Non-Toxic Polyurethane Developed for the First Time Using Plant Waste and CO₂

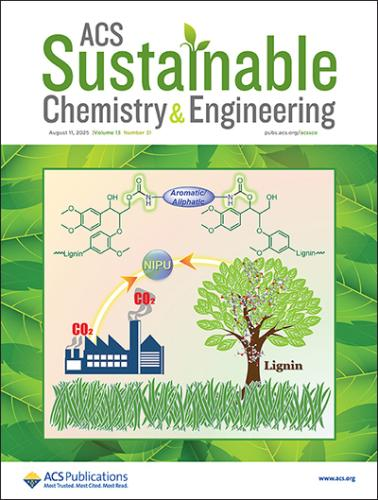

Traditional polyurethane production relies on isocyanates, which are highly reactive and hazardous chemicals. A breakthrough approach transforms plant lignin and carbon dioxide into strong, safe polyurethane without the use of dangerous chemicals.

Polyurethane is widely used in various industrial fields such as automotive parts, construction materials, furniture, and coatings due to its ability to regulate heat, maintain flexibility during processing, and retain strength in its final form.

Traditional polyurethane production relies on toxic isocyanates, which are highly reactive hazardous chemicals, while the new method developed by the team completely eliminates the use of such substances.

"Using fewer steps, lower energy consumption, and zero toxic raw materials, high-quality polymers were produced." Dr. Hoyong Chung, the team leader, stated that the new product retains the strength, heat resistance, and processing flexibility of traditional materials, while being more easily soluble in solvents, addressing the processing difficulties of biomass-based materials.

Raw lignin powder and lignin-based polyurethane samples in Dr. Hongzhong Ho's laboratory at the Interdisciplinary Research and Commercialization Building, Florida State University. (Scott Holstein/FAMU-FSU College of Engineering)

In terms of raw materials, lignin, a common waste product from the pulp and paper industry, has been converted into a high-value material; carbon dioxide, as a greenhouse gas, is directly incorporated into the polymer structure, achieving "turning waste into treasure." "Scalability is very important. Our method involves fewer steps and can produce materials of equal or better quality at a lower cost," added Chung.

This novel polyhydroxyurethane has a molecular weight ranging from 182.4 to 248.7 kDa. Thermogravimetric analysis (TGA) indicates that the polyurethane exhibits good thermal stability, with a 5% weight loss temperature (Td5%) of 248–259°C. Differential scanning calorimetry (DSC) shows a glass transition temperature (Tg) of 45–73°C. In terms of mechanical stability, the maximum stress at 10% strain reaches up to 69.17 kPa, and the highest modulus is 691 kPa.

The team has long been accumulating research on lignin, having used it to produce polycarbonate in 2024, and this time expanding to the more widely applied polyurethane. The research was conducted in the Interdisciplinary Research and Commercialization Building at Florida State University, supported by the U.S. Army Research Office and related Korean departments, with postdoctoral fellow Arijit Ghorai as the first author. The team is currently advancing the commercialization of the technology and exploring sustainable synthesis methods for more polymers.

(From left) Dr. Arijit Ghorai and Dr. Hoyong Chung pose for a photo inside the Interdisciplinary Research and Commercialization Building (IRCB) in Tallahassee, Florida, on August 12, 2025. The research team used lignin and carbon dioxide to create a new type of biodegradable polyurethane that is free of toxic chemicals. (Scott Holstein/FAMU-FSU College of Engineering)

(From left) Dr. Arijit Ghorai and Dr. Hoyong Chung pose for a photo inside the Interdisciplinary Research and Commercialization Building (IRCB) in Tallahassee, Florida, on August 12, 2025. The research team used lignin and carbon dioxide to create a new type of biodegradable polyurethane that is free of toxic chemicals. (Scott Holstein/FAMU-FSU College of Engineering)

https://pubs.acs.org/doi/10.1021/acssuschemeng.5c02064

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories