Modified Human Collector's Guide: A Comprehensive Overview of Plastic Hardness Testing Systems

在塑料材料的研究与应用中,Hardness is a key indicator of a material's resistance to indentation, scratching, and abrasion. It is the core embodiment of the durability and surface damage resistance of plastic products. From soft elastomers for cushioning and sealing to high-rigidity polymers for structural components, hardness directly determines the application scenarios of materials.

What is plastic hardness?

From a physics definition, the hardness of plastic refers to the material's resistance to indentation by a harder object. It is typically observed that harder materials will abrade or scratch softer materials. In characterization, hardness is a dimensionless property, meaning it has no specific physical unit.

II. Why are hardness indicators so important?

Core Engineering Parameters: 在设计消费电子、工业零件或家用电器时,硬度是结构设计的基石。特别是在考虑表面外观受损(如划痕、失光)时,硬度决定了产品在摩擦或运动接触下的表现。

Material property evaluation Hardness testing can indirectly assess a material's surface quality, strength, wear resistance, and heat treatment effectiveness.

适用性筛选: 帮助工程师判断某种改性配方或后处理工艺是否符合特定的终端应用。

Failure Prevention and Quality InspectionHardness testing is a fast, non-destructive quality control method that can effectively verify batch consistency and reject non-conforming parts.

三、 塑料硬度的主流测量

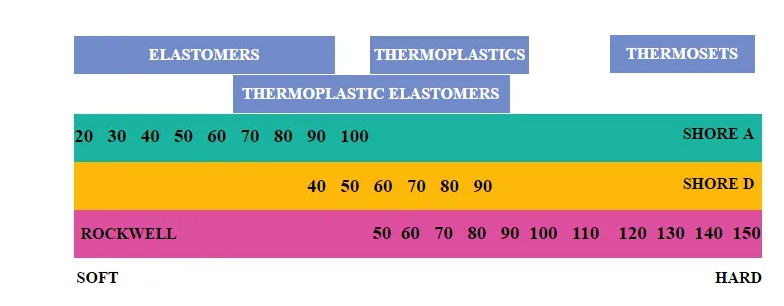

Due to the wide range of plastics, from very soft to very hard, a single scale cannot cover them all. Currently, the industry primarily uses the following two systems:

Rockwell hardnessRockwell Hardness is based on measuring the depth of indentation. By applying different loads or using different indenters, Rockwell hardness is divided into multiple scales (indicated by letters). The higher the value, the harder the material.

适用范围: 常用于测试较硬的工程塑料,如 PA (Nylon), PC (Polycarbonate), PS (Polystyrene) 等。

Common Rulers: Rockwell E, M, R。

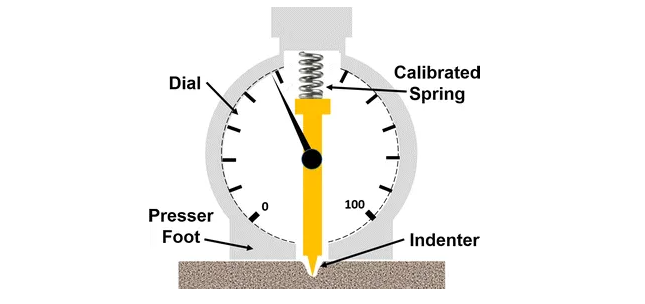

2. Shore hardness Shore hardness measures a material's resistance to indentation using a Shore durometer.

适用范围: 邵氏 A(Shore A)和邵氏 D(Shore D)是改性行业最常用的标尺。

Shore A: Primarily used for rubber/elastomers and soft plastics (such as TPE, TPV, soft PVC).

Shore D: Mainly used for hard plastics (such as PP, PE, rigid PVC, etc.).

邵氏硬度计基本原理图(来源:ResearchGate)

IV. How to Choose the Right Hardness Scale?

The choice of hardness scale often depends on industry standards, regional customs, or specific application areas.

For beginners, it is recommended to refer to the data sheets or technical literature of the target industry.

注:虽然洛氏与邵氏硬度之间存在对应关系,但由于测试原理不同,行业内通常不建议进行跨标尺的硬度换算,而应直接参考相应标准的测试结果。

V. Common International Testing Standards

ISO 2039-1: Plastics — Determination of hardness — Part 1: Ball indentation method

ISO 2039-2: Plastics -- Determination of hardness -- Part 2: Rockwell hardness method.

ISO 7619-1: Rubber, vulcanized or thermoplastic — Determination of indentation hardness (Shore hardness method).

ASTM D785: Standard Test Method for Rockwell Hardness of Plastics and Electrical Insulating Materials.

ASTM D2240: Standard Test Method for Rubber Property—Durometer Hardness.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories