Nylon Flame Retardancy: Halogenated vs. Halogen-Free Differences

In the flame retardant modification of nylon, "halogenated" and "halogen-free" are two fundamentally different technical approaches.

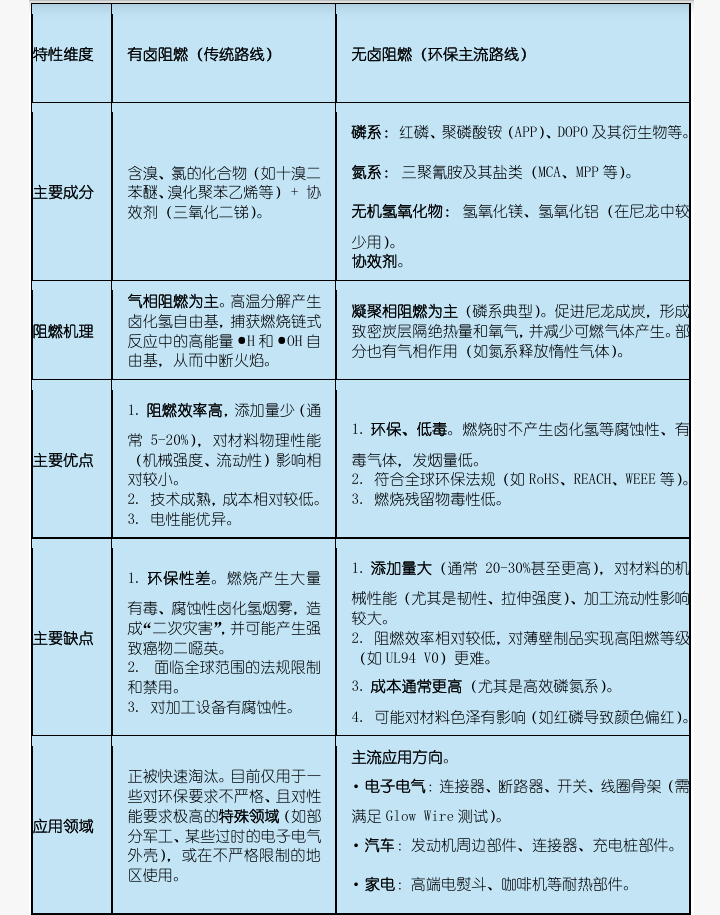

Table: Core Differences Overview

1. Differences in flame retardant mechanisms

This is the fundamental difference between the two.

Halogen-free flame retardantActs like a "chemical fire extinguisher." It releases active free radical inhibitors in the flame zone, "snuffing out" flames through gas-phase chemical action. Highly efficient, but leaves behind toxic "chemical residue" (gas).

✔Halogen-free flame retardant (phosphorus-based example) : It's like a "physical shield". It promotes the formation of a hard, porous, expanded carbon layer on the material surface. This carbon layer isolates the internal material from the exchange of oxygen and heat, thereby achieving flame retardancy. It's safer, but requires enough "building materials" (flame retardants) to build this shield, hence the large addition amount.

2. Impact on Environment and Safety

This is the core driving force behind the transition from "halogenated" to "halogen-free."

✔Fire SafetyIn building or vehicle fires, up to 80% of casualties are caused by the inhalation of toxic smoke. Burning halogenated flame retardant materials produceHydrogen halide gases are highly corrosive and toxic., severely endangering human lives and corroding rescue equipment. Halogen-free flame retardant materials offer significant advantages in this regard.

✔Ecology and HealthSome brominated flame retardants possessPersistence, Bioaccumulation, and Toxicityaccumulate in the environment and food chains. Therefore, regulations in many countries, such as the EU RoHS Directive, explicitly restrict the use of many brominated flame retardants.

3. Impact on the properties of nylon material itself

Nylon (especially PA6, PA66) is a crystalline engineering plastic that is sensitive to additives.

✔Contains halogen. The addition amount is small, usually existing in the form of "encapsulation" or "dispersion" in the nylon matrix, which causes less damage to the crystalline structure of nylon itself, thus maintaining its high strength, high toughness, and good processing fluidity.

✔Halogen-free system: Especially large additions of inorganic or phosphorus-nitrogen flame retardants can severely… Disrupts the ordered arrangement of nylon molecular chains, hindering crystallization.Material:

Rigid increase, but toughness and impact strength significantly decrease.(becomes brittle).

Melting point decreases, heat distortion temperature decreases. 。

Melt viscosity increases, and fluidity deteriorates., injection molding is difficult.

Easily absorbs moisture, electrical performance may be affected.

Technological development trends

Current research and application hotspots to overcome the drawbacks of halogen-free flame retardancy include:

Synergistic compounding technology Compounding different types of halogen-free flame retardants (such as phosphorus-nitrogen and phosphorus-inorganic) to create a "1+1>2" synergistic effect, thereby reducing the total dosage.

Polymerization/Caging Develop high molecular weight flame retardants (such as high molecular weight ammonium polyphosphate, DOPO derivatives) to improve their thermal stability and reduce migration and precipitation during processing.

3. Surface Modification/NanotechnologySurface-treating flame retardant particles to improve their compatibility with the nylon matrix. Utilizing nano-sized flame retardants (e.g., nano layered double hydroxides) to achieve significant flame retardancy with minimal additive amounts.

Intrinsically flame retardant nylon Starting from molecular design, synthesizing novel nylons with inherent flame-retardant structures (such as phosphorus-containing or aromatic ring-containing semi-aromatic nylons like PPA, PA6T) represents the most advanced development direction.

The transition from "halogenated" to "halogen-free" fundamentally represents an inevitable transformation in the materials industry, shifting from "pursuing high-performance efficiency" to "pursuing green safety and sustainable development."

If you need traditional solutions that are highly efficient, low-cost, and not subject to environmental regulationsHalogenated flame retardants still have technical advantages, but their application scope is increasingly shrinking.

For the vast majority of modern manufacturing, especially in sectors like exporting electronics, electrical equipment, automobiles, and high-end appliances. ,Halogen-free flame retardancy is the only choice. This requires you to fully consider its impact on mechanical properties, processing technology, and final cost during design, and may necessitate recipe optimization and process adjustments to address challenges.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories