Nylon PA66 Self-Lubricating and Wear Resistance: Material Characteristics, Modification Strategies, and Industrial Application Prospects

1. Basic Properties and Tribological Background of PA66

Polyamide 66 (PA66) is an important engineering plastic that, thanks to its unique molecular structure and excellent comprehensive properties, is widely used in high-tech fields such as machinery manufacturing, automotive industry, electronics, and aerospace. The molecular chains of PA66 contain strongly polar amide groups (-CONH-), which can not only form a three-dimensional network structure through hydrogen bonding, giving the material good mechanical strength, but also reduce surface friction to some extent. However, the friction coefficient of pure PA66 typically ranges from 0.3 to 0.5, and under high-speed and high-load conditions, it is prone to significant frictional heat generation and wear, limiting its application in harsh working conditions.

From the perspective of tribology, the friction and wear behavior of polymers is influenced by multiple factors in synergy, including intrinsic properties of the material (such as molecular weight, crystallinity, surface energy), the properties of the counterpart surface, and environmental conditions (temperature, humidity, medium, etc.). The friction process of PA66 is essentially a comprehensive result of interface shear, material transfer, and energy dissipation. Under high load or high-speed conditions, the heat generated at the friction interface can cause a sharp increase in the surface temperature of PA66. When it exceeds the glass transition temperature of the material (approximately 50-60°C), the mobility of the surface molecular chain segments enhances, leading to material softening or even melting, thereby exacerbating wear.

It is worth noting that PA66 has a certain degree of self-lubricating ability, which is due to the orientation and arrangement of amide groups in its molecular structure during friction, forming a surface layer with lower shear strength. However, this natural self-lubrication is limited in dry environments, so it is necessary to enhance it through material modification, surface engineering, and other methods to meet the application requirements under high loads, high speeds, or special environments.

To systematically evaluate the tribological properties of PA66 and its composites, researchers and engineers typically use a series of standardized test methods, such as the ASTM G99 pin-on-disk wear test and ISO 6602 for determining the coefficient of friction of plastics. These tests can quantify critical indicators such as the static friction coefficient (μs), dynamic friction coefficient (μk), volume wear (W), and wear depth (D) under controlled environmental parameters (temperature -40°C to 150°C, humidity 20%-80%), providing a scientific basis for material selection and optimization.

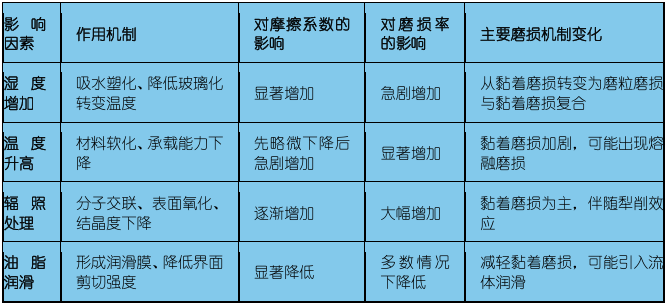

1. Humidity and water absorption effect

PA66, as a semi-crystalline polymer, contains polar amide groups and exhibits significant hygroscopicity, which has a dual impact on its tribological properties. In dry environments, the friction coefficient of PA66 is relatively high (typically in the range of 0.3-0.5), with adhesive wear being the predominant wear mechanism. When the environmental humidity increases or the material absorbs moisture, water molecules infiltrate the polymer network, acting as a plasticizer and lowering the glass transition temperature and surface hardness of the material. Studies have shown that after humidity treatment, the friction coefficient and wear rate of PA66-PA66 friction pairs increase dramatically, which is primarily attributed to the plasticization of the surface caused by moisture absorption, as well as the reduction in cohesive strength and glass transition temperature.

It is particularly noteworthy that the effect of different humidity levels on wear mechanisms exhibits a nonlinear change. Under 50% relative humidity conditions, the wear mechanism mainly manifests as a composite form of adhesive wear and abrasive wear, with abrasive wear being the most significant. However, when the humidity further increases to 70%, 90%, or even under immersion conditions, the degree of abrasive wear weakens, and adhesive wear gradually becomes dominant. This change is due to the gradient variation in the surface layer properties of the material and the differences in the lubricating effect of the interfacial water film under different humidity conditions.

The limiting PV value (the product of contact pressure and sliding velocity) of PA66 significantly decreases after moisture absorption. When the PV value under actual working conditions exceeds this reduced material limit, the degree of friction and wear increases sharply, which may lead to premature failure of the parts. This finding has important guiding significance for the design of PA66 components used in humid environments or underwater applications.

2. Temperature and Thermal Effects

During the friction process, mechanical energy is converted into thermal energy, causing an increase in the temperature at the contact interface, which significantly affects the performance of PA66. As the temperature rises, the storage modulus of PA66 decreases, the mobility of molecular chain segments increases, the material softens, and its load-bearing capacity reduces. Particularly under high-speed friction conditions, the generated frictional heat is difficult to dissipate effectively, which may lead to thermal runaway, accelerating material wear and even threatening the safe operation of equipment.

Experimental research indicates that the friction coefficient of PA66 exhibits complex behavior with temperature changes. Within a moderate temperature range (below the glass transition temperature), the friction coefficient may slightly decrease due to material softening; however, as the temperature further increases, especially surpassing the heat distortion temperature (approximately 180°C for pure PA66), the material significantly softens or even melts, resulting in a sharp increase in the friction coefficient and intensified wear.

To address the issue of frictional heat accumulation, researchers have developed PA66 composites with heat conduction-enhanced structures. For instance, by constructing an interconnected expanded graphite/stearic acid (EG/SA) network, the thermal conductivity and heat absorption capacity of the composites can be significantly improved. This design not only reduces the generation of frictional heat through a low friction coefficient but also accelerates the dissipation of the heat generated, lowering the contact temperature from 106.9°C to 40.6°C, thereby greatly enhancing the wear resistance of the material under harsh working conditions.

3. Irradiation and Environmental Aging

Gamma-ray irradiation and environmental factors can profoundly alter the molecular structure and tribological properties of PA66. With the increase in irradiation dose, cross-linking reactions occur between PA66 molecular chains, leading to an increase in gel content from 1.31% to 60.77%. At a high irradiation dose of 1000 kGy, the content of oxygen-containing functional groups on the material's surface increases, and even hydroxyl groups are generated.

The molecular structure changes induced by irradiation have a significant negative impact on the friction performance. The friction coefficient of PA66 increased from 0.49 to 0.615, and the wear rate dramatically rose from 179.3×10³ μm³/(N·m) to 2511.7×10³ μm³/(N·m). This change stems from multiple factors: the increased cross-linking of molecular chains enhanced the material's resistance to spalling during friction; the decrease in crystallinity reduced the material's load-bearing capacity and dimensional stability; and surface oxidation altered the interfacial interactions.

Interestingly, the effect of irradiation on wear morphology exhibits regional differences. In the central area of the wear scar, adhesive morphology is consistently observed; whereas in the edge area of the wear scar, the morphology shifts from adhesive to grooved as the irradiation dose increases. This difference reflects the response characteristics of irradiated modified materials under different stress conditions, offering a new perspective for understanding the friction behavior of materials in complex stress fields.

4. Influence of Lubrication Conditions

The influence of lubrication conditions on the tribological performance of PA66 is more direct and significant than that of environmental factors. Studies show that under lubrication conditions, the friction coefficient and wear rate of PA66 and its composites are generally significantly lower than under dry friction conditions. Particularly for glass fiber reinforced PA66 (PA66+33%GF), the lowest friction coefficient and wear rate are observed under grease lubrication conditions, attributed to its high strength and the effective lubricating film formed by the lubricant at the fiber-matrix interface.

However, the lubricating effect is not beneficial under all conditions. Under low PV values, the specific wear rate of PA66 and PA66+13%GF under grease lubrication is actually higher than that under dry friction conditions. This may be because the grease reduces the surface mechanical strength of these materials, making them more prone to wear. This finding reminds engineers to carefully evaluate lubrication schemes when selecting them for low-speed, light-load applications.

Different lubricating media can produce differentiated effects. Research shows that base oils containing special polar groups (such as -OH) can provide better lubrication performance for PA66 composites, which is due to the special interaction between polar molecules and the amide groups on the PA66 surface. In addition, the addition of solid lubricants like nano molybdenum disulfide to the base oil can form a friction protection film, the formation speed and thickness of which are influenced by the physicochemical properties of the base oil.

Table: Influence of Different Environmental and Working Conditions on the Friction Performance of PA66

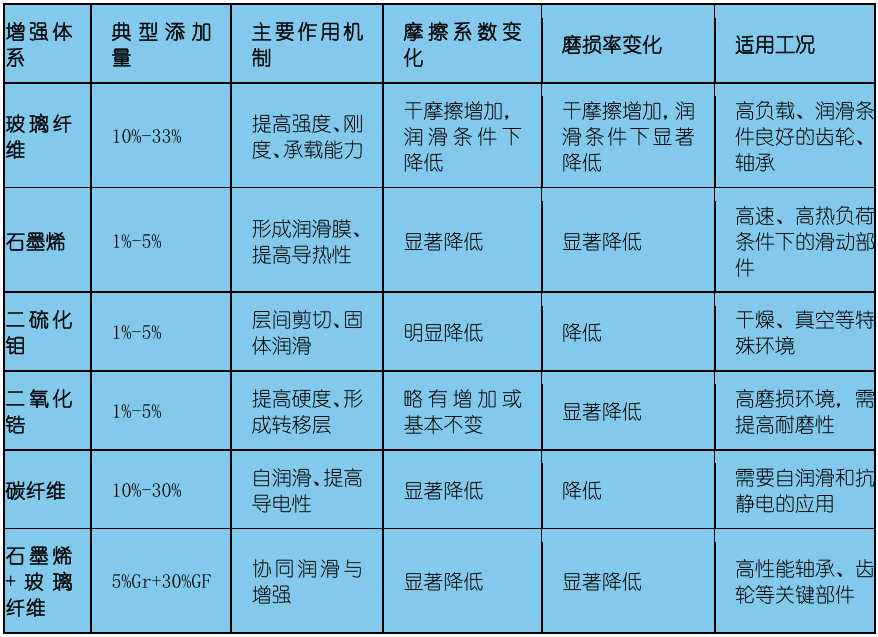

1. Fiber Reinforced System

Glass fiber (GF) reinforcement is one of the most common methods to enhance the mechanical and tribological properties of PA66. The addition of GF significantly improves the strength, stiffness, and heat distortion temperature of PA66, but its effect on tribological properties is complex and condition-dependent. Under dry sliding conditions, GF-reinforced PA66 generally exhibits a higher friction coefficient and wear rate compared to pure PA66. This is mainly because the glass fibers that peel off during sliding act as abrasive particles, causing erosion on the surface.

However, under lubrication conditions, high-strength glass fiber reinforced PA66 (such as PA66+33%GF) exhibits excellent tribological properties, with the lowest friction coefficient and wear rate. This seemingly contradictory phenomenon can be explained by the interface transfer film theory: under lubrication conditions, the surface of GF reinforced PA66 is more likely to form a stable transfer film, while the high strength of the fibers ensures the structural integrity of the composite material, preventing excessive deformation and wear.

Studies have shown that the characteristic parameters of glass fibers have a significant impact on their enhancement effect. Using a higher molecular weight PA66 matrix, smaller diameter glass fibers, and suitable glass fiber treatment agents to improve the interface adhesion between fibers and PA66 can significantly enhance the wear resistance and creep resistance of the composite material, while reducing the erosion effect of glass fibers on the steel counterpart. Smaller fiber diameters reduce stress concentration, improve the fiber-matrix interface, and thus decrease the tendency for fiber debonding during the wear process.

The initial orientation of fibers in composite materials also has a significant impact on tribological behavior. When the fiber orientation is parallel to the sliding direction, the fibers are more likely to debond from the matrix, exacerbating wear; whereas when the fibers are perpendicular to the sliding direction, they can more effectively resist wear but may increase the friction coefficient. This finding provides a theoretical basis for optimizing the friction performance of components by controlling injection molding process parameters.

2. Nano Additive Enhancement

Nanoadditives, due to their unique size effect and surface effect, provide a new approach for the fine-tuning of the tribological properties of PA66. Studies have shown that different types of nanoadditives exhibit significant differences in the mechanism and effects of improving the frictional properties of PA66.

✔ Graphene: As a two-dimensional nanomaterial, graphene exhibits outstanding mechanical properties and lubrication characteristics. When added to PA66 composites in an appropriate ratio (such as 5%), graphene nanosheets can form a continuous lubricating film at the friction interface, significantly reducing the friction coefficient. Meanwhile, the high thermal conductivity of graphene helps dissipate frictional heat, alleviating the thermal softening effect. Studies have shown that the PA66+30GF+5% graphene composite exhibits the lowest friction coefficient, and wear surface analysis has also confirmed the enhancement of tribological properties due to the addition of graphene.

✔ Zirconia (ZrO₂): As a hard nano-particle, ZrO₂ primarily improves the wear resistance of PA66 by enhancing its hardness and load-bearing capacity. Interestingly, in certain cases, the addition of ZrO₂ can result in a "negative wear" phenomenon, where the wear amount is negative due to the transfer of metal particles from the counterpart to the polymer pin. This material transfer phenomenon may form a protective transfer layer, further improving friction performance, but it may also lead to excessive wear of the counterpart.

✔Molybdenum disulfide (MoS₂): As a classic solid lubricant, the layered structure of MoS₂ allows it to easily slide under shear, thereby reducing the friction coefficient. When MoS₂ is compounded with glass fibers to reinforce PA66, a synergistic reduction in both the friction coefficient and wear rate can be observed. This results from the organic combination of the lubricating effect of MoS₂ and the load-bearing enhancement effect of glass fibers.

The dispersion state of nano-additives is crucial to their enhancement effects. Uniformly dispersed nanoparticles can effectively transfer loads, hinder crack propagation, and form a continuous lubricating film at the friction interface. In contrast, agglomerated nanoparticles may become stress concentration points, leading to early failure. Therefore, developing effective dispersion techniques and surface modification methods is key to achieving the optimal enhancement effects of nano-additives.

3. Collaborative Enhancement System

A single enhancement system often struggles to simultaneously meet multiple performance requirements. Therefore, researchers have developed various synergistic enhancement systems to achieve a comprehensive improvement in the tribological properties of PA66 through the complementary effects of different enhancement phases.

The hybrid reinforcement system of carbon fiber and glass fiber combines the self-lubricating properties of carbon fiber with the high-strength characteristics of glass fiber. The addition of carbon fiber not only reduces the friction coefficient of the composite material but also improves its conductivity and dimensional stability. Research shows that carbon/glass fiber hybrid reinforced PA66 composites exhibit excellent tribological performance when grinding against steel, regardless of lubrication.

The synergistic enhancement of nanomaterials and fibers is another promising research direction. For example, adding graphene to glass fiber-reinforced PA66 not only utilizes graphene's lubricating effect to reduce the friction coefficient but also improves interface thermal management through its high thermal conductivity, reducing material degradation caused by heat accumulation. Similarly, combining nano-ZrO₂ with glass fibers can simultaneously enhance the material's hardness, strength, and wear resistance.

Recent research has also explored enhanced systems with special structures, such as interconnected expanded graphite/stearic acid (EG/SA) networks. This design not only accelerates the dissipation of frictional heat through the thermal conductive network of EG but also utilizes the endothermic properties of SA's phase change to further control the interface temperature. EG can also adsorb SA, preventing its leakage during processing and use, ensuring long-lasting lubrication. This synergy reduces the friction coefficient of PA6 (similar in properties to PA66) composites by 74.5%, decreases the contact temperature from 106.9°C to 40.6°C, and reduces the wear rate by 90.1%. These principles are equally applicable to the optimized design of PA66 systems.

Table: Common Reinforcement Systems of PA66 and Their Impact on Tribological Properties

1. Surface texture and microstructure design

Surface texture technology, by creating regular or irregular micro-geometrical patterns on material surfaces, can effectively regulate tribological performance. For PA66 and its composites, surface texture influences friction behavior mainly through mechanisms such as changing contact area, providing lubricant storage space, and capturing wear debris. Studies have shown that under dry friction conditions, the improvement effect of surface texture on the tribological performance of PA66 composites is limited; however, under lubricated conditions, appropriate surface texture design can significantly reduce friction coefficient and wear rate.

The geometric parameters of texture, including the shape, size, depth, and distribution density of pits, have a significant impact on tribological performance. Circular pits can effectively capture wear debris and reduce three-body wear, while groove-shaped textures facilitate the delivery and distribution of lubricants, forming a continuous lubrication film. Optimizing texture design requires consideration of actual working conditions. For instance, under boundary lubrication conditions, smaller and deeper pits are more beneficial for retaining lubricants, whereas under mixed lubrication conditions, larger and shallower textures may be more effective.

It is noteworthy that the synergistic effect between surface texture and reinforcing additives. For instance, creating appropriate textures on the surface of PA66 composites containing graphene can not only store solid lubricants through the texture, but also promote the formation and stabilization of the graphene lubricating film. This combination of surface engineering and material modification offers new ideas for the development of high-performance friction materials.

2. Molecular Structure Modification

Chemical cross-linking is an effective molecular structural modification method to improve the tribological properties of PA66. By introducing covalent connections between PA66 molecular chains, the network density of the material can be increased, enhancing its resistance to plastic deformation and adhesive wear. Research shows that adding polycarbodiimide compounds can increase the molecular weight of PA66 through reactive extrusion, significantly improving the wear resistance of glass fiber-reinforced PA66 and aramid fiber-reinforced PA66 materials.

The mechanism of the effect of crosslinking modification on tribological performance is complex: on one hand, crosslinking increases the hardness and strength of the material, enhancing its resistance to plowing and micro-cutting; on the other hand, excessive crosslinking may reduce the material's toughness, increasing the tendency for brittle fracture. Therefore, controlling the degree of crosslinking is crucial, as it requires balancing wear resistance and toughness.

The latest research has also explored the application of dynamic cross-linked networks in friction materials. This network combines the stability of covalent cross-linking with the dynamic properties of reversible bonds, allowing the material to self-repair minor damage during friction and extend its service life. Although this technology is currently in the research stage for its application in PA66, it presents a new direction for the design of friction materials.

Interface engineering and transfer film regulation

During the friction process, polymer materials often form a transfer film on the opposing surfaces. The composition, structure, and adhesion of this film have a decisive impact on tribological performance. For PA66 and its composites, optimizing the characteristics of the transfer film is one of the key strategies to improve tribological performance.

Studies have shown that adding solid lubricants (such as graphite, MoS₂) or nano-fillers (such as graphene) to PA66 composites can promote the formation of transfer films with low shear strength, thereby reducing the friction coefficient. For example, graphene nanosheets, due to their two-dimensional structure and weak interlayer interactions, easily orient and align under shear forces, forming a low-friction transfer layer.

Interface chemical modification can also effectively regulate the characteristics of transfer films. By introducing specific functional groups into the PA66 molecular chain or using coupling agents to treat the reinforcement phase, the interfacial interactions between fillers and matrix, transfer films, and counterpart components can be improved. For example, treating glass fibers with silane coupling agents can not only enhance the interfacial adhesion between the fibers and PA66 but also promote the formation of stable transfer films on the fiber surface, reducing fiber peeling and abrasive wear.

Frictional chemical reactions also play an important role in the formation and evolution of transfer films. Under the influence of frictional heat and mechanical stress, the PA66 molecular chains may undergo chemical reactions such as breakage and oxidation, generating new compounds that may participate in the construction of the transfer film. By introducing specific additives to catalyze or guide beneficial frictional chemical reactions, more stable and better-lubricating transfer films can be formed.

1. Typical Application Scenarios

PA66 and its composites are widely used in various industrial fields due to their excellent tribological properties, lightweight and high strength, and corrosion resistance. They are particularly prominent in critical components requiring self-lubrication or wear resistance.

In the automotive industry, PA66 composites are widely used for manufacturing gears, bearings, bushings, and sliding components. Research shows that glass fiber reinforced PA66 (PA66+33%GF) exhibits excellent tribological performance under grease lubrication conditions, making it an ideal choice for high-load applications such as transmission gears and steering system gears. Additionally, PA66 composites with added graphene or MoS₂ can maintain low friction and low wear under dry or boundary lubrication conditions, making them suitable for components like seals and dampers that are difficult to lubricate adequately.

In the application of bearing cages, the self-lubricating property and wear resistance of materials are crucial. Systematic studies have shown that PA12-based composites outperform PA66 and PA46-based materials in self-lubricating bearing cage applications. However, with appropriate enhancement modifications, PA66 can also meet most of the requirements for bearing cages. PA66 composites with added nano-additives (such as graphene and ZrO₂) are particularly suitable for high-speed bearing cages, as these nano-additives not only reduce the friction coefficient but also improve thermal conductivity, aiding in the dissipation of frictional heat.

In special environmental applications, such as seawater lubrication conditions, PA66 composite materials also show potential. Research has found that the friction pair composed of PA66 polymer composites and 316L stainless steel exhibits acceptable friction and wear characteristics in aqueous solutions with varying salinity, providing material selection for friction components in marine engineering equipment. Additionally, by adding rubber particles (such as SEBS-g-MA), the wear resistance of PA66 under dry friction and water lubrication conditions can be improved. This toughening material is particularly suitable for friction components that endure impact loads.

2. Performance Balancing and Optimization Strategies

In practical applications, tribological performance often needs to be balanced with other performance indicators, including mechanical strength, thermal performance, processability, and cost. Designing high-performance PA66 friction materials requires a comprehensive consideration of multiple factors.

Balancing tribological performance and mechanical properties is a core challenge in material design. Increasing the glass fiber content can significantly enhance the strength and stiffness of the material, but may increase the wear rate under dry friction conditions. By optimizing fiber orientation, using small diameter fibers, and improving interface adhesion, tribological performance can be improved without significantly sacrificing mechanical properties. Additionally, adding a small amount of nano-fillers, such as graphene, can significantly reduce the friction coefficient and wear rate without notably affecting mechanical properties.

The coordination of tribological performance and thermal performance is also crucial. PA66 composites generate heat during friction, which may lead to material softening and performance degradation. By adding high thermal conductivity fillers (such as graphene, carbon fiber), thermal management can be improved, but this may increase costs and processing difficulty. Recent research has constructed interconnected thermal conductivity networks (such as the EG/SA system), enhancing heat absorption capacity by introducing phase change materials while improving thermal conductivity, achieving synergistic optimization of tribological and thermal performance.

The balance between material properties and processing performance should not be overlooked. A high filler content or special reinforcement phase may reduce the flowability of the material, increasing processing difficulty and costs. For example, high glass fiber reinforced PA66 with a high content is prone to uneven fiber orientation and distribution during the injection molding process, affecting the consistency of the final product's tribological performance. By optimizing processing parameters (such as temperature, pressure, and speed) and developing new processing technologies (such as reactive extrusion), it is possible to enhance processing efficiency and consistency while ensuring material performance.

The balance between cost-effectiveness and performance is a practical consideration in engineering applications. Advanced reinforcement phases such as graphene and carbon fibers can significantly enhance tribological performance, but they also greatly increase material costs. In contrast, traditional glass fiber reinforcement or mineral-filled solutions are lower in cost, but they may not meet performance requirements in certain harsh conditions. Therefore, material selection needs to be based on the performance requirements and cost constraints of specific application scenarios. Sometimes, a regional or layered material design (such as using high-performance materials in the friction surface area while employing lower-cost materials in the support areas) may be an economically effective solution.

3. Life Prediction and Reliability Assessment

For engineering applications, the long-term reliability and life prediction of materials are crucial. The tribological properties of PA66 composites may gradually degrade during use due to aging, wear, and environmental factors. Accurate life prediction can prevent unexpected failures and safety accidents.

Research shows that the wear process of PA66 composite materials typically goes through an initial run-in phase, a stable wear phase, and an accelerated wear phase. In the initial phase, surface roughening and transfer film formation occur; the wear rate remains relatively constant during the stable phase; and the accelerated wear phase is entered when the material is severely degraded or when there is a significant change in the opposing surface. By monitoring changes in parameters such as the friction coefficient, wear volume, and temperature, the material's condition and remaining life can be assessed.

Environmental factors significantly affect the lifespan of materials. Humidity can reduce the limit PV value of PA66, and when actual operating conditions exceed this reduced limit, wear increases dramatically. Elevated temperatures can accelerate material aging and performance degradation, especially under conditions near or exceeding the heat distortion temperature. Special environmental factors such as irradiation can also cause changes in material structure, significantly shortening its service life.

Based on these insights, various lifetime prediction models have been developed, including physical models based on wear mechanisms, empirical models based on experimental data, and predictive models based on artificial intelligence. These models comprehensively consider the effects of material properties, operating conditions, and environmental factors, providing support for engineering design and maintenance decisions. For example, by obtaining key parameters through accelerated life testing and combining them with actual operating condition data, the lifetime of materials in specific application scenarios can be predicted, optimizing replacement cycles and maintenance strategies.

1. Research Summary

PA66, as an important engineering plastic, has its tribological properties influenced by multiple factors such as material composition, reinforcement characteristics, surface conditions, and environmental conditions. Through systematic research and comprehensive analysis, the following main conclusions can be drawn:

In terms of material modification strategies, glass fiber reinforcement is a fundamental method to improve the mechanical and tribological properties of PA66, especially under lubricated conditions. The introduction of nano-additives (such as graphene, MoS₂, ZrO₂) can significantly reduce the friction coefficient and wear rate, but it requires controlling the appropriate amount of additives and ensuring good dispersion. A synergistic enhancement system that combines the advantages of different reinforcement phases can achieve a comprehensive improvement in tribological performance.

Environmental factors have a significant impact. Increased humidity can cause PA66 to absorb water and become plasticized, reducing its tribological performance. Elevated temperatures can lead to material softening and accelerated wear. Radiation can cause molecular cross-linking and surface oxidation, increasing the coefficient of friction and wear rate. In practical applications, it is essential to fully consider the impact of environmental conditions on material performance.

Surface engineering technologies, including surface texture design, molecular structure modification, and interface engineering, can significantly improve tribological performance without altering the bulk composition of materials. The combination of these technologies with material modification strategies offers more possibilities for the development of high-performance friction materials.

Performance balance and optimization are crucial in engineering applications, requiring the achievement of an optimal balance among tribological properties, mechanical properties, thermal properties, processing properties, and cost. For different application scenarios, high-performance PA66 friction materials that meet specific requirements can be developed through material selection, structural design, and process optimization.

2. Future Research Directions

Based on the current research status and industrial demand, the future directions of PA66 tribology research may include:

The development of smart friction materials, which can autonomously adjust their surface characteristics according to changing working conditions, such as releasing solid lubricants at high temperatures and enhancing surface hardness under high pressure. This adaptive feature can significantly extend the lifespan of the materials and broaden their application range.

Multiscale simulation and design, combining molecular dynamics simulations, finite element analysis, and tribological experiments, establish predictive models from microstructure to macroscopic performance to guide the design and optimization of new materials. This multiscale approach can significantly reduce trial-and-error costs and accelerate the development process of new materials.

Sustainability and recycling, as environmental awareness increases, the development of recyclable, biodegradable, or bio-based PA66 friction materials will become an important direction. Studying how to efficiently recycle PA66 friction components and how to reuse recycled materials for high-performance friction applications has significant economic and environmental value.

Tribology research under extreme conditions, such as ultra-low temperatures, ultra-high vacuum, and strong radiation, focuses on the friction behavior of PA66 in special environments. These studies are crucial for applications in high-tech fields such as aerospace and nuclear energy, and will also drive the further development of tribological theory.

In summary, significant progress has been made in the tribological research of PA66 and its composites, but there are still many challenges and opportunities. Through interdisciplinary collaboration and innovative thinking, we hope to develop superior, intelligent, and sustainable friction materials to support the development of modern industry.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories