficult to form a network structure, and it easily causes defects between the longer sGF and the PA6 resin, which in turn leads to a decrease in the tensile strain of the composite. This trend is also consistent with Ferreira et al.[13]The reported research results are similar. However, other mechanical properties of the composite material show an overall downward trend. The tensile strength decreased from 142.4 MPa to 99.3 MPa, the flexural strength decreased from 202.9 MPa to 164.3 MPa, the flexural modulus decreased from 7,035.0 MPa to 5,773.1 MPa, and the notched impact strength decreased from 9.9 kJ/m.2Reduced to 6.5 kJ/m2The unnotched impact strength is 61.9 kJ/m.2Reduced to 48.0 kJ/m2As the average length of sGF gradually shortens, the network structure formed by sGF deteriorates, reducing the overall viscous force exerted on PA6 resin. Consequently, stress cannot be effectively transferred to the sGF, diminishing its capacity to bear stress, which in turn leads to a gradual decline in the tensile, bending, and impact strength of the composite material.[14-15]。

Figure 3 Mechanical performance of MCA/sGF/PA6 composites

2.2 Thermal Performance Analysis of MCA/sGF/PA6 Composites

The MFR test results of MCA/sGF/PA6 composites are shown in Table 2. As can be seen from Table 2, with the decrease of the side feeding amount of sGF and the increase of the main feeding amount, the melt flow rate of the composites gradually increases, with MFR increasing from 16.7 g/10 min to 22.8 g/10 min. This is because the average length of sGF becomes shorter, leading to a gradual decrease in the intermolecular friction of the composite melt.[16]。

Table 2 MFR of MCA/sGF/PA6 composites

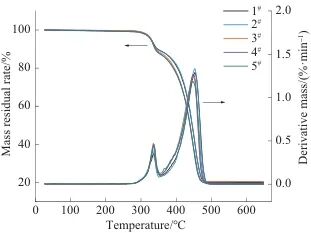

Figure 4 shows the TG and DTG curves of the MCA/sGF/PA6 composite. According to the TG analysis results in Figure 4, the MCA/GF/PA6 composite system exhibits a significant weight loss peak in the range of 290-350 ℃, primarily due to the premature decomposition of MCA. During this stage, MCA begins to decompose into melamine, cyanuric acid, water, carbon dioxide, and ammonia gas.[7,17]The decomposition of MCA can carry away a large amount of heat, and the non-flammable gases have a certain diluting effect on the oxygen in the air, giving the material flame retardant properties.[2,11]From the TG analysis data results in Table 3, 1#~5#Temperature at which 50% mass loss occurs in composite materials due to thermal degradation.T50Temperature of DTG peak 2Tp2There is a downward trend, which may be because the average length of sGF becomes shorter, reducing the thermal stability of the composite material.[18]This causes the decomposition rate of the composite material to accelerate at temperatures above 340 ℃; and the peak 1 temperature of the DTG (Differential Thermogravimetry)...Tp1There is an upward trend, which may be because during the melt extrusion process, the higher content of longer sGF in the composite material is more likely to increase the internal friction of the melt, thereby generating higher shear heat.[19]MCA underwent slight decomposition in the twin-screw extruder.

Fig. 4 TG and DTG curves of MCA/sGF/PA6 composites

Table 3 TG Test Data of MCA/sGF/PA6 Composites

Notes:T5 is temperature at 5% mass loss;T50 is temperature at 50% mass loss;Tp1 is peak temperature 1 in DTG curves;Tp2 is peak temperature 2 in DTG curves;W600% is residual mass fraction at 600 ℃.

2.3 Analysis of Flame Retardant Properties of MCA/sGF/PA6 Composites

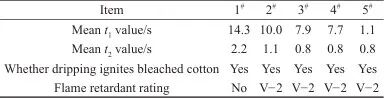

When burning MCA/GF/PA6 composites, longer sGF more readily forms continuous thermal conductive pathways (similar to a candle wick), thereby rapidly transferring heat from the flame zone to the unburned regions inside the material. Simultaneously, sGF can promote the flow of molten polymers and the transport of flammable volatiles through capillary action. The synergistic effect of these two factors offsets the gaseous phase flame retardant effect of MCA, thereby exacerbating the combustion of the PA6 matrix.[20-22]From the test results in Table 4, it can be seen that 1#~5#The vertical burning time of the samples gradually decreases (all exhibit dripping that ignites the absorbent cotton), with the total afterflame time of two burns reducing from 16.5 seconds to 1.9 seconds.#

#When the splint burns, the flame is large, the flame spread rate is relatively fast, and the dripping speed of the melt is relatively slow; in addition, 1#The sample burning time is too long, no flame retardant rating; 2#The burning time of the sample is at the critical value required for the V-2 rating. This is mainly because the longer length of sGF in the composite material plays a stronger "wick" effect, and the overall viscosity of sGF on PA6 is stronger. Additionally, the poor fluidity of the composite material prevents it from dripping promptly during combustion to carry away heat.[2,5]。5#The test results of the samples indicate that when sGF is fully fed, the flame-retardant composite material splines can drip quickly and extinguish. This is mainly because when the sGF length is primarily distributed below 300 μm, the reduction in sGF length distribution makes it difficult for the sGF thermal conduction network structure in the MCA/GF/PA6 composite material to connect effectively. As a result, the efficiency of heat and fuel transfer is reduced, the "wick effect" is suppressed, and the overall viscosity of sGF on PA6 decreases. Additionally, the increased fluidity of the composite material allows the melt to drip quickly and transfer heat.

Tab. 4 Vertical burning test results of MCA/sGF/PA6 composites

Notes:t1 and t2 represent flame duration after the first and second flame application,respectively.

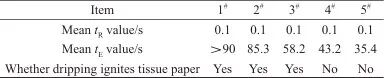

Table 5 shows the results of the 960°C hot wire test for MCA/sGF/PA6 composites. From Table 5, it can be seen that 1#~5#The burning time of the sample gradually decreases, mainly because the reduction in the side feeding amount of sGF leads to a gradual shortening of the sGF length in the composite material. Shorter sGF can significantly weaken the "wick effect" in the composite material, resulting in a noticeable reduction in burning time at 960 ℃ under the glow-wire test. According to the GB/T 5169.11-2017 test standard.[4]The glowing wire application time is 30 seconds, and the sample passes the test only if the afterflame burning time is within 30 seconds after the glowing wire withdrawal and the tissue paper is not ignited by dripping.#

#The sample can pass the 960 ℃ GWFI test. In summary, when up to 5 parts of sGF are fed laterally during the processing of MCA/sGF/PA6 composites, they can consistently pass the 960 ℃ GWFI test.

Tab. 5 Glow-wire test results at 960 ℃ of MCA/sGF/PA6 composites

Notes:tR denotes ignition time of specimen after glow-wire application,while tE represents total flaming duration after ignition.

(1) During the melt mixing process in a twin-screw extruder, as the side feeding amount of sGF decreases and the main feeding amount increases, the average length of sGF decreases from 405.0 μm to 175.7 μm. The mechanical properties of MCA/sGF/PA6 composites show an overall decreasing trend. Although the elongation at break first increases and then decreases, the overall change is not significant.

(2) As the average length of sGF gradually shortens, the intermolecular friction of the MCA/sGF/PA6 composite melt gradually decreases, which leads to an improvement in the flowability of the composite material. When a larger amount of sGF is fed from the side during the extrusion mixing process, higher shear heat is generated, resulting in the decomposition of some of the MCA flame retardant.

(3) As the average length of sGF gradually decreases, the vertical burning time and the 960 ℃ glow-wire burning time of the MCA/sGF/PA6 composites gradually shorten. When the side feeding amount of sGF is reduced to less than 15 parts, the vertical burning rating of the composites can reach V-2 level. When the side feeding amount of sGF is reduced to less than 5 parts, the composites can steadily pass the 960 ℃ glow-wire flammability test.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.