Lego's Failed OEM Attempt: Why Hasbro Chooses OEM?

Lego's failed outsourcing attempt

After experiencing a major financial crisis, on June 20, 2007, LEGO announced to its employees that most of its manufacturing operations would be outsourced to the electronic manufacturing service provider Flextronics over the next three years.

Flex Mexico

The outsourcing decision means that the existing production line of the LEGO Group's subsidiary in Enfield, Connecticut, will gradually shut down in the first quarter of 2007 and be relocated to Flextronics' production base in Mexico. The U.S. distribution business will also be moved accordingly. Product lines with higher technical complexity (LEGO Technic and Bionicle series) will remain in production at LEGO's own factory in Billund, while the production line for LEGO System products will be transferred to Flextronics' Eastern European base. This adjustment means that the relocation work will be completed in phases over the next three years, from 2007 to 2010.

Lego Kladno

Furthermore, Flextronics will take over the operations of the LEGO Group's Kladno factory in the Czech Republic starting August 1, 2006. The factory will continue to play a key role in the production of LEGO system products.

After the outsourcing is completed, the total number of LEGO Group employees is expected to be reduced to about 3,000, a significant decrease compared to the 8,300 employees before the restructuring began at the end of 2003. In addition to production outsourcing, the sale of LEGOLAND parks, the outsourcing of European distribution operations, the closure of the Swiss factory, and layoffs globally due to a streamlined business model have all contributed to the adjustment in workforce size.

This decision is based on a deep analysis of the group's supply chain system, with a focus on optimizing the cost structure and leveraging geographical advantages close to major markets. According to this decision, the company will adopt differentiated production strategies for different product categories in the future.

Therefore, products with labor-intensive decoration, assembly, and packaging processes will be outsourced, including the Dabo series products produced by Flex's Hungary factory.

In the future, standardized LEGO bricks (LEGO system products) will also be produced and packaged by Flex in Eastern Europe and Mexico. These products are suitable for outsourcing due to their high level of standardization and high production volume, while the packaging process is notably labor-intensive. Previous experience with capacity transfer shows that both automated and labor-intensive processes can be successfully outsourced. As a result, the LEGO Group will fully benefit from the advantages of low labor costs in all production phases, unaffected by the degree of automation in specific areas.

The high-tech and highly specialized LEGO Technic and Bionicle series products will continue to be produced independently by the LEGO Group at the Billund factory.

The Bilong base will also retain a considerable scale of mechanical engineering departments and production technology research and development units to ensure the continuous enhancement of the technical capabilities that are crucial for product development.

Lego President and CEO Jørgen Vig Knudstorp stated: "This is the last major initiative in the supply chain restructuring process that began in 2004, aimed at reducing total production costs by 1 billion Danish kroner. So far, we have achieved cost savings by closing factories in Switzerland and South Korea, implementing lean production to improve efficiency, optimizing procurement processes, and simplifying product complexity. Through this restructuring, we aim to enhance profitability while strengthening our competitive advantage in an increasingly intense market."

Regarding the reasons for choosing Flex, Knudstorp pointed out: "Through our outsourcing collaboration with Flex for our products over the past year, we recognize the value of Flex as a professional partner. They understand and respect the unique values represented by LEGO products, especially the utmost pursuit of product quality and safety – which is the foundation for creating high-quality play experiences."

This attempt failed quickly and tragically, and the collaboration between both parties ended after just two years. Moreover, looking back now, it is clear that LEGO's decision at that time was indeed correct. So, what were the reasons for the failure of the collaboration back then?

The main issues include:

1. Quality control was out of control. LEGO realized that by handing over its core manufacturing technology, the subcontractors were unable to meet LEGO's stringent standards in terms of compatibility, color consistency, and precision.

2. Supply chain management mishaps. Flextronics struggled to cope with the surging market demand, leading to inventory shortages and lost sales opportunities. Forecasting errors and chaotic warehousing management continuously plagued the collaboration.

3. Lack of production flexibility. The outsourcing model lacks the agility to quickly adjust production volume and product mix, a critical flaw that becomes particularly evident when LEGO's sales exceed expectations.

New Manufacturing Strategic System

After terminating outsourcing cooperation, LEGO restructured a more resilient and flexible supply chain system through building its own production capacity and regionalized production model.

Quality and accuracy control rights recovery

LEGO is bringing all key manufacturing processes back in-house to maintain its reputation for consistently delivering high-quality products.

The company is investing heavily in building its own automated smart factory to ensure that the injection molding process and product consistency meet perfect standards.

Build a localized and flexible supply chain.

LEGO strategically establishes self-operated factories in key global markets, including Denmark, Hungary, Mexico, China, and Vietnam.

Localized production effectively reduces the risk of global supply chain disruptions while lowering transportation and timeliness costs.

Enable the company to flexibly respond to changes in regional market demand.

Focus on Core Competitive Advantages

By internalizing production, LEGO firmly controls its most valuable assets—product design and innovation capabilities.

Enterprises can focus their resources on creative research and development while ensuring that proprietary manufacturing technologies are protected.

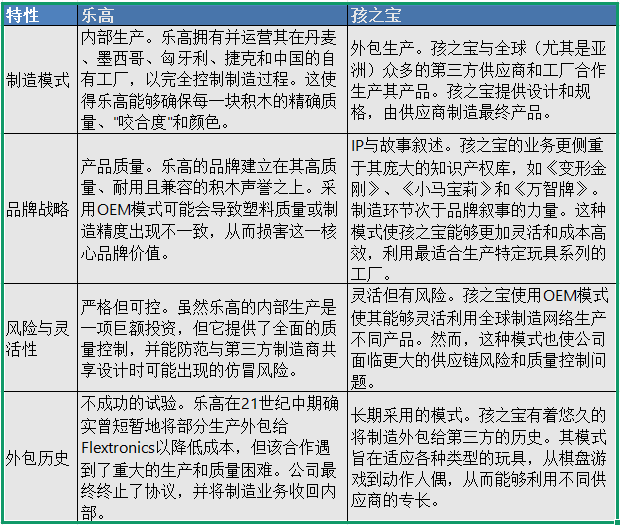

LEGO does not adopt the original equipment manufacturer model like Hasbro for two key reasons: first, its differentiated brand strategy focused on quality control; second, its unique business model based on intellectual property.

LEGO VS. Hasbro

Hasbro adopts OEM agreements for production, while LEGO focuses on in-house manufacturing and brand control, which is why LEGO does not use the OEM model. Hasbro, as a publicly traded company, tends to favor external collaboration and cost efficiency, which may include the use of OEM; whereas LEGO's private ownership and strict intellectual property protection allow it to maintain greater control over the entire production process.

In short, LEGO learned through a painful lesson that for a brand that prides itself on quality, in-house production is the strategic cornerstone for maintaining a competitive advantage.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track