[New Material Weekly] Plite's Performance Explodes! High-End Polyester Raw Material Project to Start Trial Production

Major news this week: The volatile capital market has drawn significant attention. PRET's performance has exploded, with 9 major bases accelerating its global layout. LCP and sodium batteries are opening up new growth space for the company, and the estimated net profit attributable to the parent company in 2025 is expected to surge by 155.76%-194.73% year-on-year.

In the tech sector, three robot companies were handpicked for the Spring Festival Gala, signaling a departure from the "performance era" for domestic robots and showcasing rapid iteration and fierce competition. Meanwhile, the US Oak Ridge National Laboratory has developed a new 3D printing extrusion system, achieving breakthroughs in both speed and precision.

In industry dynamics, Hanjian River & Mountain's cross-industry acquisition of a PEEK leader unveils the tip of the iceberg in the booming PEEK track. China National Petroleum Corporation's Dushanzi Petrochemical Company's POE adaptability modification project has achieved breakthroughs, providing stable and reliable domestic alternatives for the photovoltaic industry. ... For more industry news, please read this issue of [Weekly New Materials & Plastics Express].

Big Tech Dynamics

Pulis's performance explodes! 9 major bases accelerate globalization, LCP and sodium-ion batteries open up new growth spaces.

On the evening of January 26th, Pulit (002324.SZ), a leading modified materials company, released its 2025 annual performance forecast, delivering a brilliant report. The company expects a full-year net profit attributable to the parent company of RMB 361 million to RMB 416 million, a year-on-year surge of 155.76%-194.73%; the year-on-year increase in net profit excluding non-recurring items is even higher, reaching 206.2%-257.87%.

Female billionaire Xiong Haitao has been placed under detention! She is the actual controller of Easun Technology, Dongcai Technology, and High Polymer Materials, and the wife of the founder of Kingfa Science & Technology.

On the evening of January 27, 2026, the capital market was hit with a major announcement: YiChang Technology (002420), Dongcai Technology (601208), and Gaomeng New Material (300200) issued announcements disclosing that Xiong Haitao, the actual controller and vice chairman of the companies, had been placed under detention and investigation by the supervisory authority.

Tianyancha shows that Dongcai Technology, Yichang Technology, and Gaomeng New Material, three listed companies, all have Gaoxin Technology Industry Group Co., Ltd. as their largest shareholder.

CCTV Spring Festival Gala highlights three robotics companies! Chinese robots are officially moving beyond the "performance era."

On January 23rd, Magic Atoms was the first to officially announce its strategic partnership with the Spring Festival Gala for intelligent robots in the Year of the Horse (Note: This likely refers to a Chinese zodiac year, probably an error in the original text and should be clarified). The collaboration of two major robotics companies with the Spring Festival Gala within a mere three days not only outlines a new profile of technological elements for the Gala but also reflects the rapid iteration and fierce competition in China's embodied AI robot track.

New 3D Printing Extrusion System is Here! May Replace Traditional Extruders, Already Used for Car Bumper Production

According to Plastics Insight, a new 3D printing extrusion system developed by Oak Ridge National Laboratory (ORNL) achieves a breakthrough in both speed and precision by integrating multiple extruders into a single high-output stream through a specially designed nozzle.

Traditional large extruders are heavy and require expensive gantries or robots for support. Furthermore, they tend to suffer from decreased precision and unstable flow rates in low-extrusion volume scenarios. This necessitates reduced printing speeds when fabricating small parts to prevent heat buildup and subsequent warping.

Han Jianheshan Cross-Border Acquisition of PEEK Leader! PEEK Track Sparks Collective Gamble

Recently, A-share listed company Hanjian Heshan (stock code: 603616) released a terse suspension announcement: it plans to acquire a 52.51% stake in a New Third Board company called "Xingfu New Material."

At first glance, these two companies seem completely unrelated: Hanjian Heshan's main business is cement pipes, and it has been involved in water conservancy projects for years; while Xingfu New Materials deals in high-end chemical materials, with its core product being the intermediate for PEEK (polyetheretherketone), hailed as "plastic gold."

Yet it is precisely this cross-industry combination that has unexpectedly revealed a glimpse into the booming PEEK sector. Recently, NHU (Xinhantex), a domestic leader in the production of DFBP—the core monomer for PEEK—acquired a 51% stake in Hyrit Engineering Plastics, which possesses a production capacity of over 200 tons of PEEK resin, for approximately 13 million yuan. Looking back from the vantage point of 2025, such cases have become even more frequent.

POE breaks through again! Photovoltaics' cost reduction welcomes a new support point, core material costs are expected to fall significantly.

Zhuansu Vision learned from China National Petroleum Corporation (CNPC) on January 26th that China National Petroleum Corporation Dushanzi Petrochemical Company's POE adaptability modification project has achieved a historic breakthrough, producing nearly 60,000 tons of POE products throughout the year. This marks the successful large-scale production of China's independently developed gas-phase POE products.

More critically, the company's gas-phase process is a domestic first. Compared to the internationally mainstream solution-based process, its energy consumption is only 60% of the latter, and the production process involves no solvent emissions and low product volatile organic compounds (VOCs), perfectly aligning with the photovoltaic industry's green and low-carbon development needs. The key indicators, such as transmittance, of its core grade UL0588 have reached international advanced levels. Photovoltaic encapsulants manufactured using it exhibit excellent performance in weather resistance and water vapor barrier properties, providing a stable and reliable domestic alternative solution for the photovoltaic industry.

Indorama exits Czech rPET joint venture

Indorama Ventures has sold its 85% stake in Czech-based UCY Polymer to minority shareholder Maximilian Josef Söllner, through his affiliated company UCY Global Invest, for zero consideration. The joint venture was established in 2022 when the Thai chemical group acquired the majority stake in UCY, aiming to expand its recycled PET (rPET) recycling capacity by leveraging waste bottle material collected through the German Deposit Return Scheme (DRS).

Production Capacity Dynamics

Breaking the foreign monopoly! A 600-million-yuan high-end polyester raw material project is about to start trial production; 47% is not the end.

The overall civil engineering of the high-end polyester raw material project of Xuchang Jinmengjucai Technology Co., Ltd. has been fully completed and has now entered the equipment installation phase, with an installation progress of 80%. All main structures of the project will be completed before February 15th, officially entering the production preparation and trial operation stage, with plans to produce qualified products in March.

It is reported that the project involves a planned investment of 600 million yuan. Leveraging Jinmeng Jucai's independently developed advanced production technology and core catalysts from Jinmeng Industrial's Shanghai R&D Center, and utilizing the hydrogen resource advantages of Shoushan Carbon Materials Co., Ltd., the project aims to build a production facility for high-end polyester raw materials with an annual capacity of 30,000 tons, along with supporting public and auxiliary facilities. Once operational, the project will effectively fill the gap in domestic industrial application of relevant technologies and provide core support for the development of the high-end polyester industry.

1.275 billion! Synthetic biology manufacturing lands in Fuyang, Zhejiang!

Recently, the biomanufacturing enterprise Boxiao Biotech announced the commencement ceremony for its industrialization and supporting research institute project.

As a key provincial industrial project with a total investment of 1.275 billion yuan, the project is expected to complete the construction of its Phase I core production and supporting facilities between January 2026 and June 2027, and successfully commence operations.

Upon reaching full production capacity, the facility will achieve an annual output of 156.2 tons of active pharmaceutical ingredients (APIs), 300 million tablets/capsules of finished formulations, and 15 million vials/bottles, with projected annual sales exceeding 5 billion yuan and annual profit and tax exceeding 500 million yuan.

The 200,000-ton EVA plant will not be built and will be converted to projects such as ultra-high molecular weight polyethylene and polyolefin elastomers.

Due to changes in market demand, Shaanxi Yanchang Petroleum Yulin Coal Chemical Co., Ltd. has optimized its downstream processing routes. While maintaining the 300,000 tons/year vinyl acetate co-production unit unchanged, the original 200,000 tons/year ethyl acetate unit and 200,000 tons/year EVA unit have been changed to a 30,000 tons/year ultra-high molecular weight polyethylene unit, a 50,000 tons/year vinyl oil unit, a 50,000 tons/year α-olefin unit, and a 100,000 tons/year polyolefin elastomer unit. The modified project was re-registered with the Yulin Municipal Administrative Approval Service Bureau on January 24, 2025 (Project Code 2206-610836-04-01-293862).

Clariant CATOFIN™ Catalyst and CLARITY™ Platform: Dual-Engine Drive

Clariant, a focused, sustainable and innovative specialty chemical company, today announced that its CATOFIN™ catalyst continues to perform excellently in two propane dehydrogenation (PDH) units at Fujian Meijing Petrochemical Co., Ltd. (Meijing Petrochemical). In parallel, Clariant's advanced digital service platform, CLARITY™, has been successfully implemented in the first unit, with deployment in the second unit currently underway. This marks a new phase in the strategic cooperation between the two companies in olefin production.

Zhongjing Petrochemical is a subsidiary of Zhongjing Petrochemical Group, which primarily operates in energy, petrochemicals, logistics, and packaging industries. It is China's largest producer of biaxially oriented polypropylene film (BOPP). At its global largest alkane integrated production base in Fuzhou Jiangyin Port City Economic Zone, two propane dehydrogenation units, each with an annual capacity of 1 million tons, both utilize CATOFIN technology and Clariant's customized catalyst technology. They were successfully commissioned in May 2024 and May 2025, respectively. This has positioned the base among the global leaders in terms of single-unit scale, single-plant output, and total production capacity.

Wenzhou Wenyu New Material's 8.7-meter Bruckner BOPP production line successfully put into operation.

On January 28, 2026, at 9:00 AM, the second high-end German Brückner BOPP production line of Wenzhou Wenyu New Material Co., Ltd. was officially completed and put into operation. This 8.7-meter-wide, world-leading film production line, after half a year of precise debugging, successfully achieved mass production. This marks Wenyu New Material's completion of a dual-line high-end production capacity layout and its entry into a new stage of large-scale, high-quality development of functional films.

Total Investment of 2 Billion! HuiDe New Materials' 600,000-ton Polyurethane Project Commences Construction, Breaking Foreign Monopoly and Empowering New Energy

Recently, Jiangsu Huide New Material Co., Ltd. officially commenced construction of its annual 600,000-ton polyurethane new material project in the Taixing Economic Development Zone. This marks the beginning of an industrial layout with a total investment of 2 billion yuan to be implemented in three phases. The project will not only fill the domestic production capacity gap in high-end polyurethane but also provide new momentum for localized materials in multiple industries, including new energy and home furnishings.

New Arrivals

Trevira® CS Eco fabrics can now be made from textile-recycled, permanently flame-retardant fibers and yarns.

Renowned flame-retardant fabric Trevira CS has launched Trevira® flame-retardant fibers and filament yarns containing 50% recycled textile materials. The first customers were introduced to this new product at the Heimtextil trade fair in Frankfurt, Germany, in mid-January.

Toray Achieves Double Breakthrough: World's First Heat-Resistant OPP Film and Highly Antistatic ABS Resin Simultaneously Launched

Toray recently announced the successful development of a new Torayfan biaxially oriented polypropylene (OPP) film. This product is the world's first OPP film with high-temperature resistance comparable to some engineering plastics, marking a significant technological breakthrough. Toray has now commenced sample delivery of this material. The new film exhibits excellent thermal dimensional stability and release properties even at high temperatures of 160℃. It is positioned as a high-heat-resistant release film and can be applied in process scenarios such as integrated circuit (IC) substrate molding and carbon fiber reinforced plastic prepregs, which are currently dominated by fluoropolymer films.

INEOS launches RecycI-IN polymer with 70% recycled content to support sustainable cosmetic packaging

INEOS has launched a new RecycI-IN polymer grade, rPP1025C, which contains 70% recycled content and offers a high-performance, compliant and low-carbon solution for the cosmetics packaging sector.

INEOS Olefins & Polymers Europe has announced a new grade to its RecycI-IN range, demonstrating the company’s commitment to driving sustainability in the plastics and packaging industry. The new RecycI-IN compound, containing 70% recycled content, is specifically designed to meet the stringent requirements of packaging for sensitive cosmetic applications. With this innovation, INEOS aims to help brands increase the recycled content of their packaging without compromising product quality, performance, or aesthetics.

Innovative Applications

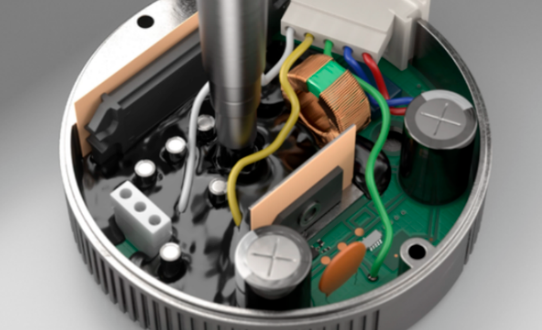

Henkel Launches New Generation of Polyurethane Potting Solutions to Enhance Reliability of Industrial and Power Electronics Equipment

Henkel has launched a new generation of two-component polyurethane encapsulant, Loctite STYCAST US 8000 A/B. This product is specifically designed for harsh environments, offering excellent electrical insulation, mechanical durability, and long-term reliability. It further enriches Henkel's portfolio of high-performance encapsulating materials, providing strong support for customers seeking advanced protection solutions for critical industrial and power electronic components.

Evonik launches transparent polyamide based on recycled plastics for sunglass production

Evonik introduces a transparent polymer made from recycled plastics. This product, called TROGAMID® R, is processed and manufactured by Poliplastic SRL, an innovative polymer recycling company. This recycling company has established a unique circular economy partnership with a high-end flat sunglass lens manufacturer to obtain scrap pieces generated during the production process.

The initial raw material for TROGAMID® R is TROGAMID® material offcuts generated during the regular production of high-end eyewear. TROGAMID® is a highly durable, crystal-clear polyamide material developed by Evonik, belonging to a series of high-performance materials widely used in premium eyewear products. In addition to TROGAMID® R, this series also includes TROGAMID® eCO grades – products made using the mass balance approach, with bio-based raw materials accounting for up to 100%.

Rosti Doubles Down on Medical and Life Science Plastics Production with Two New ISO Class 8 Cleanrooms in the US

Rosti, a globally renowned plastic injection molding company and manufacturing service provider from Sweden, has announced the construction of new ISO Class 8 cleanrooms at its two production facilities in Germantown, Wisconsin, and Clearfield, Utah, USA. In a press release, the company stated that this investment will further expand the Rosti Group's medical product manufacturing footprint in North America, while also demonstrating the company's steadfast commitment to providing customers with high-precision, regulatory-compliant, and standardized production environments.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

New 3D Printing Extrusion System Arrives, May Replace Traditional Extruders, Already Producing Car Bumpers