Inspired by Prehistoric Woven Baskets, University of Michigan Invents New Material

Knitted materials can withstand repeated compression without deformation and can be used to manufacture robots, exoskeletons, automotive parts, building components, and more.

According to foreign media reports, engineers at the University of Michigan have drawn inspiration from prehistoric basket-weaving techniques and discovered that woven materials can recover their original shape after repeated strong compression, whereas continuous sheets of the same material deform permanently. The related research paper was published in the journal *Physical Review Research*. The modular platform used in the paper to assemble woven joints can be applied to any field where elasticity and stiffness are crucial, including soft robotics, automotive components, and architectural structures.

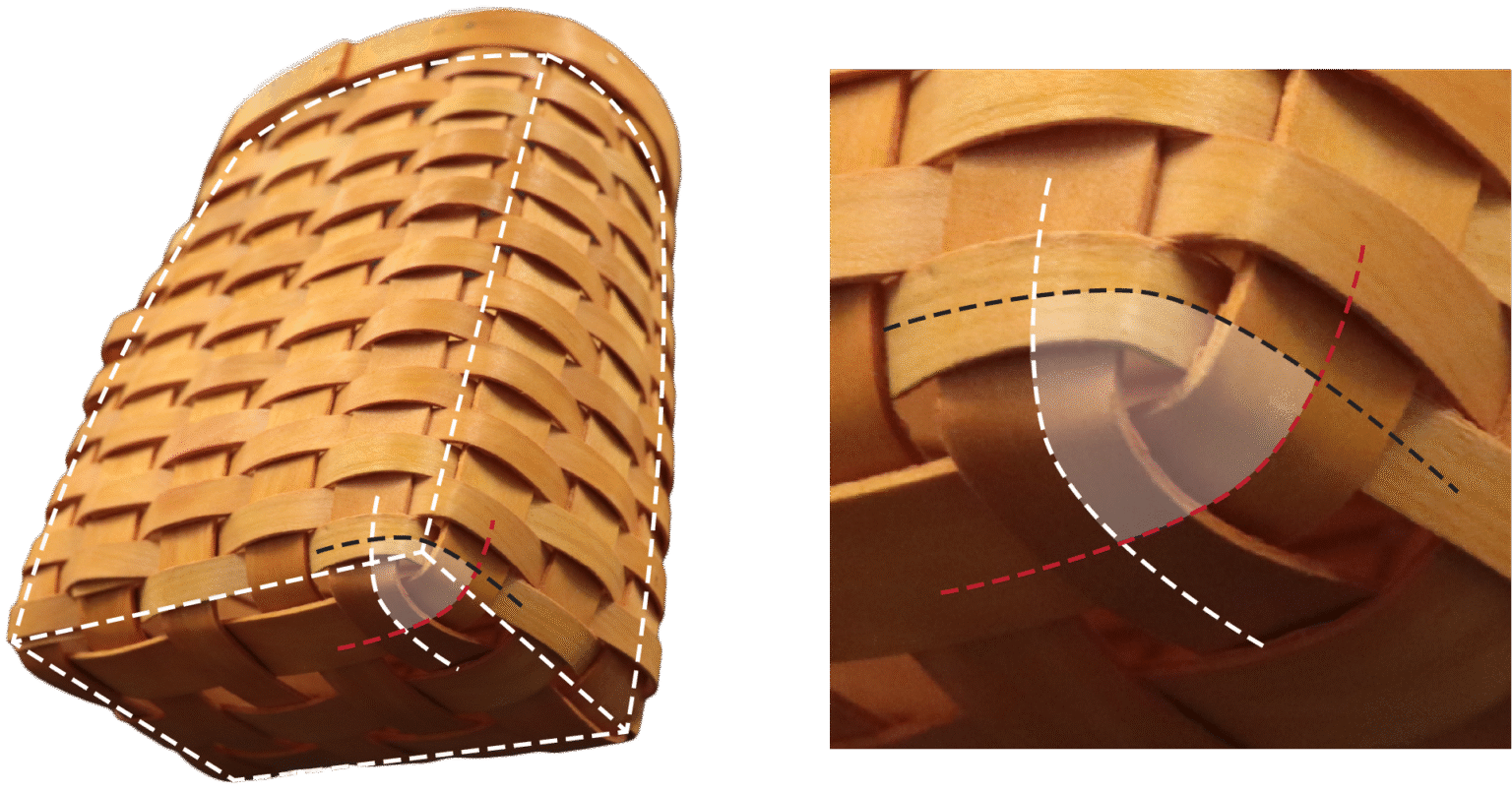

Image source: University of Michigan

Guowei Wayne Tu, the first author of the paper and a Ph.D. student in Civil and Environmental Engineering at the University of Michigan, accidentally came across an article tracing the origin of basket weaving back to around 7500 BC. Researchers began to ponder whether there are reasons beyond geometry and aesthetics that have allowed this ancient craft to endure to the present day.

“We know that weaving is an effective method to create 3D shapes using strip-like materials such as reeds and bark, but we suspect that there must be inherent mechanical advantages,” said Evgueni Filipov, associate professor of civil and environmental engineering and mechanical engineering at the University of Michigan, and the corresponding author of the study.

This study reveals these mechanical advantages: high stiffness, suitable for bearing loads; high resilience, suitable for long-term use. "I am very pleased to be able to apply the advantages of ancient woven baskets to the modern engineering field of the 21st century," Filipov added. "For example, lightweight woven materials used in robots can also help make humans safer during human-machine collisions."

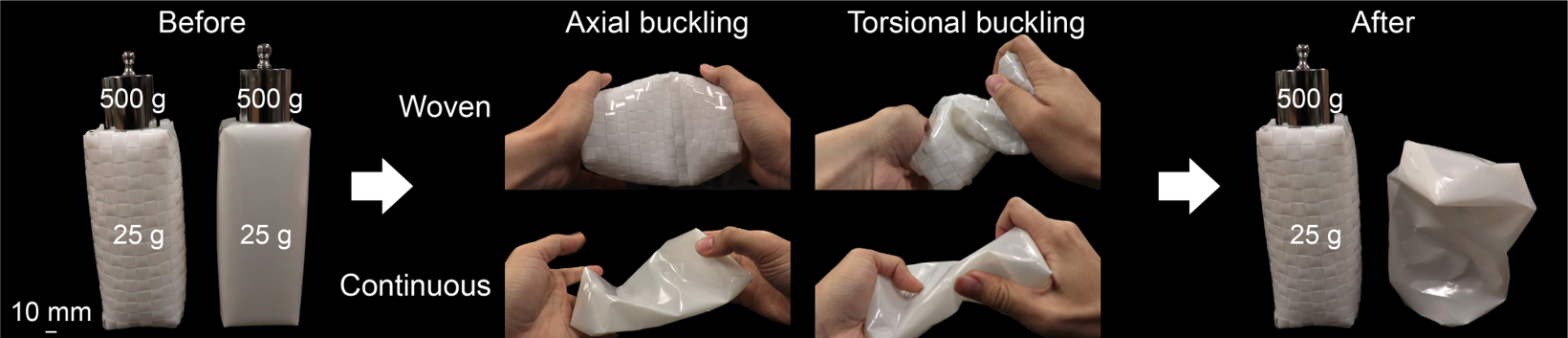

To test mechanical properties, the research team vertically wove polyester film strips (approximately the width of a pinky finger and the thickness equivalent to two sheets of copy paper) together to assemble a three-dimensional structure. They transformed this two-dimensional weave into a three-dimensional metamaterial—a type of synthetic composite material whose structure imparts physical properties not found in natural materials.

Tu stated: "While modern metamaterials are usually designed for electromagnetic, optical, or acoustic properties, people have been manufacturing mechanical metamaterials through weaving and other structural methods for thousands of years."

The structures adopted four different angular arrangements, combining three, four, five, and six planes, respectively. For comparison, the team assembled the same structures with continuous non-woven polyester films. They then tested them by gradually compressing both types of structures.

A pair of rectangular boxes with a height of 17 cm returned to their original shape after being compressed by 1 cm. When compressed further, the continuous structure was permanently damaged, while the woven structure remained intact even when compressed by 14 cm (less than 20% of its original height).

High-resolution 3D scanning identifies points of material bending deformation caused by stress concentration on continuous structures. In contrast, woven structures redistribute the stress over a larger area, thereby preventing permanent damage.

The research team then studied stiffness, which was measured by the force required to compress the structure from the top or to bend it by pushing from the side. They compared four corner structures with a continuous structure made of the same polyester film. In all experiments, the stiffness of the woven material was 70% that of the continuous material, which overturns the misconception that woven systems are inherently flexible.

In testing more complex configurations, an L-shaped structure similar to a robotic arm can vertically support 80 times its own weight—like lifting a heavy bag at the waist—and can bend upward as easily as a human arm.

Image source: University of Michigan

A quadruped woven robot prototype, referred to as "Dog" by researchers, can withstand 25 times its own weight while still being able to move its legs and walk. When overloaded, the woven dog robot returns to its original shape and can bear the same weight again.

"Using these basic angular modules, we can design and easily create woven surfaces and structural systems with complex spatial geometries that are both rigid and flexible. These angle-based woven structures have great potential in future engineering design," Tu said.

As one of its applications, researchers have designed a concept of a woven exoskeleton that can adjust the hardness of different parts of the body, thereby providing a reusable shock absorption function while in motion.

Looking to the future, we hope to integrate active electronic materials into these woven structures, enabling them to become “smart” systems that can sense the external environment and change shape according to different application scenarios," Filipov said.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track