Only 3%! automotive recycled plastic content remains low, special plastic view analyzes europe's automotive plastic recycling challenges and solutions

In the automotive manufacturing field, plastic components are widely used, ranging from bumpers to dashboards, and they come in various types. These plastic components account for the vehicle's mass. 14% - 18%。Zhuan Suo Shi Jie observed and found that,In the EU, the automotive industry is the third largest sector for plastic consumption in manufacturing new products, accounting for approximately total demand. 10%However, under the global wave of the circular economy, the situation of plastic recycling in new cars in the EU is not satisfactory.

Currently, on average, only about3% of the plastic is made from recycled plastic, but some models perform better, with recycled plastic content reaching up to 20%.As the EU introduces various regulations on recycled plastics for vehicles, Specialized Plastics World dissects the current state of the recycled plastics industry for automotive use in Europe and outlines some of the proposals made by companies and organizations for the development of Europe's recycled plastics industry.

Source: EU official website

Current Status of Automotive Plastics: Considerable Scale but Low Recycling Rate

Currently, EuropeNew cars use recycled plastics, approximately. 80% comes from industrial production processes. Waste plastics before production have a high degree of homogeneity, making them easier to recycle. Common polymers used in automobiles, such as polypropylene and polyurethane, are partially recyclable, but thermosetting polyacrylates are difficult to recycle. Manufacturers often do not know the recycled content when purchasing virgin plastics.

At the same time, inThe recycling rate of plastics in the scrapped vehicle processing stage urgently needs to be improved.,For example, a large car dismantling plant in Germany processes a large number of scrapped vehicles each year, but among the plastic waste generated by the vehicles, only 19% is sent for recycling, 40% is incinerated for energy recovery, and 41% is landfilled. This indicates that there is significant room for improvement in plastic recycling in the EU automotive industry.

Four Major Obstacles: Restricting the Development of Automotive Plastic Recycling

Plastic components are widely used in automobile manufacturing, from exterior bumpers to the intricate interior dashboards, and plastic is omnipresent, comprising a significant proportion of the vehicle's mass. However, the reality is not as ideal, as the EU automotive industry encounters numerous obstacles in its journey towards plastic recycling, akin to trudging through a thorny path.

European research institutions believe thatFirst, culturally,Companies are reluctant to share plastic recycling technologies and experiences for fear of losing their competitive advantage.For example, a French automotive parts manufacturer has invested a significant amount of money to develop an efficient plastic recycling process that can increase the purity of recycled plastic to Over 95%, and the recycling cost is reduced by 20%. However, the company is concerned about being imitated by competitors and has not publicly disclosed this technology, resulting in slow progress in this field for the entire industry, with other companies still using high-cost, inefficient recycling methods.

Secondly,EU member states have different waste management frameworks, and recycling infrastructure varies widely.Germany is a leader in plastic recycling technology, with advanced recycling facilities capable of precise sorting and efficient recycling of various complex plastics. In contrast, some Eastern European countries, like Romania, have relatively outdated recycling facilities that can only handle single types of plastic. This disparity makes cross-regional plastic recycling cooperation challenging. For example, a German company planned to import scrap car plastics from Romania for recycling and reuse, but the cooperation ultimately failed because Romania's recycling facilities could not sort the plastics to the level of precision required by the German company.

Source: Hexun.com

Third,In scrapped vehicles, the value of metal is high, with the focus of recycling being on metal, and sometimes the price of virgin plastic is cheaper than recycled plastic.For example, in the case of a car recycling company in the UK, when the company processes a scrapped car, the profit from metal recycling accounts for the overall profit. 70%, while the profit from recycling plastics is only 10%. At the same time, the quality of recycled plastics is unstable and lacks market competitiveness. For instance, automotive interior parts made from recycled plastics do not match the durability and aesthetics of those made from virgin plastic products, leading consumers and car manufacturers to prefer virgin plastic products.

Finally,Post-consumer plastic waste does not meet aesthetic standards, and composite materials used in the industry are also unsuitable for recycling.A car manufacturer is using a new type of composite material to produce engine hoods, which is made from a mixture of various plastics and fibers, offering high strength and lightweight properties. However, due to its complex composition, existing recycling technologies cannot effectively separate and reuse it, leaving it to be discarded as landfill waste or incinerated, thereby wasting resources and polluting the environment.

Adopt a multi-pronged approach. Promote the development of automotive plastic recycling.

For this purpose, Special Vision Discovery.European Union Joint Research Centre Researchers have proposed three complementary potential policy options.:

One is the voluntary commitment by individual car manufacturers to use recycled materials in new cars.Recyclable plastic.This approach can fully leverage the autonomy and innovation of enterprises, encouraging them to actively explore and practice in the field of plastic recycling and utilization.

Secondly, it is mandatory to collect and disclose information on plastic recycling in the vehicle manufacturing supply chain.By establishing an information collection and disclosure system, strengthen the supervision of plastic recycling in the automotive industry, prompting companies to pay more attention to plastic recycling and improve information transparency.

Third, establish mandatory targets for the use of recycled plastics in new automobiles and implement them progressively within a reasonable timeframe.A clear goal can provide a clear development direction for enterprises, guiding them to gradually increase the proportion of recycled plastic use and promoting the development of plastic recycling in the automotive industry.

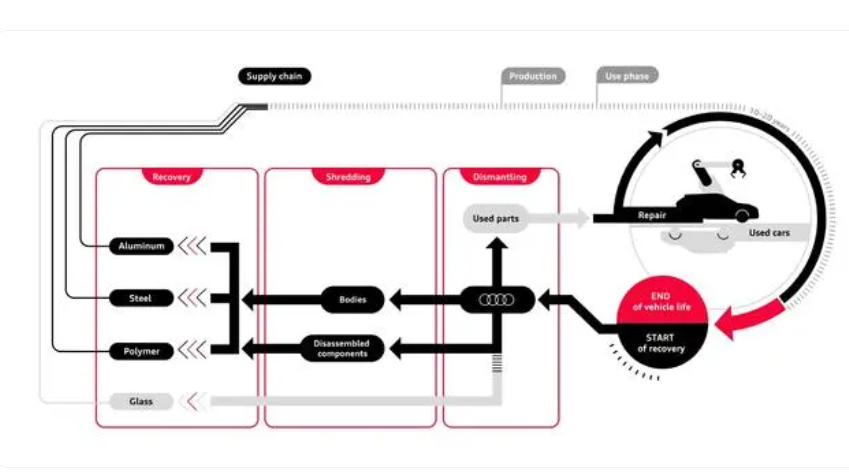

Source: Audi

The team from the European Union Joint Research Centre emphasized that these policy measures, along with any other measures, should be part of a detailed impact analysis in the decision-making process, including quantitative assessments to simulate their effects under various scenarios. They also suggested further research on the environmental impacts of plastic recycling, such as pollution and carbon emissions, and a more detailed analysis of the impacts on global material flow, or applying this approach to other materials and industries.

Epilogue:

With the gradual implementation and improvement of various EU policies, the automotive industry's plastic recycling development is expected to usher in new opportunities. Voluntary corporate commitments, information disclosure regulations, and the establishment of mandatory targets will collectively break the current impasse. Culturally, information sharing is becoming a trend, regulatory differences are gradually being bridged, economically, the competitiveness of recycled plastics is improving, and technological challenges are continuously being overcome. The EU automotive industry is sure to achieve breakthroughs in the field of plastic recycling, making significant contributions to the global circular economy.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories