Technology Decoding | Yizhi Mi Seven-Shooting Injection Molding Machine: A Revolutionary Color Revolution, How to Restructure the Boundaries of Intelligent Manufacturing?

Introduction

In the wave of Industry 4.0 and smart manufacturing, the manufacturing industry is rapidly developing towards intelligence, high-end, and greenness. As one of the core equipment in manufacturing, the technological innovation of injection molding machines has always been a focus of industry attention.

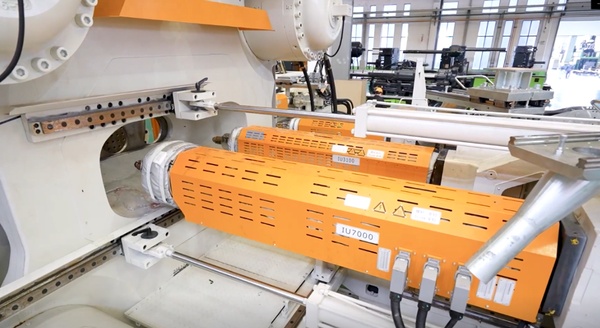

In recent years, with the surge in demand for multi-color injection molded products in industries such as automotive and home appliances, traditional injection molding machines have struggled to meet the requirements of high-end manufacturing. Against this backdrop, the Yizhi Mi UN2400D1M seven-shot injection molding machine (hereinafter referred to as: Yizhi Mi seven-shot injection molding machine) has emerged, promoting the technological upgrade of domestic high-end injection molding machine industry with its innovative multi-shot platform design, high precision control, and intelligent operation, injecting new vitality into the global manufacturing sector.

From "Following" to "Leading", Technological Breakthroughs in Domestic Injection Molding Machines

The launch of the Yizhongmi Qishe injection molding machine marks a leap from "catching up" to "leading" in domestic injection molding machine technology. The key technological breakthroughs of the Qishe injection molding machine in the field of multi-color injection molding have broken the domestic high-end precision injection molding technology's dependence on others, providing more advanced and cost-effective solutions for high-end manufacturing industries such as automotive and home appliances.

The core highlights of the Yizhi Mi seven-shot injection molding machine lie in its multi-shot platform collaborative control technology and high-precision positioning capability, which can bring higher quality and efficiency to the production of complex process products.

The main injection platform of the seven-shot injection molding machine includes three parallel injection units, A, B, and C, supporting single-color injection, and can also be combined with other unit modules to achieve injection molding in up to five colors. This multi-platform coordinated control technology is like conducting a complex symphony, where each injection unit must precisely complete the injection at the correct time, speed, and pressure to ensure the perfect formation of the final product. The flexible and diverse design of the injection platforms also meets the process requirements of different customers, significantly improving production efficiency and shortening delivery times.

In addition, its turntable is controlled by servo technology, which allows for fast speeds and precise positioning, with a repeat accuracy of ±0.005°. This high-precision control technology ensures efficient and accurate multi-station rotation. The turntable's pipeline uses a tank chain synchronous rotation design, effectively reducing wear and leakage, prolonging the machine's lifespan, and lowering maintenance costs. The unique independent temperature control system perfectly integrates with the main unit, allowing for independent operation or parameter setting on the KEBA computer, ensuring the precision and stability of temperature control, thereby enhancing product quality.

Meet high-end manufacturing needs and lead the trend of intelligence.

High-end and intelligent manufacturing are important trends in the future development of global manufacturing. The launch of the seven-shot injection molding machine reflects Yizhi Mi's precise insight into the market and accurate grasp of industry trends.

As a powerful tool for high-end manufacturing, the Yizumi seven-shot injection molding machine achieves precise co-injection of five different materials or colors within the same mold, not only meeting the high strength and high precision requirements of complex components but also greatly enhancing the design freedom and functionality of products. For example, in the automotive sector, it can create headlamp assemblies with integrated soft rubber sealing rings; in the electronics field, it can achieve multi-material insert injection to meet the needs for lightweight and integrated functionality in electronic products; in the medical field, it can produce high-precision and high-cleanliness medical device components.

The IZM seven-shot injection molding machine, equipped with the YiMES intelligent manufacturing execution system, can achieve more intelligent production, such as intelligent scheduling, real-time monitoring and analysis of production data, machine status supervision, and energy consumption management. YIMES, by integrating AI algorithms, can help machines autonomously optimize process parameters and precisely control every production link, ensuring the stability and consistency of product quality. Additionally, it features remote monitoring, parameter adjustment, and predictive maintenance capabilities, significantly enhancing the flexibility and response speed of production, further meeting the demands for intelligent production in high-end manufacturing.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

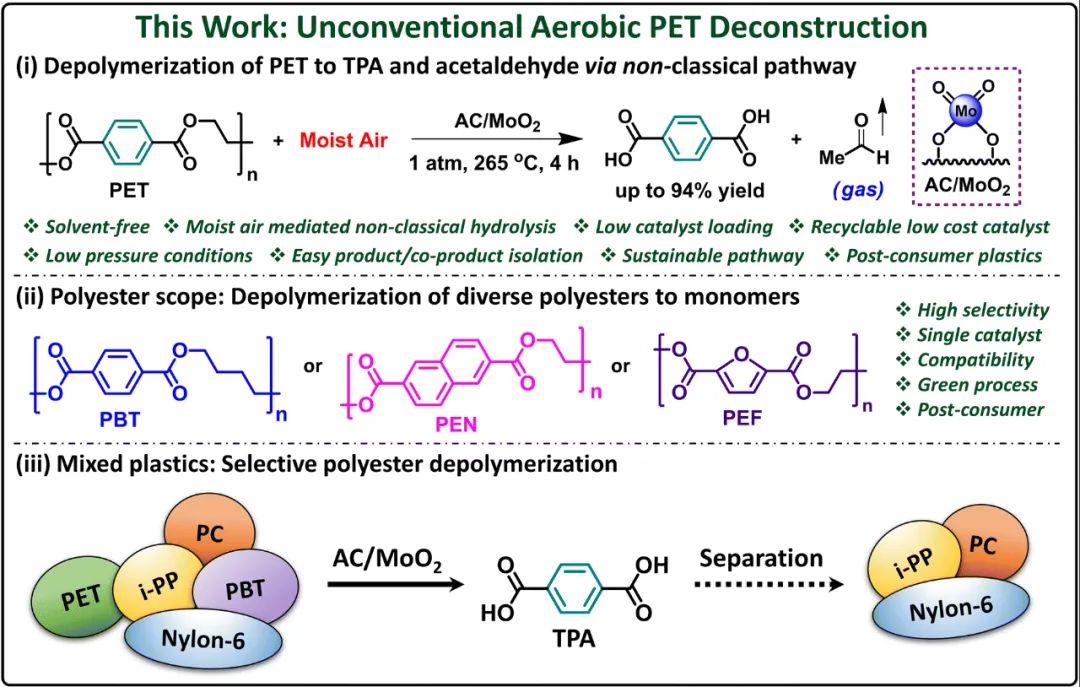

Efficiently Recycle PET Using Air Moisture, with an Efficiency Rate of Up to 94%

-

A press conference with 20 names makes car companies seem like they are writing web novels.

-

"The Strongest" Xiaomi, Lacks "Surprise"

-

【EVA Weekly Outlook】Photovoltaic demand remains robust, EVA maintains a trend of fluctuation and consolidation

-

【Global News】Israel-Iran Conflict Escalates! U.S. ITC Launches Investigation into Ink Cartridges and Components; Harman Introduces New Display Technology