Struggling with shielding effectiveness? conductive filler selection logic every modified plastics r&d engineer must master

With the increasing popularity of electronic devices, electromagnetic interference (EMI) has become a critical issue affecting product electromagnetic compatibility (EMC). While plastic enclosures offer advantages such as lightweight design, low cost, and design freedom, However, due to its "transparency" to electromagnetic waves, it cannot provide intrinsic shielding. 。

This article aims to address a common issue in production. Poor adhesion of shielding coatings, thermal cycling cracking, failure after scratching, and difficulty in balancing modification costs. Pain points, compared to electroless plating, spraying, and conductive compounding, to help you optimize your product design.

In-depth analysis

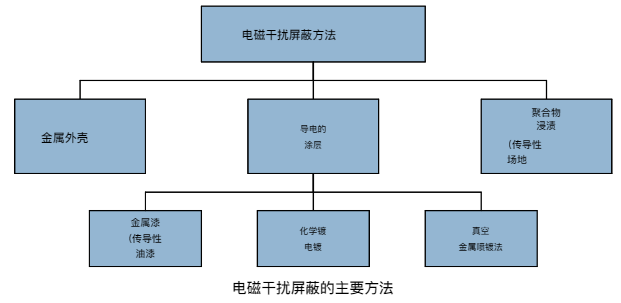

EMI Shielding Solutions for Plastics

1. Question: Why do plastic enclosures need electromagnetic shielding?

Equipment interference All electronic devices emit electromagnetic radiation during operation, which, without effective shielding, can interfere with nearby equipment or sensitive systems such as aircraft.

Self-protection The device also needs to be shielded from external electromagnetic interference to ensure its proper operation.

Material defect Traditional metal housings, while offering shielding, are heavy and difficult to recycle; while plastics solve the weight and cost issues, they fail to block electromagnetic waves.

Regulatory Requirements As the world of wireless communication evolves, legal regulations regarding the shielding performance of new devices are becoming increasingly strict.

2. Reason: Key factors contributing to the failure of the shielding.

The essence of shielding is to create a "Faraday cage." Current failures are mainly due to:

Insufficient coating adhesion Polyolefins, fluoropolymers, and other materials are difficult to bond with conductive coatings and often require pretreatment (etching).

Residue contamination Mold release agents (such as silicone oil) can severely compromise the adhesion of coatings to plastic substrates.

Slot antenna effect Scratches or coating loss due to assembly friction (e.g., at snap-fit joints) can create electromagnetic leakage gaps.

CTE mismatch induced cracking The large difference in the coefficient of thermal expansion between the coating and the plastic makes them extremely prone to cracking and electrical discontinuity during thermal cycling.

Volume rendering artifacts For conductive modified plastics, shielding effectiveness is highly dependent on filler loading, dispersion, and part thickness.

3. Solutions: Comparison of Mainstream Shielding Technologies

Conductive coating solution (establishing a shielding layer on the surface)

Conductive paint spraying Metallic fillers such as silver, copper, or nickel are suspended in a paint layer to form a continuous conductive network. Nickel paint, while scratch-resistant, has slightly lower conductivity.

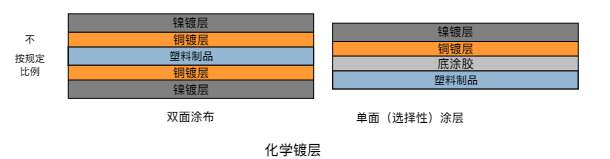

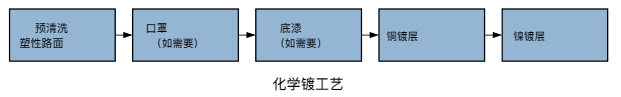

Electroless plating Electroless Plating: Autocatalytic deposition of metal without applied electric current. Typically uses a structure of "3 μm copper layer (conductive) + 1 μm nickel alloy layer (anti-corrosion)".

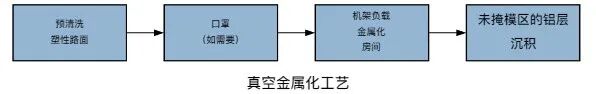

Vacuum aluminizing Deposit an approximately 10-micrometer-thick layer of aluminum in vacuum, offering excellent electrical conductivity and low cost.

02. Conductive Modified Plastics (Bulk Absorption Shielding)

Achieving bulk shielding capability by directly incorporating conductive fibers during plastic modification/compounding.

Augmentation Body Stainless steel fiber, copper fiber, carbon fiber, or nickel-plated carbon fiber.

Core strengths Shielding performance is inherent to the product, scratch and peel resistant, eliminates the need for secondary spraying, and significantly reduces scrap rates.

Process flexibility Suitable for injection molding or extrusion processes, and without complex spray masking requirements, ideal for intricate shape designs.

4. Performance Testing and Cost Trade-offs

Shielding Effectiveness (SE): Measured in decibels (dB), calculated as: dB = 20log(EM) / EM )

Testing Methods Coatings are typically tested for surface resistivity, while conductive plastics require volume resistivity testing. Additionally, the SE value of planar materials should be measured with reference to standards such as ASTM D4935.

Cost Recommendations Conductive modified plastics are suitable for small to medium volumes due to the absence of initial mold and fixture costs; while coating processes become more competitive at extremely high volumes (e.g., over 1 million parts) as fixture amortization costs decrease.

Written in conclusion.

EMI shielding is no longer a single “coating” subject. For high-precision and complexly designed electronic components. Conductive compounded plastics are gradually replacing traditional spraying due to their integrity of "one-time injection molding."

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

New 3D Printing Extrusion System Arrives, May Replace Traditional Extruders, Already Producing Car Bumpers