Revolution in Shared Intelligence: Researchers Develop Swarm Intelligence Robots

In today's era of rapid advancement in automation technology, collaboration between robots is no longer a science fiction scenario. Imagine this scene: dozens of machines transporting goods in a warehouse without interfering with each other; in a restaurant, robots accurately delivering dishes to designated tables; or in a factory, robot teams dynamically adjusting task distribution based on demand.

(Image source: ieeexplore.ieee.org)

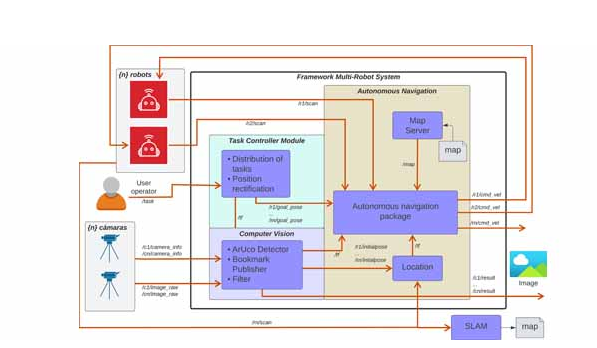

According to foreign media reports, an international research team has developed a new system based on a ROS2-based open-source framework, enabling multiple robots to collaborate in an intelligent, flexible, and safe manner, thereby helping to realize this future vision. The related research results have been published in the journal IEEE Access.

To put theory into practice, researching how robots collaboratively navigate is crucial. The core of robot collaboration lies in their communication capabilities and real-time decision-making mechanisms. This system integrates three key features:

Autonomous Navigation: Each robot uses GPS-like algorithms to calculate the optimal path, but these algorithms have been adaptively optimized for dynamic environments. With tools like GAZEBO, robots can complete training in a virtual environment before being deployed in real-world operations. If unexpected obstacles (such as fallen boxes) are encountered, the system can immediately re-plan the route.

Adaptive behavior: The system uses a dynamic manual of instructions—a "behavior tree." For example, if a robot gets stuck, it will first attempt to turn, then reverse; if the problem remains unsolved, it will request help from the central system. This approach not only prevents collisions but also enables system scalability, expanding from two robots in the laboratory to 20 robots in the factory.

Computer vision and task allocation: Serving as the "eyes" and "brain" of the collaborative system, this technology ensures that robots can accurately locate themselves and execute tasks. The system integrates two technologies: first, ArUco markers (similar to QR codes for robots, which are printed markers used as reference points in the environment); second, distributed cameras. By detecting these markers in real time and performing calculations, the positioning error of each robot can be controlled within 3 centimeters.

The robot seems to carry an internal map that is continuously updated. Another technology is intelligent task allocation, where the system prioritizes assigning the nearest available robot, much like a delivery person choosing the shortest route. When one robot malfunctions, another automatically takes over, ensuring that the task does not stop.

To validate the system, researchers designed complex scenario simulations. In an industrial warehouse scenario, robots need to transport packages between stations marked with ArUco tags while avoiding congestion. In a restaurant scenario, robots must deliver dishes to designated tables and coordinate with each other to avoid collisions in narrow passages. Finally, researchers tested the cooperation of a heterogeneous team (ranging from small robots to robotic arms) in the laboratory setting.

The test results are convincing, with the robot positioning accuracy reaching an average error margin of 2.5 cm. The system demonstrates excellent robustness, as when one robot fails, another can take over its tasks within a few seconds.

Finally, this addresses a key challenge in the field of robotics—scalability. The system works effectively with both 5 and 15 robots and can adapt according to environmental demands. This framework is designed not only for robotics experts.

This open-source system is based on the widely used ROS2 platform, allowing any enterprise to customize it according to their needs. For example, hospitals can program robots to deliver medicines, logistics centers can optimize goods sorting, and even museums can enable autonomous guided tours. In addition, the system reduces reliance on human operators, freeing up human resources from repetitive tasks so they can be allocated to more strategically important work.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track