Single-Screw Extrusion Rate Limited? Adding Screw Cooling Solutions Breaks Through Single-Screw Extrusion Rate Constraints

For a production line with complex downstream processes, a single-screw extruder may due toInsufficient motor torque, screw speed, high discharge temperature, and sudden surge in flow and other limitationsAnd is subject to rate limitations.

For example, many processes are limited by the rate of heat generation and conduction to the solid conveying zone of the screw, leading to excessive screw temperatures. Excessive screw temperatures can cause surging in the extruder flow and result in operation at a lower rate.Screw cooling is a simple method to remove energy and increase the maximum line speed.

Running the extrusion production line at a higher speed is an effective way to reduce costs and increase profitability. Today, we will examine the impact of adding screw cooling on the polycarbonate (PC) extrusion process through a case study.

Solid material conveyingThe key process of single-screw plasticizing extruder.Solid transport depends on the shear stress at the polymer-metal interface. Below the melting (or denitrification) temperature, the shear stress exerted on the solid bed is proportional to the coefficient of dynamic friction.

Generally speaking,The dynamic friction coefficient is a function of temperature, pressure, and the relative speed of polymer friction on the metal surface.At higher temperatures, the shear stress at the polymer-metal interface is governed by a viscous mechanism, and the shear stress depends on the viscosity and velocity gradient in the melt film between the solid and the barrel wall.

If the stress at the interface is not optimal, resulting in non-optimal forces on the solid bed in the conveying zone, poor solid conveying may occur, leading to flow surges and a reduction in rate.

Case Study: PC Extrusion

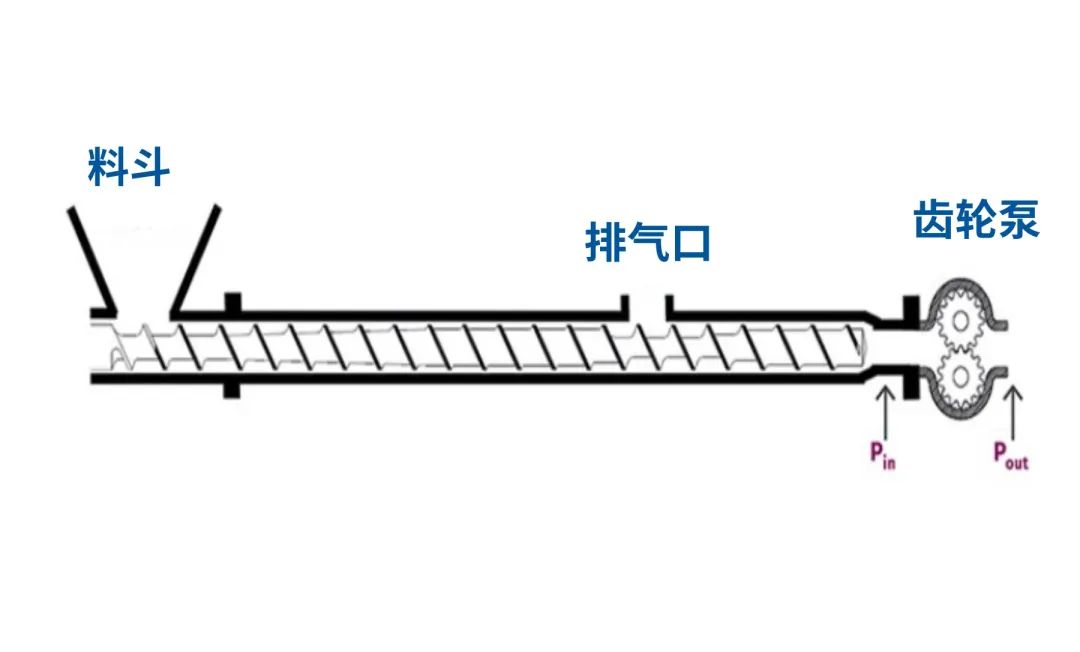

An 8-inch diameter, two-stage, vented extruder is operating with a PC A resin having a melt flow rate (MFR) of 6 g/10 min (300°C, 1.2 kg). A schematic of the process is shown in Figure 1.

The process is unstable, but it can operate at a low rate using fresh pellets. The feed section is eight diameters long, and a cooling hole is drilled at the shank end of the screw, with the diameter being a maximum of 3.5 times the starting point of the screw.

Figure 1: Schematic diagram of the two-stage venting extrusion process of PC resin. Source (all images): MA Spalding

However, the production line is not equipped with screw cooling. The rest of the screw is normal for the PC process. The gear pump is located between the extruder and the die. The controller on the gear pump adjusts the screw speed to maintain the inlet pressure at 700 psi.

The extruder speed is limited to 3,800 pounds per hour for producing acceptable products using fresh pellets. At higher rates and low recycle levels, the process becomes unstable, and the extruder operates at a lower specific rate. The specific rate is simply the rate divided by the screw speed.

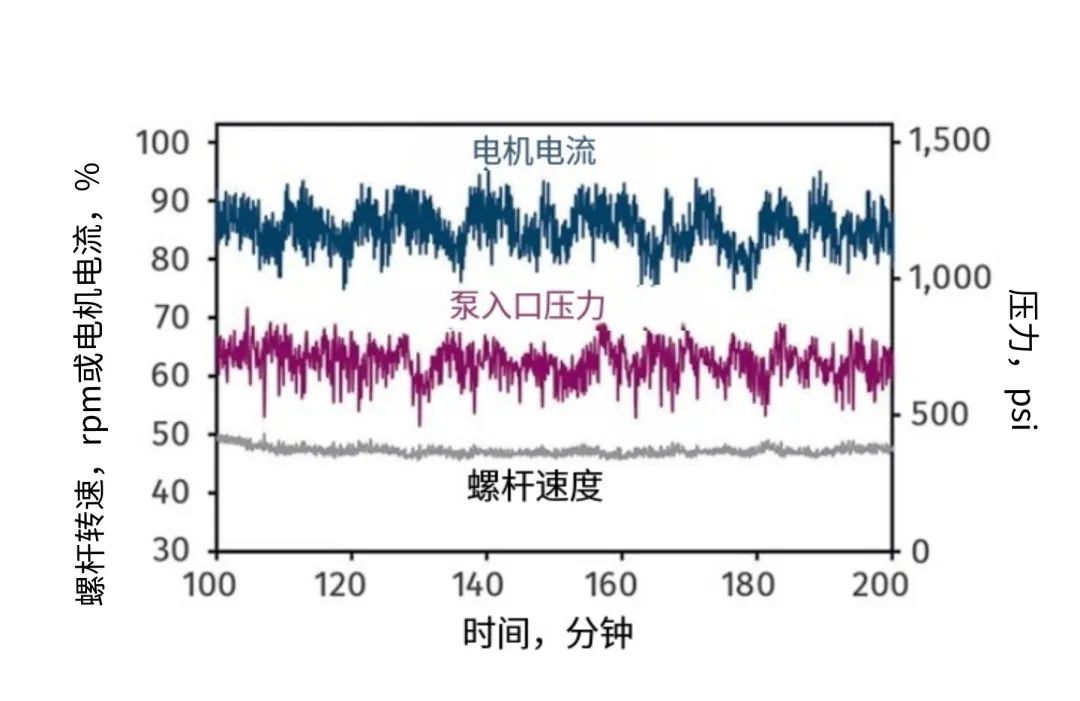

The production line performance shown in Figure 2 indicates a fresh pellet raw material rate of 3,800 lbs/hour, with a ratio rate of 79 lbs/(hour/minute). As illustrated, the oscillation amplitudes of the motor current and discharge pressure exceed expectations. However, the screw speed remains relatively constant, suggesting that the changes in the pump inlet pressure are insufficient to cause the controller to adjust the screw speed.

Figure 2: Flow surges during the extrusion process of PC granules, showing variations in pump inlet pressure and motor current at a rate of 3,800 pounds per hour.

The process data in Figure 2 indicate that the control of the extruder screw speed is not the fundamental cause of the surge.

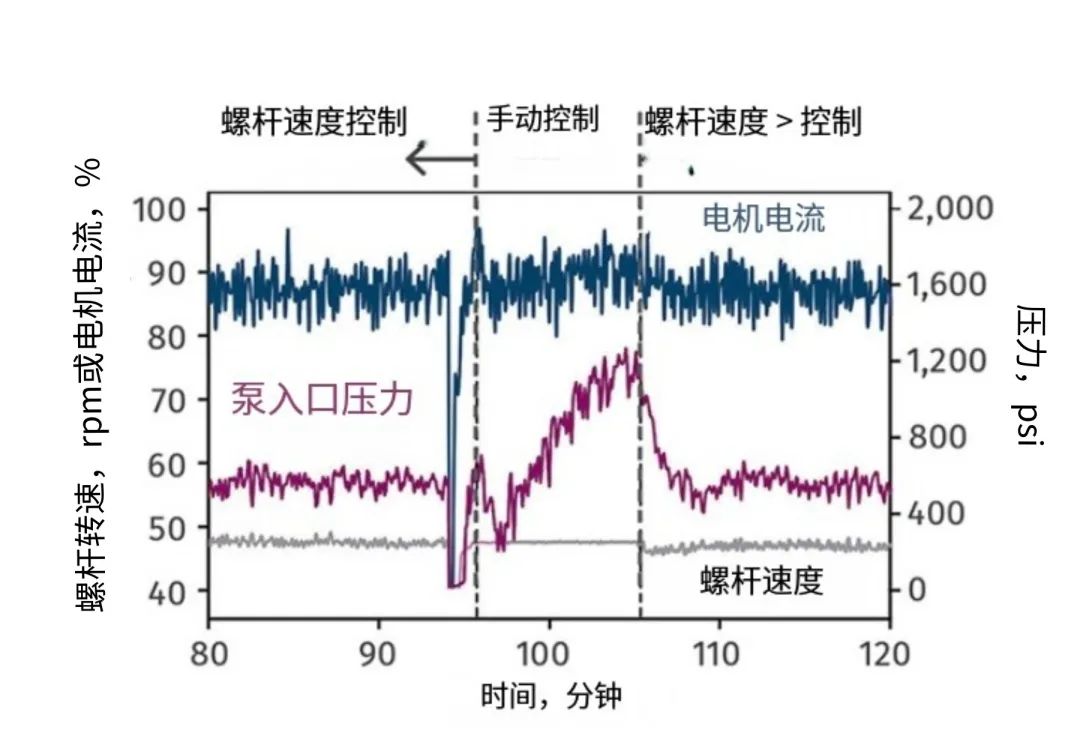

As a simple test, the controller was set to manual mode to collect data at a fixed screw speed for approximately 95 minutes, as shown in Figure 3. There was essentially no change in pump inlet pressure and motor current, confirming that the screw speed controller is not the root cause of surge. However, since the screw speed was slightly higher than the average controlled speed, the inlet pressure increased over time. This simple test should be performed when surge occurs with a gear pump.

Figure 3: The gear pump controller is in manual mode, and the extruder screw speed is constant at 3,800 pounds per hour, demonstrating process stability.

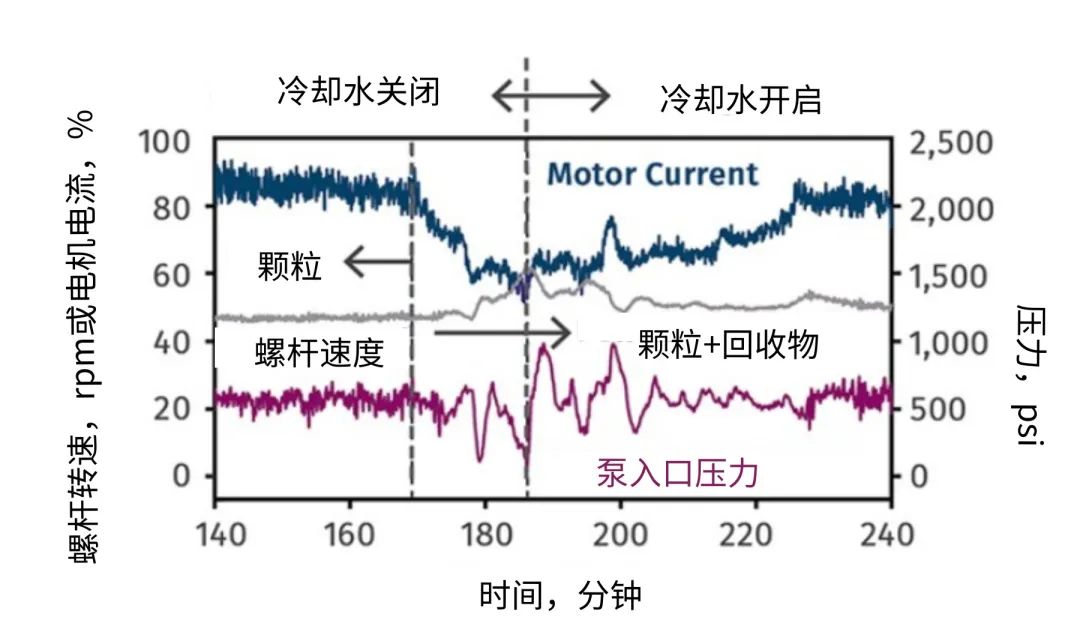

Figure 4: Exhaust pressure and motor current with and without screw cooling calculated at a rate of 3,800 lb/hr.

Approximately 170 minutes later, add low-content recycled resin to the raw materials.

Figure 4 shows process instability when a small amount of recycled resin is added to the extruder at a rate of 3,800 lbs/hr.

Between 140 and 170 minutes, the process remains relatively stable. During this period, the screw cooling is turned off.

At 170 minutes, low-level recycled material was added to the raw material. This addition reduced the bulk density of the raw material and decreased the solid conveying capacity. The motor current decreased, and the screw speed increased, indicating a reduction in specific rate. The inlet pressure of the gear pump was oscillating.

At 188 minutes, the screw cooling is turned on. As shown in Figure 4, the motor current increases slowly, and the screw speed decreases to a normal level. Screw cooling can effectively stabilize the process.

When using screw cooling, for materials containing recycled feedstock, the maximum rate increased from 3,800 lbs/hr to 4,300 lbs/hr, an increase of 13%. Recall that the cooling holes on the screw only extend into the solid conveying zone about 3.5 diameters, but the length of this zone is 8 diameters. The cooling holes should extend to the end of the solid conveying zone. Increasing the length of the cooling holes to eight diameters may allow for higher rates.

The cooling holes on the screw should extend to the end of the feed section, and the cooling tube should extend to within 2 inches of the hole end.

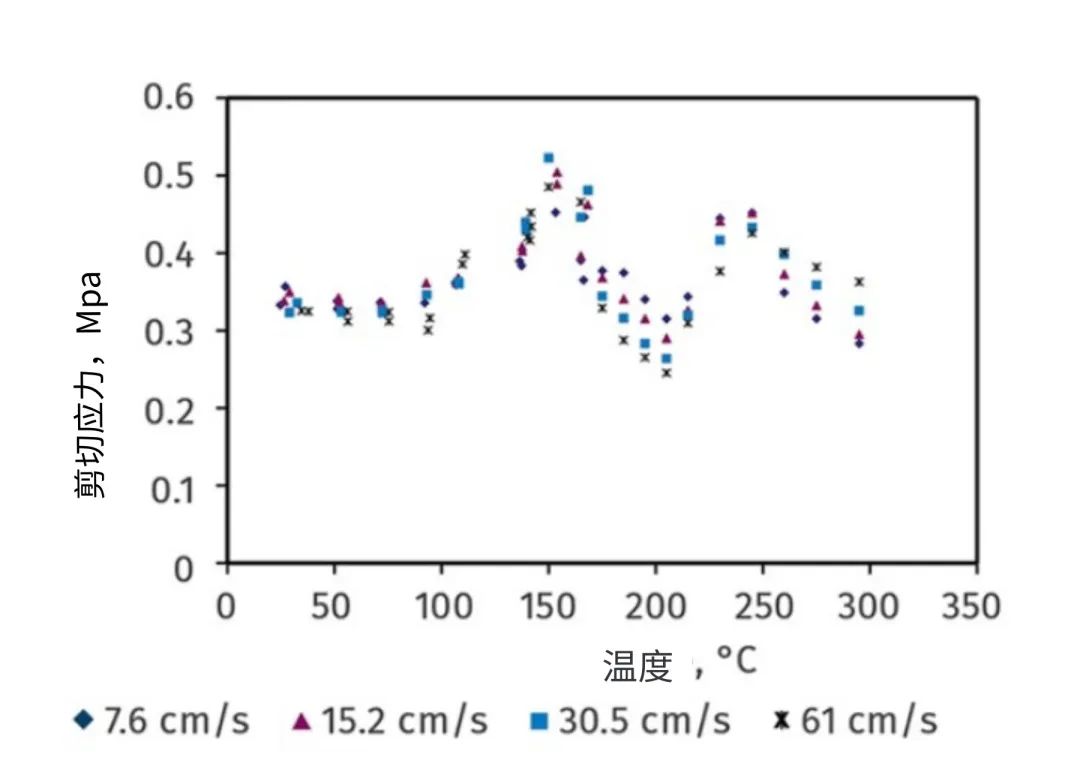

Figure 5 Stress at the interface for conveying solids at 100 psi, as a function of velocity.

Optimal solid conveying occurs when the forward force at the barrel wall is maximized and the drag force at the screw surface is minimized. These forces are proportional to the stress at the interface. The stress at the interface is a function of pressure, sliding velocity, and surface temperature, as shown in Figure 5.

When the surface temperature is below the glass transition temperature (150°C), the force is frictional, whereas at higher temperatures, the force is caused by the resin viscosity. Two maximum peaks appear in the stress, one at 160°C and the other at 250°C. To maximize the forward force using the second peak, the barrel surface temperature needs to be approximately 250°C. To maintain the surface temperature at 250°C, the first barrel zone temperature is usually kept at 300°C. To minimize the deceleration force on the screw surface, the screw temperature should be below 100°C.

In summary,Adding screw cooling provides an additional level of control to the extrusion process and has the potential to increase the rate.The cooling holes on the screw should extend to the end of the feed section, and the cooling tube should extend to within 2 inches of the hole end. If the cooling tube is not properly connected to the screw shank, the connection will eventually leak, causing internal issues.

Often, when water starts to leak, factory personnel will disconnect the screw cooling system. The long-term operation of the cooling system depends on proper connections.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track