Innovative applications and challenges of polymer composite 3d printing in civil infrastructure

As the construction industry transitions towards sustainability, automation, and digitalization, polymer composites (PCs) combined with 3D printing technology are becoming a significant driving force for innovation in civil engineering. This technology not only enables the efficient fabrication of complex engineering structures but also significantly reduces material waste, offering new possibilities for future infrastructure development. Based on the latest research from the journal *Automation in Construction*, this article systematically explores the current applications, real-world cases, and future development trends of polymer composites in 3D printing, while analyzing existing technical challenges and potential solutions.

1. Material System and Printing Technology

1. Classification of Polymer Matrices

In terms of material selection, polymer composites are mainly divided into two categories: thermoplastics and thermosets. Thermoplastic polymers such as PLA, ABS, and PEEK have become the preferred materials for 3D printing due to their recyclability and ease of processing. Among them, PLA, as a biodegradable material, has environmental advantages, but its heat resistance and impact resistance are poor, necessitating performance enhancement through modification techniques. In contrast, ABS, with its excellent impact resistance and higher glass transition temperature, is more suitable for outdoor structural components. High-performance materials like PEEK and ULTEM are widely used in infrastructure projects in extreme environments due to their outstanding high-temperature resistance, mechanical strength, and chemical stability. Thermosetting polymers are formed through photopolymerization techniques (such as SLA/DLP); although they possess excellent heat resistance and dimensional stability, their irreversible cross-linked structure makes recycling difficult, limiting their application in sustainable construction. Additionally, the introduction of recycled polymers like PET and HDPE further reduces environmental burden, but the performance degradation issues caused by multiple processing still need to be addressed.

2. Enhanced Composites

In terms of enhanced materials, fiber-reinforced polymer (FRP) composites stand out. Glass fiber (GFRP) has become an ideal choice for cyclic load structures due to its high cost-performance ratio and excellent fatigue resistance. Carbon fiber (CFRP), on the other hand, occupies an important position in precision structural components due to its extremely high strength-to-weight ratio and low thermal expansion coefficient. At the same time, the introduction of natural fibers (such as bamboo and hemp) gives composites biodegradable properties, but issues such as poor moisture resistance and weather resistance still need to be addressed. The addition of particulate reinforcement materials like silica and alumina further enhances the stiffness and wear resistance of the composites, while the introduction of carbon-based materials improves electrical conductivity, providing possibilities for the development of multifunctional structures.

3. Large Component Printing Technology

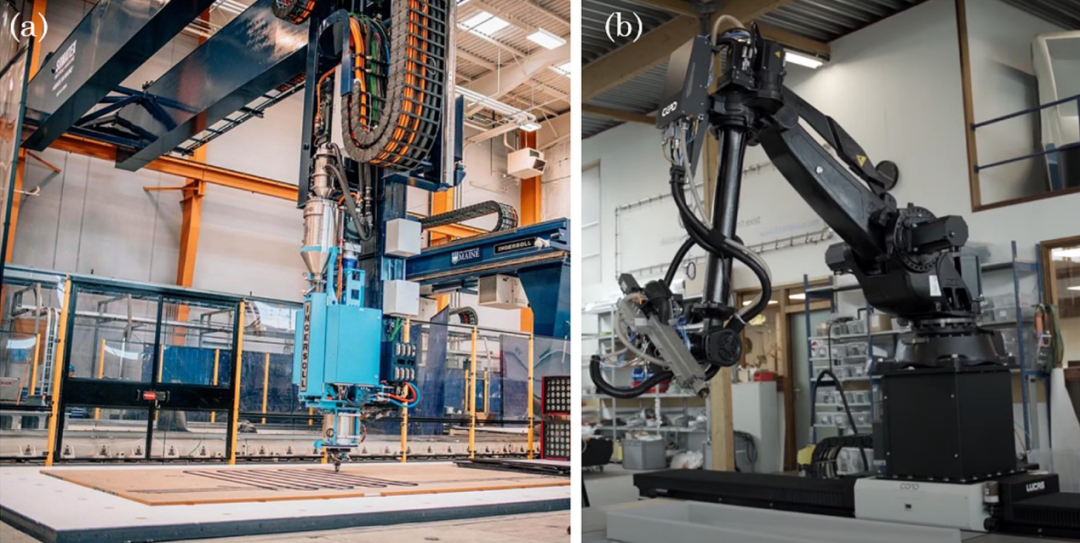

In the field of large component manufacturing, 3D printing technology exhibits unique advantages. Extrusion-based 3D printing (E3DP) is currently the most widely used technology in civil engineering, capable of handling concrete, ceramics, and various thermoplastic materials to meet the manufacturing needs of large-scale structures. The binder jetting technology effectively avoids thermal deformation issues by layer-by-layer binding of powder materials (such as gypsum and cement). The introduction of robotic manufacturing systems (RLFAM) enables support-free printing of complex geometries through multi-axis robotic arms and supports continuous fiber reinforcement, opening new avenues for the manufacturing of high-performance structures.

Figure 1 (a) The world's largest polymer 3D printer developed by the Advanced Structures and Composites Center at the University of Maine, (b) The CEAD company Flexbot large-scale robotic 3D printing and milling system.

II. Innovative Application Cases

Bridge Engineering

Practical engineering cases have fully demonstrated the tremendous potential of this technology. In bridge construction, a 6.5-meter span pedestrian bridge in Rotterdam, Netherlands, was made using glass fiber reinforced PET material, achieving a 50% reduction in carbon footprint while showcasing excellent durability. The Liu Yun Bridge project in China utilized ASA-3012 material and completed the printing of a 17.5-meter long bridge in just 35 days, withstanding severe environmental tests thanks to its weather resistance.

Figure 2 3D printed fiber-reinforced composite material cases: (a) pedestrian bridge in Rotterdam, Netherlands, (b) pedestrian bridge in the Limerick area, Netherlands, (c) 3D printed FRP components of the Liuyun Bridge, China.

2. Architectural Structure

In the field of architecture, the American BioHome 3D project uses 100% wood fiber and bio-resin for printing, completing the entire construction in just 48 hours, with all materials being recyclable. Australia's Jindi modular housing project innovatively uses recycled plastic as its core material, covered with a cement layer, addressing the issue of plastic pollution while meeting fire safety requirements. The 3D-printed houses developed by Azure in Los Angeles can be completed in just 24 hours per 200-square-foot module, while also consuming 150,000 discarded plastic bottles, providing a new approach to urban waste management.

Figure 3 3D printed fiber-reinforced composite building: (a) BioHome 3D house developed by the Advanced Structures and Composites Center at the University of Maine, (b) Azur tiny house in the United States.

Reinforcement and Seismic Resistance

In the field of structural reinforcement, 3D printing technology has also made remarkable contributions. The application of carbon fiber reinforced PLA reinforcement has improved the energy dissipation capacity of concrete beam-column joints after high-temperature damage by 40%. Additionally, concrete slabs reinforced with continuously 3D printed carbon fiber/nylon grids have demonstrated a significant increase in shear modulus, providing a new solution for seismic reinforcement of building structures.

Three, Core Challenges

However, this technology still faces numerous challenges. Firstly, the layer-by-layer deposition manufacturing method leads to anisotropic mechanical properties of the materials, and insufficient interlayer bonding strength directly affects the load-bearing capacity of the overall structure. Secondly, there are significant environmental durability issues; ultraviolet radiation and moisture erosion can accelerate the aging of natural fiber composites, while the fire ratings of most polymer materials often fail to meet building safety standards. Furthermore, there are bottlenecks in large-scale production; large printing equipment requires substantial space and has low production efficiency, as printing a 5,800-kilogram bridge, for instance, may take continuously 30 days to complete. In addition, the lack of industry standards results in a lack of unified specifications for the design, certification, and quality control of 3D printed structures. Finally, the issue of material recycling urgently needs to be addressed, especially since the closed-loop recycling technology for thermosetting polymers and fiber-reinforced composites is not yet mature.

Four. Future Directions

Looking to the future, breakthroughs need to be achieved in multiple areas. Process optimization is the primary task; developing multi-axis printing and in-situ consolidation technology is expected to improve interlayer bonding strength, while combining additive manufacturing with traditional subtractive processes can enhance forming precision. The integration of smart materials will endow structures with new functions, such as embedding sensors for health monitoring or using self-repairing polymers to extend service life. The research and development of sustainable materials is also crucial; the promotion and application of bio-based polymers and natural fiber composites will significantly reduce carbon emissions in the industry. For specific application scenarios, such as maritime engineering, customized solutions that are corrosion-resistant and flood-resistant need to be developed. Finally, policy-driven support is essential; establishing a comprehensive performance database and lifecycle assessment standards will provide institutional guarantees for the promotion of technology.

V. Conclusion

In summary, the 3D printing technology for polymer composites is reshaping the field of civil engineering through its unique capabilities in customized design, lightweight advantages, and rapid construction. Although challenges such as performance consistency, environmental durability, and large-scale production still exist, with advancements in material innovation, process improvements, and the establishment of standard systems, this technology will undoubtedly play a more critical role in future infrastructure development, providing key technical support for achieving a sustainable and high-performance built environment. In practical cases, CFRP composites have achieved tensile strengths of over 500MPa, GFRP's flexural strength can reach 200MPa, and the use of recycled PET materials can reduce virgin plastic consumption by 70%. The production process of bio-based PLA can decrease energy consumption by 60%. Although robotic printing can reduce the cost of complex components by 30%, the current material costs are still higher than traditional concrete, which will be a key area for future breakthroughs.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track