Metal 3D Printing New Technology: AI-Driven Beam Shaping and Multispectral Imaging, InShaPe Generation Efficiency Increased Sixfold

Polar Bear has learned that the EU-funded InShaPe project has announced a major research breakthrough, successfully increasing the production efficiency of metal 3D printing by six times, while reducing manufacturing costs by 50%, significantly lowering energy consumption and material waste, and greatly improving the quality of components.

International Cooperation Bears Fruit

The InShaPe project, led by the Technical University of Munich (TUM), brings together 11 partners from 8 countries and has received 7.2 million euros in funding from the EU Horizon Europe program. After three years of intensive research and development, this consortium has successfully developed a revolutionary process optimization method for laser powder bed fusion metal (PBF-LB/M), perfectly combining AI-driven beam shaping technology with multispectral imaging (MSI).

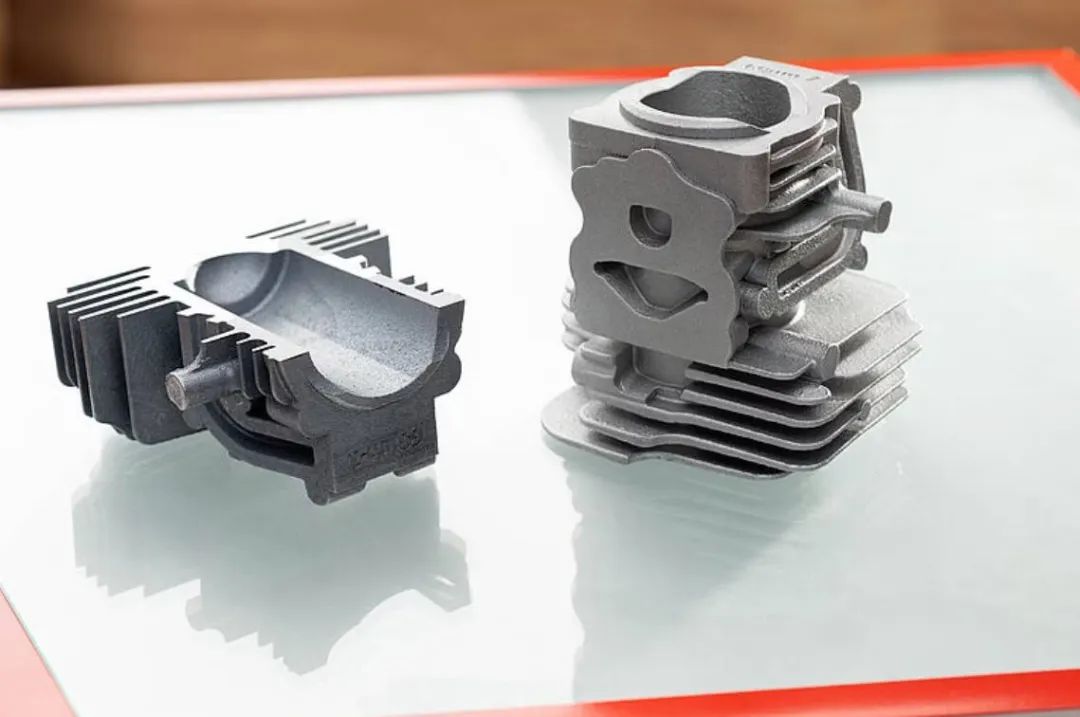

Cylinder head of the engine of a handheld chainsaw

Technical innovation addresses industry pain points

The traditional PBF-LB/M process has unique advantages in manufacturing complex metal parts, but the rigid laser beam and outdated process monitoring often lead to high defect rates and severe energy waste. The InShaPe project has completely addressed these pain points through technological innovation.

The core breakthrough of the project lies in replacing the traditional Gaussian beam with an annular beam, which can be precisely adjusted according to the geometry and material properties of each component. This intelligent laser beam profile control creates a more stable molten pool environment, significantly reducing common defects such as cracks and spatter, while markedly improving processing speed and material utilization efficiency.

The introduction of multispectral imaging (MSI) systems adds another important function to this technology. MSI systems can capture thermal signals at different wavelengths to monitor the molten pool status in real time. Any process issues can be identified and located at the earliest moment, thereby immediately triggering corrective actions to minimize production delays and rework losses.

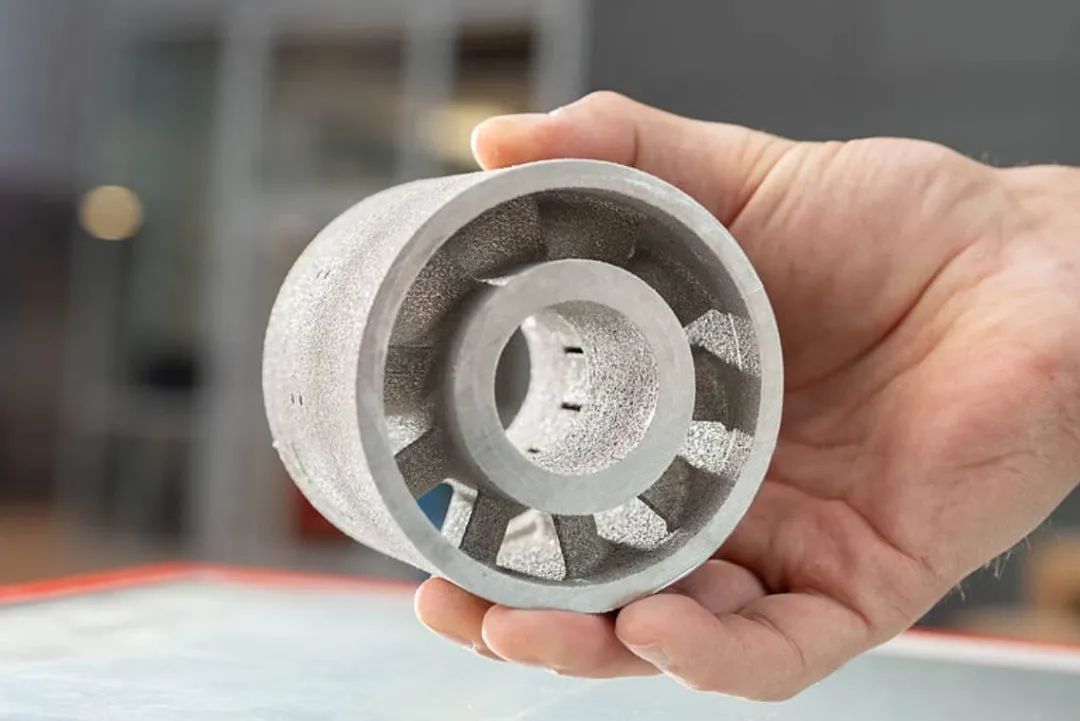

△Industrial gas turbine components used in the energy sector

Five major industrial application feasibility verification technologies

To verify the practicality of the technology, the project team conducted in-depth testing in five representative industrial application scenarios.

●Aerospace impeller

●Gas turbine components (made of Inconel 718 alloy)

Combustion chamber components in the energy field (CuCrNb material)

Handheld chainsaw engine cylinder head (AlSi10Mg aluminum alloy)

Satellite antenna components

The test results are remarkable: productivity increased from 15 cubic centimeters per hour to 93.3 cubic centimeters per hour, achieving a 6.2-fold improvement, while manufacturing costs were simultaneously reduced by 50%. These figures fully validate the effectiveness of the technology and its potential for industrialization.

Project Outlook

The success of InShaPe technology has made PBF-LB/M technology promising for application in industrial fields, especially in areas such as aerospace, energy, and automotive, where there is a strong demand for high-performance components. Project coordinator, Professor Katrin Wudy from the Technical University of Munich, stated that both academia and industry have shown great interest in this technology. It is expected that the technology will soon be put into industrial use and play an important role in improving process control and quality assurance.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track