Plastics Companies Must See! China Reaches 20 Million Charging Piles, Exclusive Roundup of Top Ten Brands, Future Application Directions for Plastics Here

According to data released by the National Energy Administration and cited by Special Plastics Vision on January 21, the total number of electric vehicle charging infrastructure (guns) in China reached 20.092 million by the end of December 2025, a year-on-year increase of 49.7%, breaking the 20 million mark. This data not only demonstrates the vigorous development of China's new energy vehicle industry, but also brings unprecedented opportunities to the charging pile-related industrial chain, especially plastic companies, which have broad application space in the manufacture of various charging pile components. This article will review the top ten new energy vehicle charging pile brands in China and look forward to the future penetration trend of plastics in charging pile components.

Image generated by AI.

The charging pile market is booming, with the top ten brands leading the trend.

Amidst the booming electric vehicle charging station market, a group of brands with strong capabilities and widespread influence has emerged.

TGood Electric As a new infrastructure unicorn company, it stands out in the charging network technology field with its strong shareholder background and professional R&D team, and its "three-network integration" business structure builds a complete ecosystem.

Star Charge Becoming the world's leading charging equipment vendor with a "cloud, pipeline, and device" integrated model, achieving remarkable results in building a comprehensive industry chain ecosystem.

Beijing Energy International As a national high-tech enterprise and a "Little Giant" enterprise specializing in sophisticated and innovative products, our core competitiveness lies in high-power charging equipment, with products boasting global quality standards.

Lv Chong Chong Focusing on the smart charging field, holding a leading position in the electric bicycle charging pile niche market.

Focusing on intelligent charging equipment for electric vehicles, we have built a complete R&D and production system.

Superwings TechnologyAs a professional energy charging equipment manufacturer, we boast a rich product line and strong production capacity.

XINGKE Based in the Central Plains region, focusing on core hardware R&D for charging equipment.

DingDing Smart Possesses full-chain capabilities and extensive business coverage.

BYD Leveraging full-stack in-house development capabilities, the company has built a core competitiveness of "vehicle-charging synergy."

State Grid As a central state-owned enterprise, we are a core pillar for the construction of charging infrastructure in China, playing a leading role in standard setting and network deployment.

These brands each have their own advantages in areas such as technology research and development, market layout, and product quality, and together they have promoted the development of China's charging pile market. For plastic companies, these brands are not only potential important customers, but the development direction and demand changes of their products will also directly affect the application trends of plastics in the charging pile field.

Charging Pile Enclosures: The Mainstream Choice of Plastic Materials

As the external protective component of charging piles, the charging pile housing has extremely high requirements for material performance. It needs to have mechanical strength, electrical insulation, flame retardancy, weather resistance, low-temperature impact resistance, corrosion resistance, and processability. In practical applications, PC/ABS alloys in modified plastics have become common materials for charging pile housings due to their balanced physical and mechanical properties and excellent weather resistance. For example, Tesla uses high flame retardant grade PC/ABS (FR3030), and BMW's i-series electric vehicle charging piles use PC/ABS (T65XF) with high flow performance, which fully reflects the advantages of PC/ABS alloys in the manufacture of charging pile housings.

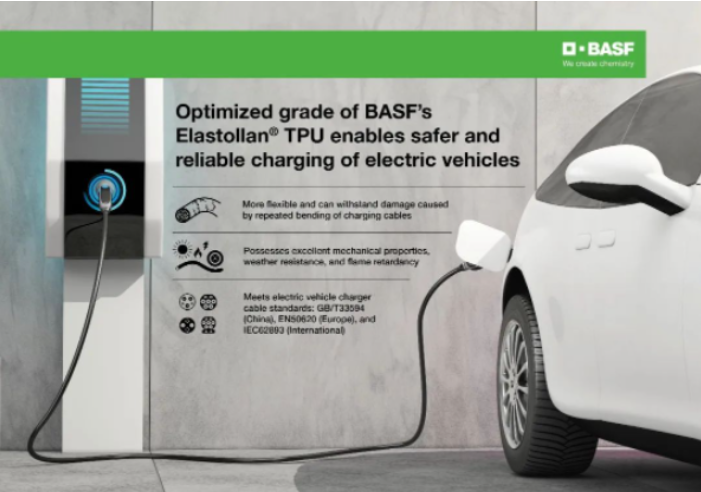

Source: BASF

Besides PC/ABS alloys, halogen-free flame retardant PC materials, ASA, and PC/PBT materials are also used as modified plastics. These materials can be selected according to different application scenarios and personalized needs. For example, adding spray-free technology can achieve different appearance colors. Furthermore, although SMC composite materials have excellent electrical and corrosion resistance, and their mechanical properties are comparable to some metal materials, thermoplastic materials are expected to gradually replace their large-scale application in the future due to the high investment cost of equipment and molds and the difficulty of recycling. This provides a broad market space for plastic companies, which can increase investment in the research and development and production of related plastic materials based on market demand and technological development trends.

Charging Guns and Connection Systems: Diverse Applications of Plastic Materials

The charging gun and connection system, including the charging gun housing and connector, have strict material performance requirements. The charging gun housing needs to have flame retardant properties, electrical insulation, weather resistance, rigidity, and toughness. Halogen-free flame retardant and weather-resistant PC and its alloy materials are common choices. Imported materials such as SABIC's LEXAN™ PC resin and Covestro's Marolon, as well as domestic PC materials, PC/ABS, or PC/PBT materials, are used. Modified PPS materials launched by Suzhou Napan New Material Technology Co., Ltd. are considered more suitable for charging gun applications due to their excellent mechanical properties, high and low temperature resistance, weather resistance and radiation resistance, good insulation and flame retardancy, and excellent processing performance. BASF's Ultramid® polyamide, with its excellent flexibility, chemical resistance, toughness, and aesthetics, is also widely used in charging gun housings and charging gun cable cooling pipes.

Source: Wanlian Technology

Excellent electrical insulation, flame retardancy, heat resistance, and mechanical properties are required for charging connectors, making halogen-free flame-retardant reinforced nylon materials a recommended choice. Plastics companies have abundant material selection and application space in the field of charging guns and connection systems, and can meet the needs of different customers and improve the market competitiveness of products through continuous innovation and optimization of material properties.

Internal Control System Components and Cable Assemblies: Exploring the Potential of Plastic Materials

The components of internal control systems, including power modules, contactors, circuit breakers, and cooling fans, require materials with properties such as halogen-free flame retardancy, good electrical insulation, good dimensional stability, and easy laser marking. Halogen-free flame retardant reinforced PA and PBT materials are generally recommended. Cooling fans require flame retardancy, heat resistance, low noise, and good dynamic balance performance, with flame retardant reinforced PBT or PPE materials being common choices. For cable assemblies, insulation, flame retardancy, weather resistance, crush resistance, and flex resistance are key requirements. Modified plastics are mainly used in the inner and outer sheaths of cables. Halogen-free flame retardant TPE and TPU can be used for the inner sheath, while PVC and halogen-free flame retardant elastomers can be used for the outer sheath. BASF's Elastollan thermoplastic polyurethane (TPU) 1180A10WDM is specifically optimized for fast charging pile charging cables, with a more flexible material that improves the safety and reliability of charging cables.

With the continuous development of charging pile technology and the increasing performance requirements, the material requirements for internal control system components and cable assemblies will become more stringent and diverse. Plastic companies can strengthen cooperation with charging pile manufacturers, gain in-depth understanding of their needs, increase investment in new material research and development and application, explore the potential of plastic materials in these fields, and provide higher-quality material support for the development of the charging pile industry.

The rapid development of China's electric vehicle charging infrastructure presents significant opportunities for plastics companies. Plastics companies have broad applications in various components such as charging pile enclosures, charging guns and connection systems, internal control system components, and cable assemblies. By monitoring the development trends of the top ten charging pile brands and understanding the market's changing demands for charging pile performance and materials, and by continuously innovating and optimizing the performance of plastic materials, plastics companies are expected to gain a foothold in the charging pile market and achieve their own development and growth. At the same time, this will also promote the development of China's charging pile industry towards higher quality, more environmentally friendly, and more efficient directions.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories