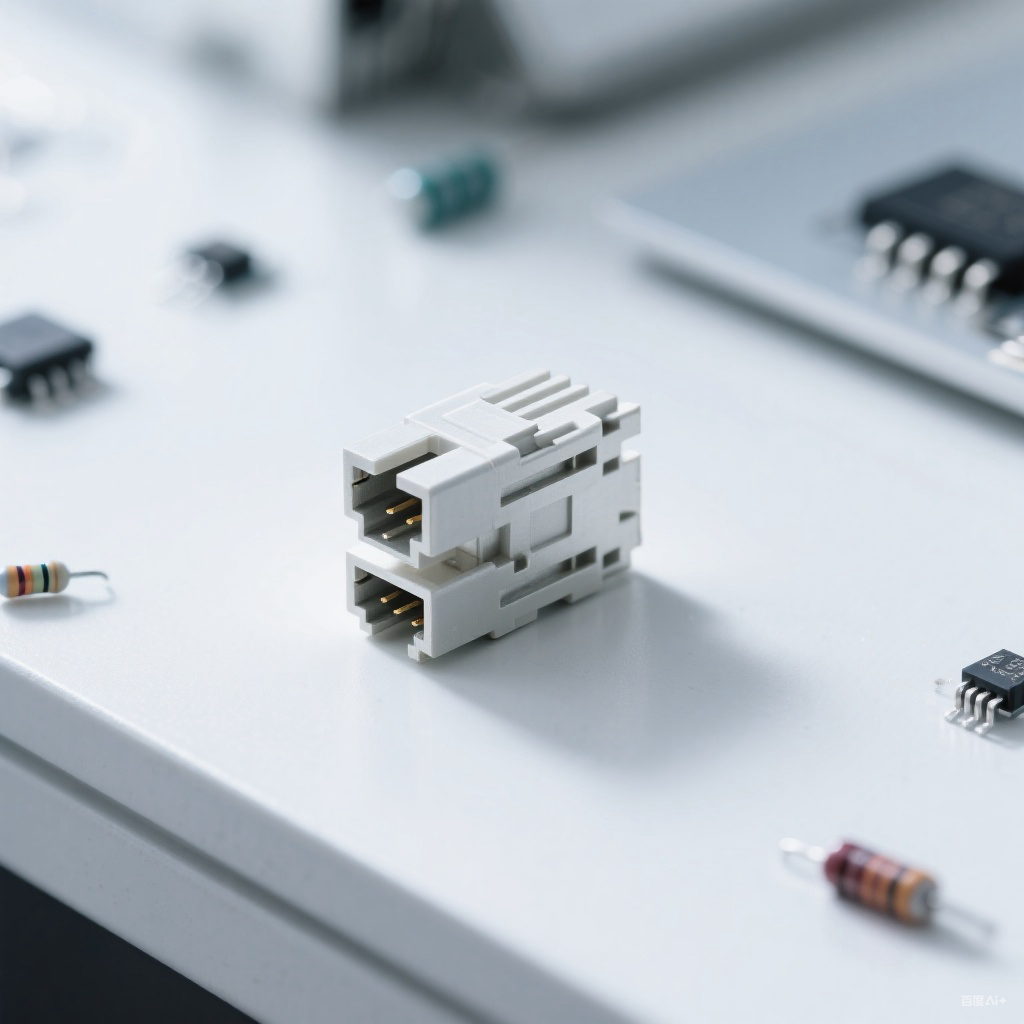

Performance Requirements and Modification Formulations of PA66 for Electronic Connectors

PA66 (Nylon 66) is one of the most widely used engineering plastics in the field of electronic connectors due to its excellent comprehensive properties (mechanical strength, heat resistance, wear resistance, chemical resistance, and ease of processing) and relatively reasonable cost. However, to meet the increasingly stringent performance requirements and complex application environments of electronic connectors, pure PA66 typically needs to be modified.

1. Main Performance Requirements of PA66 for Electronic Connectors

1. Excellent mechanical properties:

High strength and rigidity:Ensure that the connector resists external forces (such as insertion and withdrawal force, crimping force, impact force) during plugging, assembly, and transportation without deformation or breakage, thereby ensuring reliable connection.

Good toughness/impact strength:Resist accidental drops or impacts to prevent brittle fractures, especially in low-temperature environments.

Size stability:Maintain precise dimensions and tolerances to ensure accurate positioning and reliable contact of pins/sockets, preventing poor contact or insertion/extraction difficulties caused by deformation.

2. Excellent heat resistance:

High HDT:Able to withstand the high temperatures of wave soldering (approximately 260°C) and reflow soldering (lead-free up to 260-270°C) without softening or deforming.

Long-term thermal aging stability:At operating temperatures (typically 80-125°C, or even higher), long-term use results in slow performance degradation, ensuring a long service life.

Heat-resistant deformation creepThe ability to resist slow deformation under long-term stress (such as terminal crimping force) and high temperature.

3. Reliable flame retardancy:

High flame-retardant grade:It must meet strict international safety standards, such as UL94 V-0 (typically requiring thicknesses of 0.8mm or 1.6mm), to prevent short circuits and fire spread during overheating. Halogen-free flame retardancy is an important trend.

4. Low moisture absorption and excellent electrical performance stability:

Low water absorption rate:PA66 itself is hygroscopic, and moisture absorption can lead to dimensional changes (swelling), decreased mechanical strength (especially impact strength), and deterioration of electrical properties (reduced insulation resistance, increased dielectric constant and loss factor). Electronic connectors require a low water absorption rate and stable electrical performance in humid environments (high insulation resistance, low dielectric constant, and loss factor).

Electrolytic corrosion resistance:In a humid environment, prevent electrochemical migration (CAF) between metal leads and plastic that can cause short-circuit failure.

5. Good chemical resistance:

Resist the corrosion of flux residues, cleaning agents, grease, and various environmental chemicals in resistance welding to prevent material degradation or cracking.

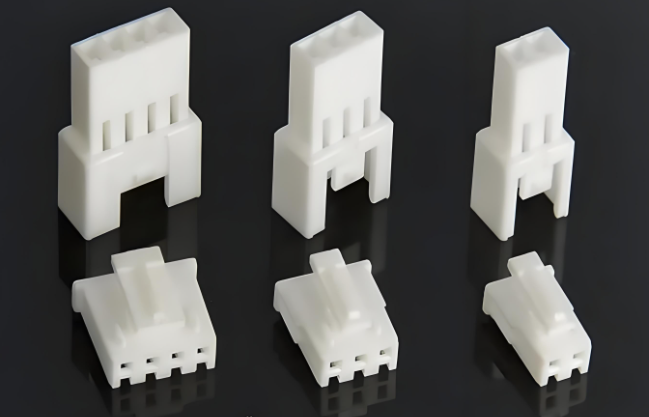

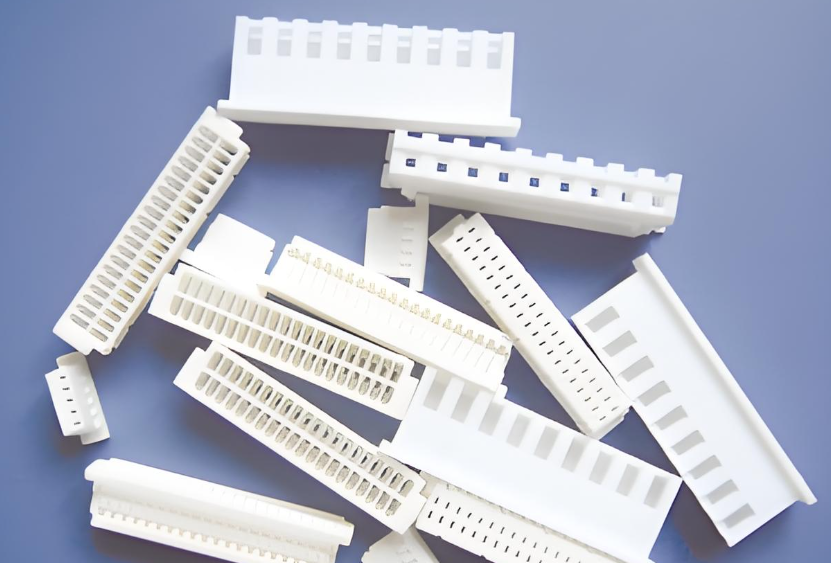

6. Excellent processing fluidity and dimensional accuracy:

Capable of filling complex, thin-walled connector structures (such as multi-pin connectors), ensuring molding efficiency and product precision (reducing defects such as flash and short shots).

Low warpage deformation to ensure assembly accuracy.

7. Good surface performance:

An appropriate surface friction coefficient facilitates plugging and unplugging operations.

Good surface quality is beneficial for electroplating (if required) or for ensuring appearance.

Scratch resistance.

2. Common Modified Formulations of PA66 Used in Electronic Connectors

To meet the above stringent requirements, pure PA66 must be modified to be qualified. Common modification formulation systems include:

1. Enhanced toughening system:

Glass fiber reinforcement:The most fundamental modification.

Function:Significantly increase strength, rigidity, HDT, dimensional stability, reduce thermal expansion coefficient, and improve creep resistance.

Dosage:The glass fiber content is usually between 15% and 50%. Low glass fiber content (15-25%) is used in applications requiring toughness; high glass fiber content (30-50%) is used in precision connectors that require ultra-high rigidity, dimensional stability, and heat resistance.

Note: Translate the above content into English and output the translation directly without any explanation.Increasing the glass fiber content will reduce impact toughness and flowability, and increase the risk of surface fiber exposure and wear on molds/pins. It is necessary to optimize the type of glass fiber (length, diameter, surface treatment) and the coupling agent.

Toughening agent:

Function:To compensate for the reduction in toughness caused by glass fiber reinforcement, especially at low temperatures and in notched impact strength, and to reduce the risk of brittle fracture.

Type:Commonly used reactive toughening agents include SEBS-g-MA (maleic anhydride grafted styrene-ethylene/butylene-styrene block copolymer), POE-g-MA (maleic anhydride grafted polyolefin elastomer), and EPDM-g-MA (maleic anhydride grafted ethylene propylene diene monomer rubber).

Dosage:It is usually between 5% and 20%, requiring a balance of toughness, strength, rigidity, and flowability. Excessive impact modifier will significantly reduce strength and HDT.

2. Flame Retardant System:

Halogen-free flame retardant:

Type:Currently the mainstream choice.

Nitrogen-based flame retardants:Melamine cyanurate (MCA) has moderate flame retardant efficiency, minimal impact on electrical properties, and relatively low cost, but its thermal stability is relatively poor (which may affect welding performance) and it has slightly higher hygroscopicity. It is often used in combination with phosphorus-based compounds.

Phosphorus-based flame retardants:Such as organophosphinates (e.g., aluminum diethylphosphinate, ADP), organophosphates/phosphonates, etc. They offer high flame retardant efficiency, good thermal stability (suitable for high-temperature soldering), low hygroscopicity, and excellent electrical properties, making them the preferred choice for high-end applications. However, the cost is relatively high.

Nitrogen-phosphorus synergistic system:MCA combined with organophosphinate or MCA combined with ammonium polyphosphate (APP) can utilize synergistic effects to improve flame retardant efficiency and reduce costs.

Dosage:According to the target flame retardant rating (V-0 thickness) and formulation system adjustments, the typical range is 15%-25%.

Requirements: Translate the above content into English, output the translation directly, no explanation needed.Must meet strict electrical performance (CTI ≥ 600V), low corrosiveness, low precipitation, good thermal stability (>300°C), low hygroscopicity, and compatibility with PA66.

Halogenated flame retardants (gradually being phased out):Brominated epoxy resin (BER) or brominated polystyrene (BPS) combined with antimony trioxide (Sb2O3) synergist. It has high flame retardant efficiency and relatively low cost but negatively impacts electrical properties (low CTI), thermal stability, and environmental friendliness. It still finds limited use in low-cost fields where halogen-free requirements are not stringent.

3. Hydrolysis Stabilizer:

Function:Inhibit the hydrolysis-induced cleavage of PA66 molecular chains under high temperature and high humidity conditions, maintaining long-term mechanical and electrical performance stability, thereby extending service life. This is crucial for connectors requiring long-term reliability.

Type:They are mainly carbodiimide compounds. They can react with carboxyl groups produced by hydrolysis, preventing chain hydrolysis reactions.

Dosage:Usually between 0.5% and 2%.

4. Lubricants and Processing Aids:

Internal lubricant:Reduce melt viscosity, improve flowability, facilitate the filling of thin-walled structures, reduce internal stress, and enhance production efficiency. Commonly used additives include stearate salts (such as calcium stearate) and lignite acid wax derivatives (E wax, OP wax).

External lubricant:Prevent melt from sticking to the mold, improve demolding performance, reduce flash, and enhance the surface finish of products. Commonly used are silicones, fluoropolymers, etc.

Nucleating agent:Promote crystallization, improve crystallinity and crystallization rate, thereby enhancing HDT, rigidity, dimensional stability, and shortening the molding cycle. Commonly used nucleating agents include talc and organic phosphates.

Antioxidant:To prevent materials from degrading, yellowing, and losing performance due to thermal oxidation during processing and use. Commonly used combinations include hindered phenols (primary antioxidants) and phosphites/thioesters (secondary antioxidants).

5. Reduce hygroscopic modifier:

Although glass fiber reinforcement itself can reduce the water absorption rate (since glass fiber does not absorb water), further modification is sometimes still required.

Blend with other low moisture absorption polymers:A small amount of PPO (polyphenylene oxide) or PPS (polyphenylene sulfide) can be used, but compatibility and cost are challenges.

Add hydrophobic fillers/additives:Specially treated mineral fillers or nanomaterials (such as modified montmorillonite) can be used, but the effects and processes need to be carefully evaluated.

A more common and effective method isManage the impact of moisture absorption by optimizing the formulation (high glass fiber content, effective flame retardant system) and adding hydrolysis stabilizers., rather than completely eliminating moisture absorption.

6. Other Functional Additives:

Anti-static agent:To prevent static electricity from attracting dust or causing discharge. Commonly used permanent antistatic agents (such as carbon nanotubes, conductive carbon black - but at the expense of insulation) or migratory antistatic agents (such as ethoxylated amines).

Colorant:To meet the demand for different colors, it must be high-temperature resistant, non-migratory, and not affect performance.

Metal passivator:To prevent metal ions from catalyzing the degradation of polymers, especially when the flame retardant contains metals (such as aluminum-based phosphorus flame retardants).

3. Typical Formula Example

Basic high-performance halogen-free flame retardant formulation:

PA66 resin: 50-60%

Glass fiber (long/short glass fiber): 25-35%

Halogen-free flame retardant (organic hypophosphite/nitrogen-phosphorus compound): 15-20%

Toughening agent (SEBS-g-MA): 5-10%

Hydrolysis stabilizer (Dicyandiamide): 1-1.5%

Lubricant/processing aid: 1-2%

Antioxidant: 0.3-0.5%

Nucleating agent (optional): 0.1-0.3%

High fluidity thin-wall application formulation:

You may need a higher proportion of PA66 (or choose a higher flow grade of PA66), appropriately reduce the glass fiber content (while still ensuring strength), optimize the lubricant system (increase internal lubrication), and select a flame retardant with good flow properties.

Ultra-high heat resistance/dimensional stability formulation:

Use a high glass fiber content (40-50%), select flame retardants with good heat resistance (such as pure organic phosphinates), add nucleating agents, and strictly control moisture and processing conditions.

4. Material Selection and Formulation Design Considerations

Performance balance:There is no perfect formula; it is necessary to find the optimal balance among strength, toughness, flowability, heat resistance, flame retardancy, and cost. For example, increasing glass fiber enhances rigidity and HDT but reduces toughness and flowability; increasing toughening agents improves toughness but decreases strength and HDT.

Material compatibility:Ensure that all additives (flame retardants, toughening agents, lubricants, etc.) are compatible with the PA66 matrix to avoid precipitation, migration, or phase separation.

Processing technology:The modified formulation must be suitable for injection molding (the most common) or other processing techniques (such as insert molding). Focus on the effects of melt temperature, mold temperature, injection speed, and holding pressure on the final product's performance (such as internal stress, crystallinity, and orientation).

Long-term reliability:The formulation design must consider the product's service life requirements by adding hydrolysis inhibitors, selecting stable systems, and verifying through rigorous long-term aging tests (such as high-temperature and high-humidity tests, temperature cycling tests).

Cost:High performance often means high cost (such as halogen-free phosphorus flame retardants, hydrolysis stabilizers, and high glass fiber content). It is necessary to optimize costs while meeting performance requirements.

Regulatory compliance:Ensure compliance with RoHS, REACH, halogen-free standards (such as IEC 61249-2-21), UL certification, and other regulatory requirements.

Supplier Selection:Select raw material suppliers (such as PA66 resin) and modified material suppliers with strong technical capabilities, stable quality, and the ability to provide comprehensive technical support (including material data, processing guidelines, and failure analysis).

Developing modified PA66 materials suitable for electronic connectors is a complex systematic engineering task that requires a deep understanding of the specific application requirements (especially welding temperature, flame retardant rating, operating environment, and expected lifespan). Based on the characteristics of PA66, performance improvement and balance can be achieved through scientifically and reasonably designed formulations, primarily involving glass fiber reinforcement, halogen-free flame retardancy, toughening, hydrolysis resistance and stability, and processing optimization. Continuous material innovation (such as new flame retardants, toughening agents, and nano-modification) and rigorous testing and validation are key to ensuring the long-term reliability of connectors.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track